Method for recycling chlorine gas from HCl-containing exhaust gas and preparing manganese chloride, and manganese chloride crystals

A technology of tail gas recovery and manganese chloride, which is applied in the direction of manganese halide, etc., can solve the problems of high impurities, high impurity content of hydrochloric acid products, and difficulty in the reduction and purification of high-valent manganese

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

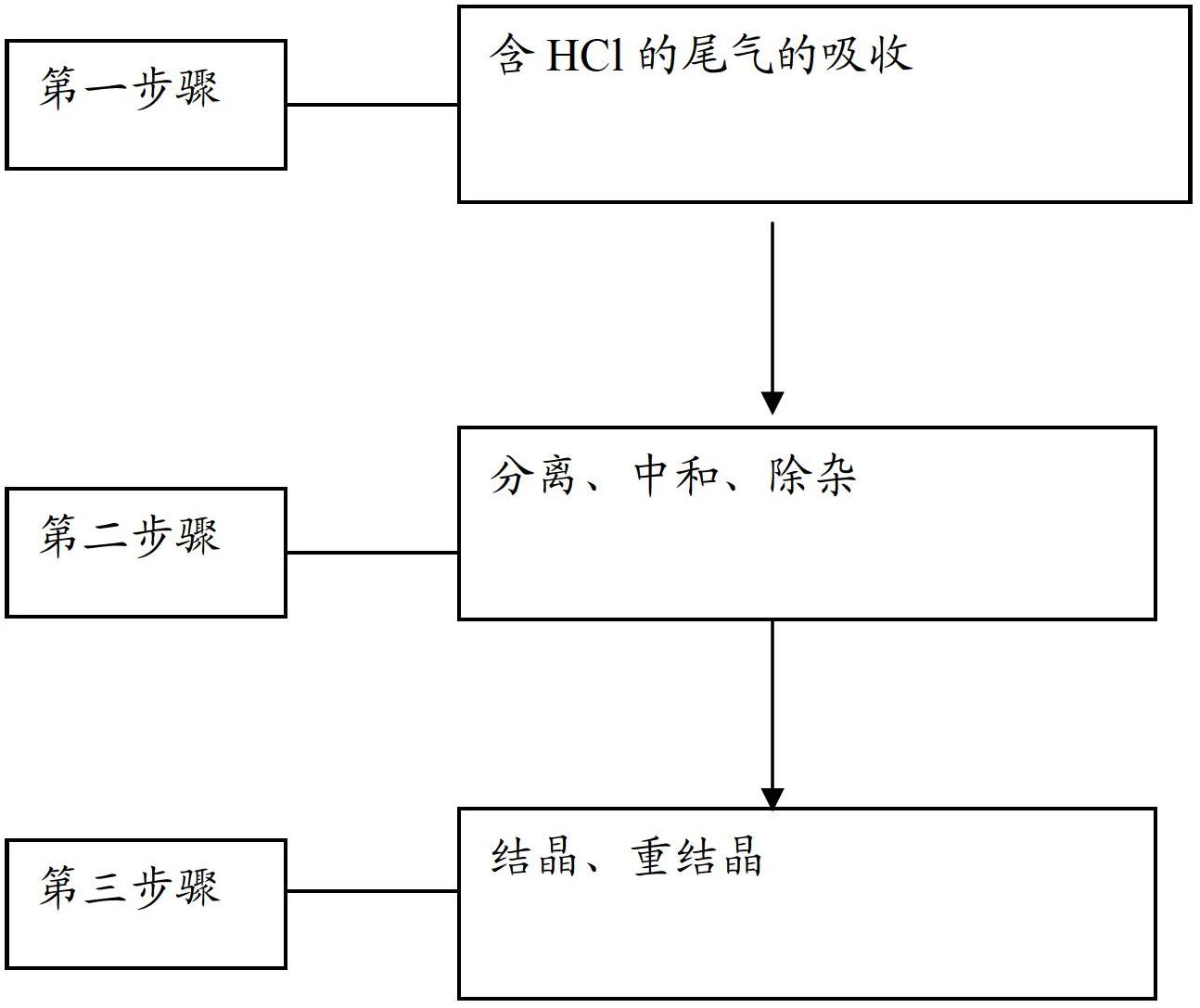

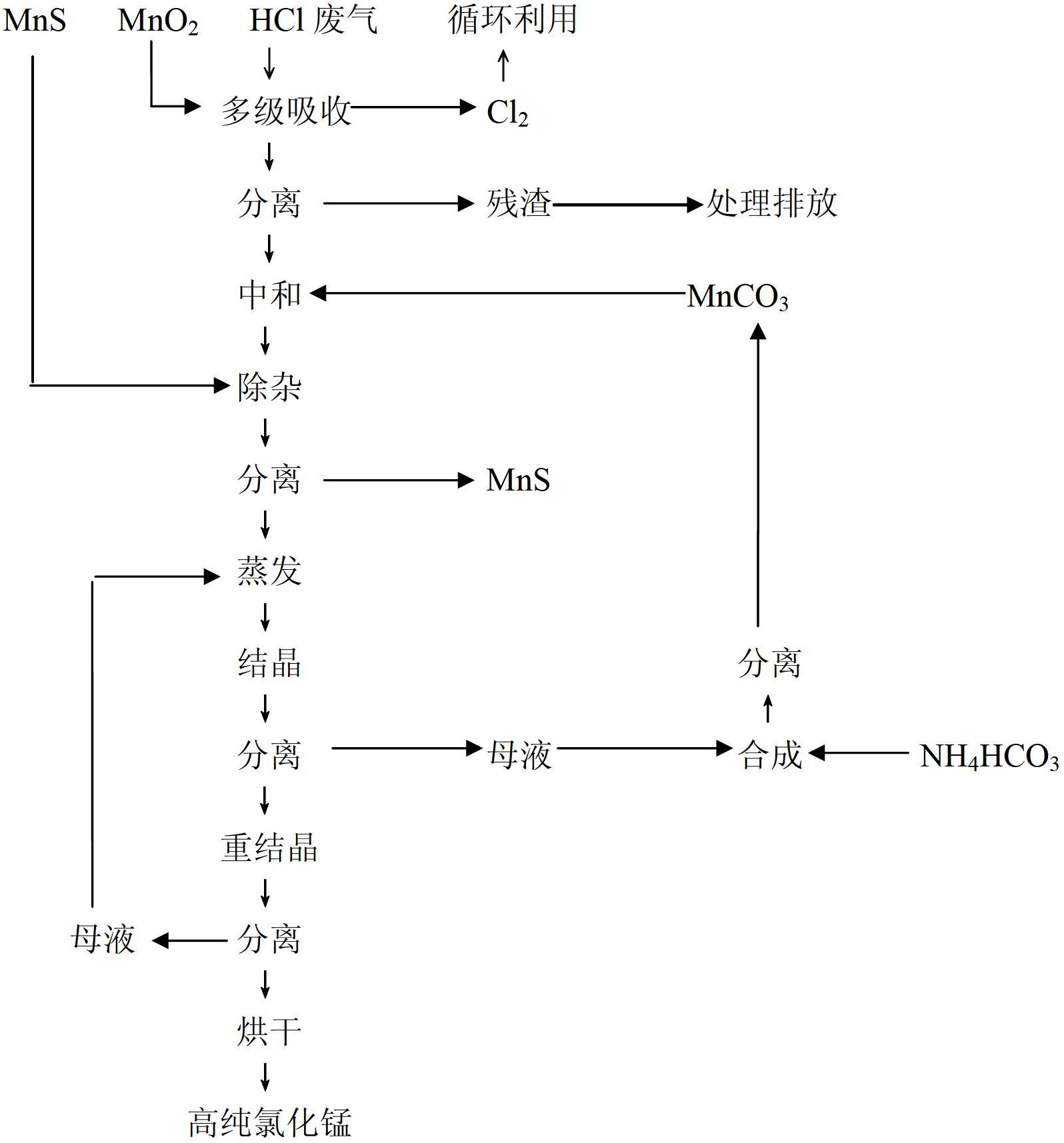

Method used

Image

Examples

Embodiment 1

[0057] Using low-grade MnO with a Mn content of 16.23wt% 2 Mineral powder is used as raw material, and it is formulated to have a solid content of 350Kg / m 3 of slurry. The tail gas containing HCl emitted in the production of sponge titanium is used as raw material. The tail gas mainly includes 14.71% (v / v) chlorine and hydrogen chloride, of which chlorine is about 3-4% (v / v).

[0058] In this embodiment, a three-stage absorption device is used, and the vent is sealed by water sealing with lime solution. Present embodiment process is as follows.

[0059] 1. Absorption of tail gas containing HCl

[0060] First pass the above-mentioned tail gas containing HCl into the first-stage circulation tank of the absorption device, and the average flue gas flow rate is 24000-27000Nm 3 / h, the gas-liquid volume ratio is controlled at 12L / Nm 3 . Then turn on the circulation pump, the above MnO 2 The slurry is pumped to the first, second and third circulation tanks of the absorption un...

Embodiment 2

[0069] Using medium-grade MnO with a Mn content of 24.04wt% 2 Mineral powder is used as raw material, and it is formulated to have a solid content of 300Kg / m 3 of slurry. The HCl-containing tail gas discharged from the sponge titanium industry is used as the raw material. The tail gas mainly includes 17.11% (v / v) chlorine and hydrogen chloride, of which chlorine is about 3-4% (v / v).

