Method for preparing nano mullite powder from coal-based kaolin

A technology for coal-based kaolin and mullite powder, which is applied in the field of nanomaterials or ceramic materials, can solve the problems of no single-phase nanomullite powder, etc., and achieves the effects of short cycle, easy availability and uniform crystal size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

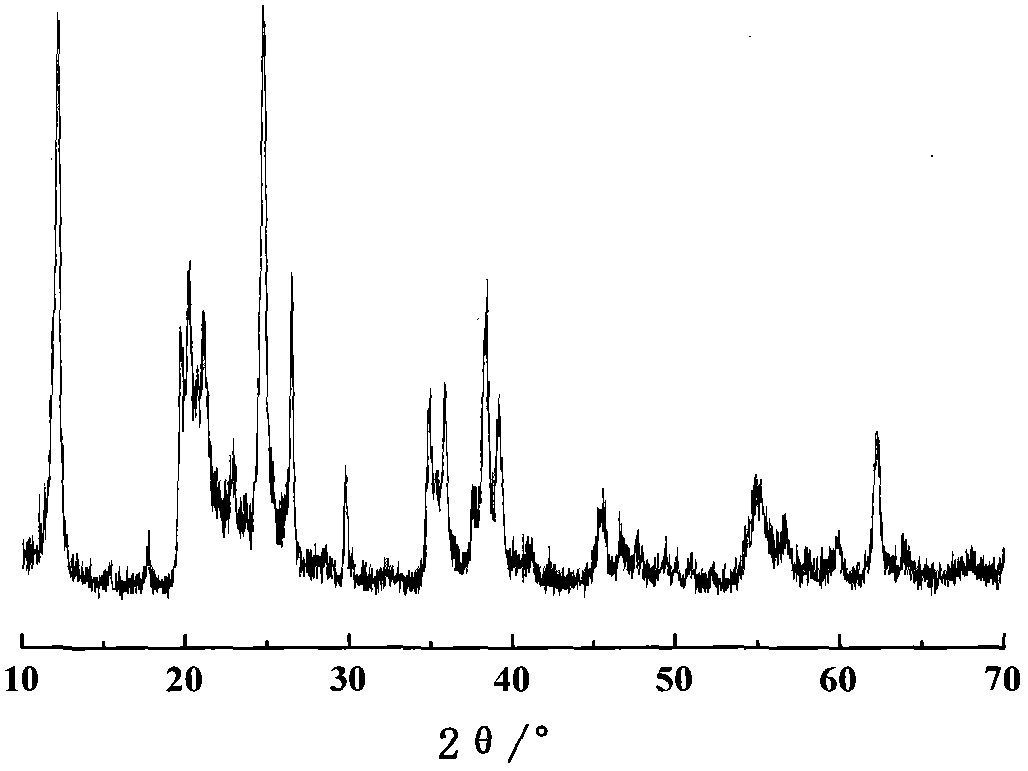

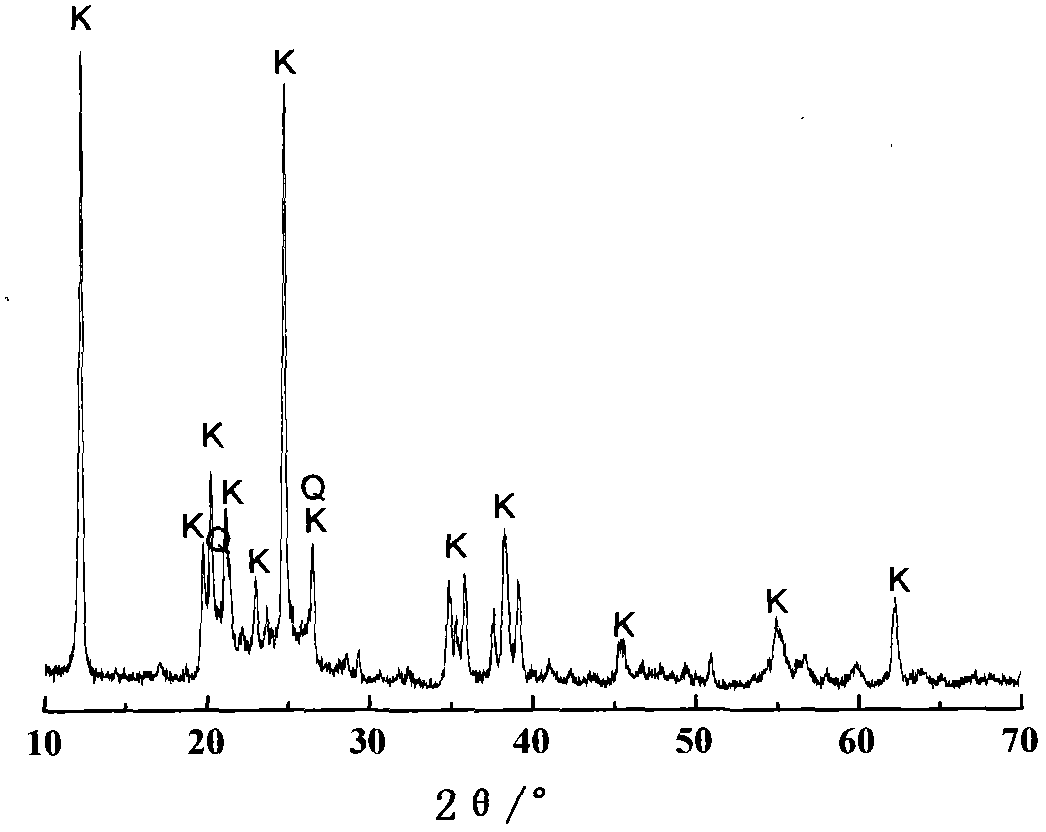

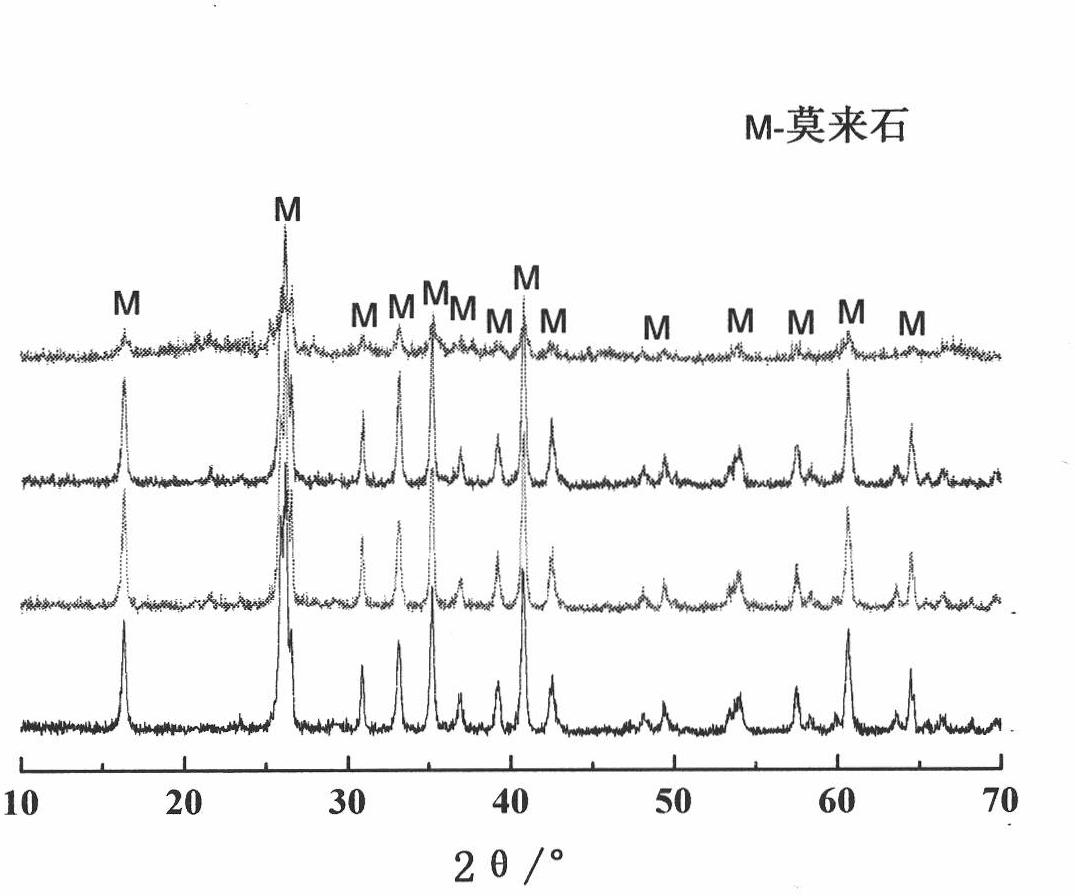

Image

Examples

Embodiment 1

[0035] Activated kaolin: use kaolin as raw material, raise the temperature up to 1000°C at a rate of 10°C / min, then increase to 1400°C at a rate of 5°C / min, keep warm for 2 hours and then cool naturally.

[0036] Take 10 g of activated kaolin as a benchmark, take 16 g of NaOH and 100 mL of distilled water; put the activated kaolin into a beaker equipped with NaOH solution, and stir with a glass rod; the beaker is sealed and placed on a magnetic heating stirrer to stir and heat up; When the temperature rises to 100°C, move the beaker to a water bath at 100°C for a constant temperature hydrothermal reaction; take out the beaker after 4 hours, fully wash the powder in the beaker until it is neutral, vacuum filter and store at 105°C Nano mullite powder can be obtained after complete drying.

Embodiment 2

[0038] Activated kaolin: use kaolin as raw material, raise the temperature up to 1000°C at a rate of 10°C / min, then increase to 1400°C at a rate of 5°C / min, keep warm for 2 hours and then cool naturally.

