Method for recycling waste ammonia water

A technology for recycling and processing ammonia water, which is used in water/sewage treatment, water/sludge/sewage treatment, and ammonia preparation/separation. Material consumption, the realization of economic and social benefits, the effect of reducing the impact of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

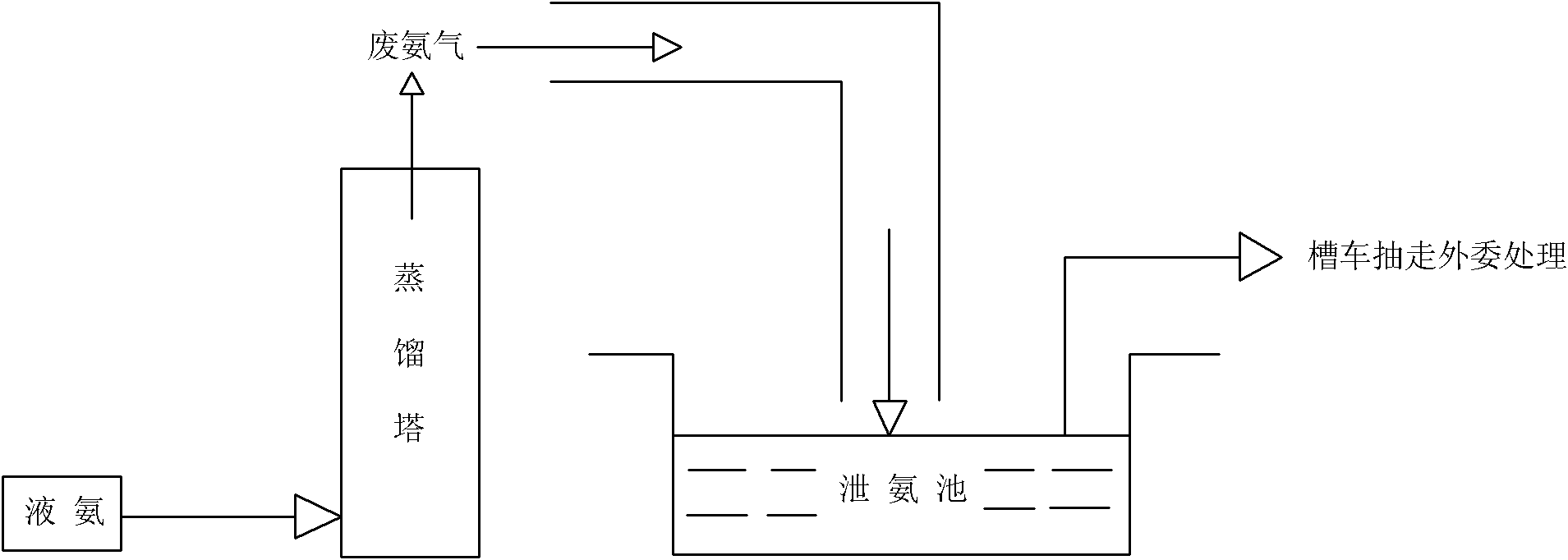

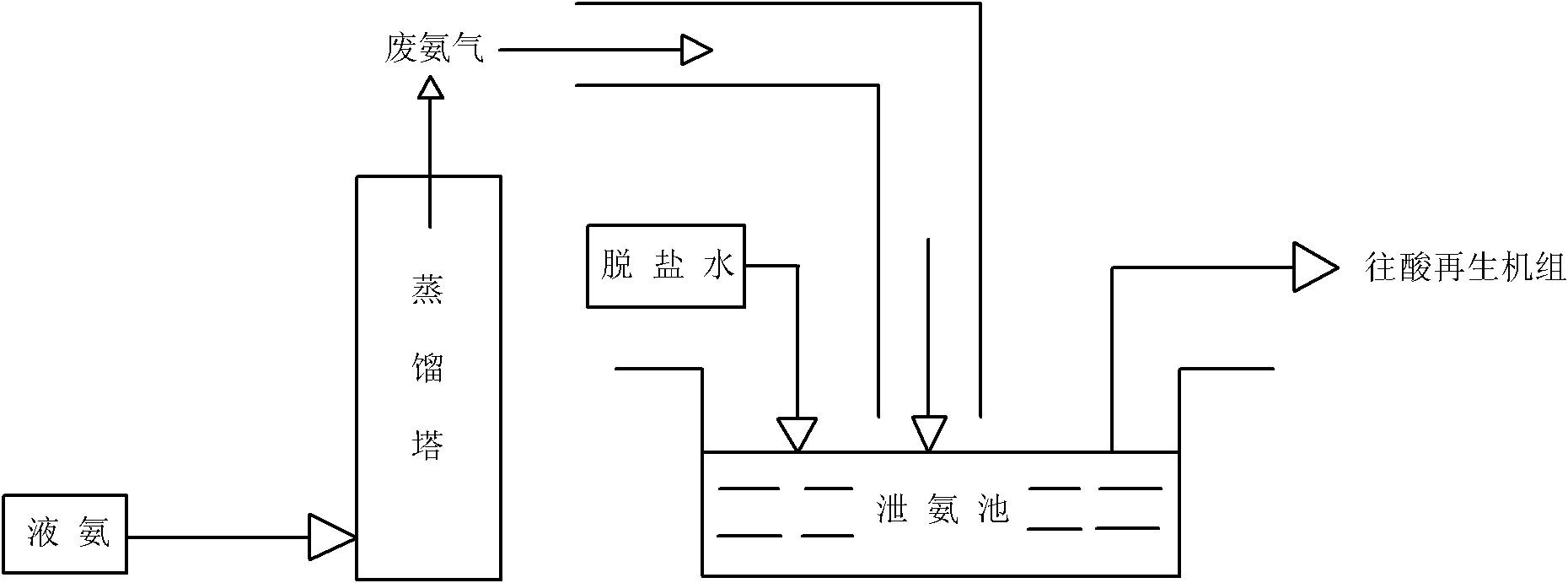

[0030] see figure 2 , image 3 , the waste ammonia recovery process flow of the present invention is as follows:

[0031] 1) Add desalted water or pure water to the ammonia release pool.

[0032] 2) After the ammonia gas is passed into the ammonia release tank, start to sample and test the waste ammonia water in the tank, and continuously add desalted water or pure water to the tank during this process until the concentration of the waste ammonia water is lower than 10wt%. At the same time, the suspended particle content in the waste ammonia water When it drops below 10mg / l, stop adding desalted water or pure water at this time, and use a tank truck to pump out the waste ammonia water for later use.

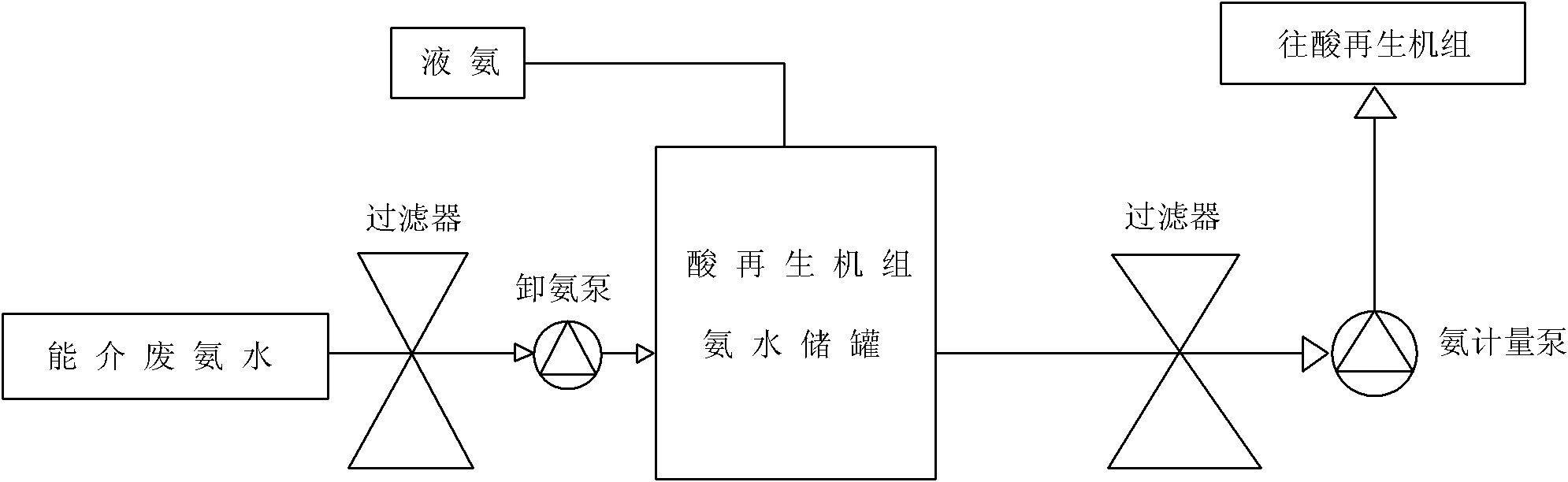