[0070] In this embodiment, a three-stage absorption device is used, and the vent is sealed by water sealing with lime solution. Present embodiment process is as follows.

[0071] 1. Absorption of tail gas containing HCl

[0072] First pass the above-mentioned tail gas containing HCl into the first-stage circulation tank of the absorption device, and the average flue gas flow rate is 24000-27000Nm 3 / h, the gas-liquid volume ratio is controlled at 13.5L / Nm 3 . Then turn on the circulation pump, the above MnO 2 The slurry is pumped to the first, second and third circulation tanks of the abso...

Embodiment 3

[0081] Using high-grade MnO with a Mn content of 41.45wt% 2 Mineral powder is used as raw material, and it is formulated to have a solid content of 300Kg / m 3 of slurry. The tail gas containing HCl discharged from the sponge titanium industry is used as the raw material. The tail gas mainly includes 24.17% (v / v) chlorine and hydrogen chloride, of which chlorine is about 3-4% (v / v).

[0082] In this embodiment, a three-stage absorption device is used, and the vent is sealed by water sealing with lime solution. Present embodiment process is as follows.

[0083] 1. Absorption of tail gas containing HCl

[0084] In this embodiment, a three-stage absorption device is used, and the vent is sealed by water sealing with lime solution. First pass the above-mentioned tail gas containing HCl into the first-stage circulation tank of the absorption device, and the average flue gas flow rate is 24000-27000Nm 3 / h, the gas-liquid volume ratio is controlled at 15L / Nm 3 . Then turn on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com