Copper recovery apparatus and copper recovery method

A recovery device and technology of copper hydroxide, applied in separation methods, separation devices, chemical instruments and methods, etc., can solve the problems of a lot of waste, low copper recovery efficiency, low copper purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

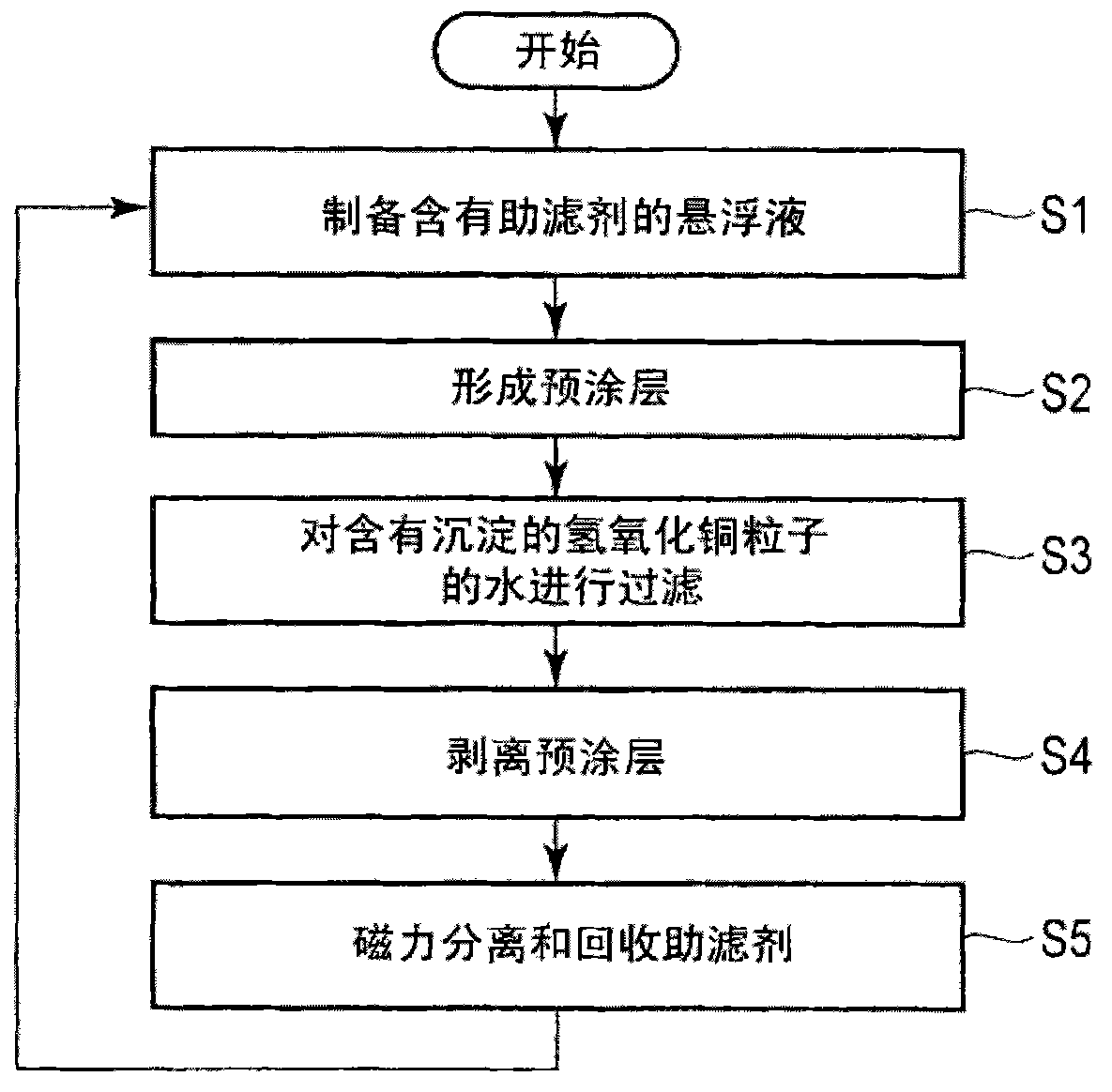

Method used

Image

Examples

no. 3 approach

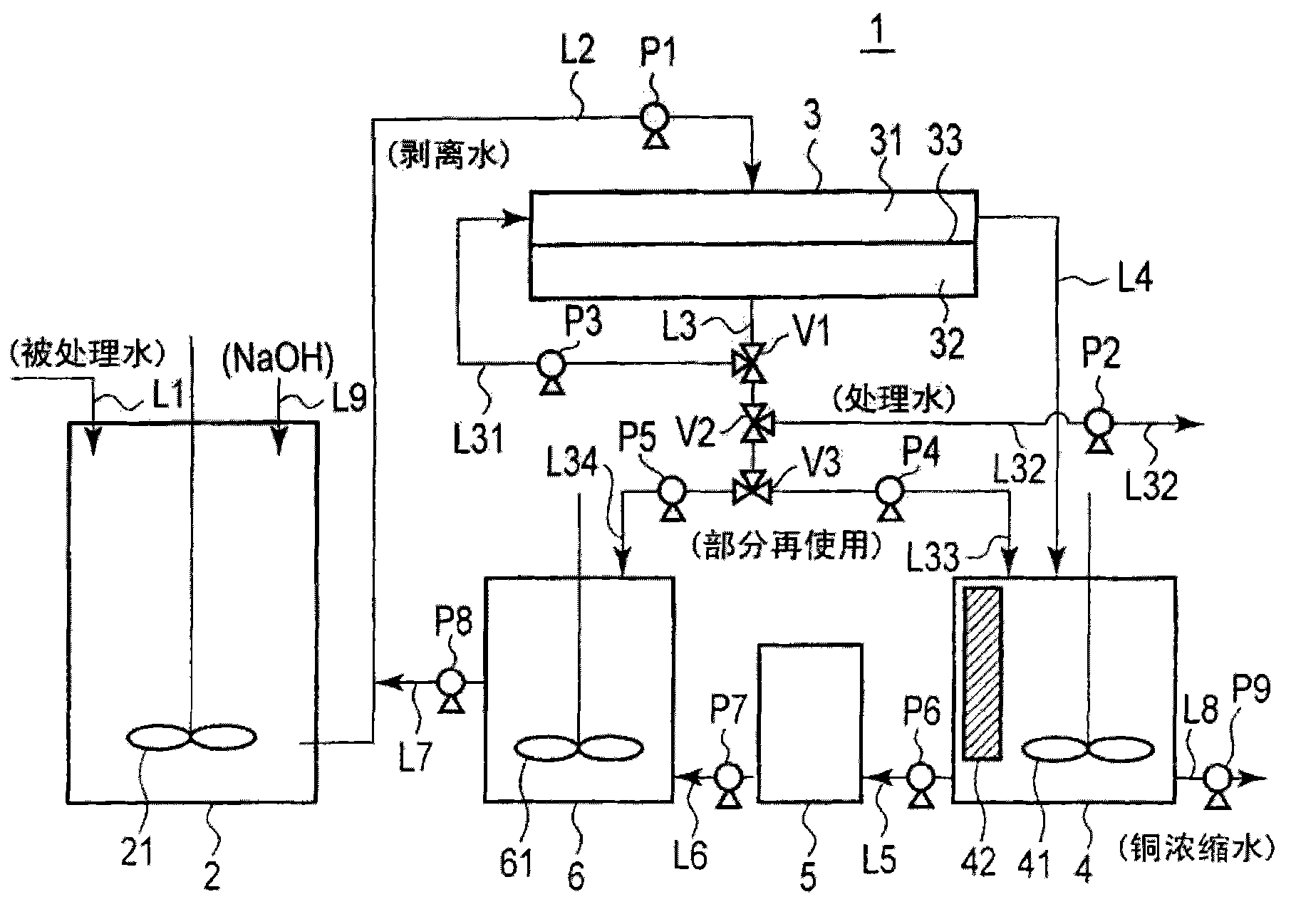

[0099] refer to Image 6 The 3rd copper recovery apparatus 1B used for the precoating method is demonstrated. In addition, this embodiment omits the description of the part which overlaps with the above-mentioned embodiment.

[0100] In the copper recovery device 1B of the third embodiment, the cleaning water supply line L10 and the stripping water supply line L11 , which are two lines for supplying tap water, are respectively connected to the upper space 31 of the solid-liquid separator 3B. The cleaning water supply line L10 is connected to the upper space 31 of the solid-liquid separator 3B, supplies tap water to the upper space 31 , and removes ionic components in the copper compound contained in the deposit layer on the filter 33 . By introducing abundant tap water into the upper space 31 of the solid-liquid separator through the cleaning water supply line L10, cationic components (Na ions, Ca ions, Mg ions, etc.) contained in the precoat layer can be effectively removed....

Embodiment 1

[0119] made as figure 1 Apparatus 1 shown roughly. Water to be treated containing copper is supplied to the precipitation tank 2, and an aqueous sodium hydroxide solution (indicated as NaOH in the figure) is added to the precipitation tank to make it alkaline and copper hydroxide is deposited. In addition, the filter aid is sent from the filter aid tank 5 to the mixing tank 6, and is mixed with a part of the reused treated water to prepare a filter aid slurry. First, the filter aid slurry is sent to the upper space 31 of the solid-liquid separation device 3 to form a filter aid film on the filter 33 . Thereafter, the liquid to be treated obtained by precipitating copper is supplied under pressure to the solid-liquid separation device 3 , and solid-liquid separation (filtration) is performed by passing through a membrane of a filter aid formed in advance. The filtrate is a weakly alkaline treatment liquid from which copper has been removed, and it can be drained through a neu...

Embodiment 2

[0123] Using the same apparatus as in Example 1, except that the filter aid B was used instead of the filter aid A, the test was carried out in the same manner. The recovery rate of copper is above 99%. Compared with Example 1, the flow rate of the solid-liquid separation device became half, but still operated without problems.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com