[0033] 3) Add a filter before the ammonia discharge pump of the acid regeneration unit and before the ammonia water metering pump, and the filtration accuracy is required to be less than 100 μm.

[0034] 4) The waste ammonia water is injected into the ammonia water storage ta...

Embodiment 2

[0039] Example 2: Utilize waste ammonia to neutralize and remove silica in waste hydrochloric acid

[0040] 1. Heat waste hydrochloric acid to 70°C and react with a large amount of steel scrap to generate ferrous chloride and hydrogen: 2HCl+Fe=FeCl 2 +H 2 ↑.

[0041] 2, ferrous chloride solution is cooled to 40 DEG C, and wherein the waste ammonia water that process of the present invention is generated is added, and waste ammonia water addition is 0.018wt% (mass percentage) of ferrous chloride amount, generates ferrous hydroxide : FeCl 2 +2NH 3 ·H 2 O=Fe(OH) 2 +2NH 4 Cl.

[0042] 3. Blow compressed air into ferrous hydroxide to oxidize it into ferric hydroxide, which is a sol-like substance, which can capture and precipitate silicon dioxide in waste hydrochloric acid to achieve the effect of desiliconization. The pure ferrous chloride in the upper layer of the solution can be used as the raw material of the acid regeneration unit.

[0043] As a common unit in the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com