[0039]Taking 10 g of activated kaolin as a benchmark, take 12 g of NaOH and 100 mL of distilled water; put the activated kaolin into a beaker equipped with NaOH solution and stir with a glass rod; the beaker is sealed and placed on a magnetic heating stirrer to stir and heat up; When the temperature rises to 80°C, move the beaker to a water bath at 80°C for constant temperature hydrothermal reaction; take out the beaker after 5 hours, fully wash the powder in the beaker until it is neutral, vacuum filter and dry at 105°C Nano mullite powder can be obtained after complete drying.

Embodiment 3

[0041] Activated kaolin: use kaolin as raw material, raise the temperature up to 1000°C at a rate of 10°C / min, then increase to 1400°C at a rate of 5°C / min, keep warm for 2 hours and then cool naturally.

[0042] Take 10 g of activated kaolin as a benchmark, take 16 g of NaOH and 100 mL of distilled water; put the activated kaolin into a beaker equipped with NaOH solution, and stir with a glass rod; the beaker is sealed and placed on a magnetic heating stirrer to stir and heat up; When the temperature rises to 100°C, move the beaker to a water bath at 100°C for a constant temperature hydrothermal reaction; take out the beaker after 3 hours, fully wash the powder in the beaker until it is neutral, vacuum filter and dry at 105°C Nano mullite powder can be obtained after complete drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com