Production process of polyurethane polishing pad

A production process, polyurethane technology, applied in grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of uneven wear and tear, uneven distribution of polyurethane, and the inability to accurately control the size of microcellular foaming, etc., to achieve Not easy to deform and meet the effect of high flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

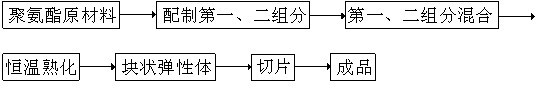

[0015] see figure 1 , the invention provides a kind of production technology of polyurethane polishing pad, comprises steps:

[0016] (1) Add 80g of liquid curing agent dimethylthiotoluenediamine and 20g of solid rubber vulcanizing agent di-o-chlorodiphenylamine methane into a stainless steel tank, mix at a constant temperature of 130°C, and cool the obtained liquid mixture to room temperature , 100g of the mixed solution is added to the mixing tank, and the mixer is stirred, and 0.9g of water is added to the mixed solution being stirred with a measuring cup, and stirred for 1min, and then 0.9g of catalyst dimethylaminoethoxyethanol is added to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com