Processing method for prolonging shelf life of instant box convenience rice at normal temperature

A technology for instant rice and processing methods, which is applied in the field of fresh-keeping and storage processing of agricultural products, which can solve problems such as inconvenient transportation, sales or final consumption, high requirements for processing environment and storage conditions, complex production technology, etc., and reduce follow-up The probability of processing microbial contamination, rapid cooling and uniform cooling, and the effect of reducing precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

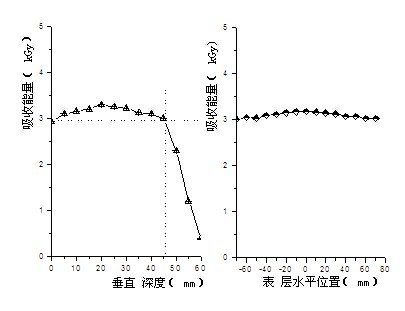

[0018] According to the processing method of boxed ready-to-eat instant rice in the manual, select northeast rice (japonica rice) with an amylose content of 16.3%, wash the rice, put it into a polypropylene box with a thickness of 1.5mm, and control the height not to exceed 30mm, add 1.15 times the water for soaking, the soaking temperature is 50°C, and the soaking time is 60 minutes, then put it in the steaming cabinet for cooking, the cooking temperature is 100°C, and the time is 25 minutes. 1000Pa, time 5min, the absolute pressure of the vacuum degree in the second stage is controlled at 2KPa, time 10min, after that, it is sealed and sealed, and put into high-energy electron beam equipment for sterilization treatment. The sterilization parameter is that the output energy of the electron beam is 5MeV , the distance between the high-energy electron beam scanner and the boxed rice is 520mm, the scanning frequency is 420pps, the scanning width is 8.6A, and the transmission speed...

Embodiment 2

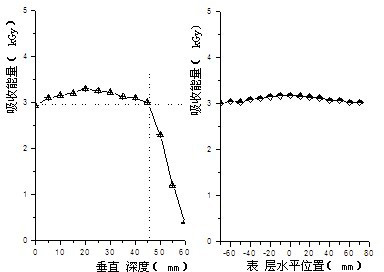

[0020] According to the processing method of boxed instant rice in the manual, select Hunan rice (indica rice) with an amylose content of 21.3%, wash the rice, put it into a polypropylene box with a thickness of 1.5mm, and control the height not to exceed 35mm, add 1.2 times the water for soaking, the soaking temperature is 50°C, the soaking time is 60 minutes, then put it in the steamer for cooking, the cooking temperature is 100°C, the time is 20 minutes, vacuum pre-cooling is carried out after cooking, the absolute pressure of the vacuum degree in the first stage is controlled at 500Pa, time 5min, the absolute pressure of vacuum degree in the second stage is controlled at 3KPa, time 10min, after that, seal the polypropylene film and put it into the high-energy electron beam equipment for sterilization treatment. The sterilization parameter is the output of the electron beam The energy is 5MeV, the distance between the high-energy electron beam scanner and the boxed rice is 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com