Material for manufacturing solid-state energy storage capacitor

An energy storage capacitor, solid-state technology, applied in fixed capacitor parts, fixed capacitor dielectrics, etc., can solve the problems of high thermal dispersion of electrical properties, low reliability, large volume, etc., and achieve the effect of good energy storage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

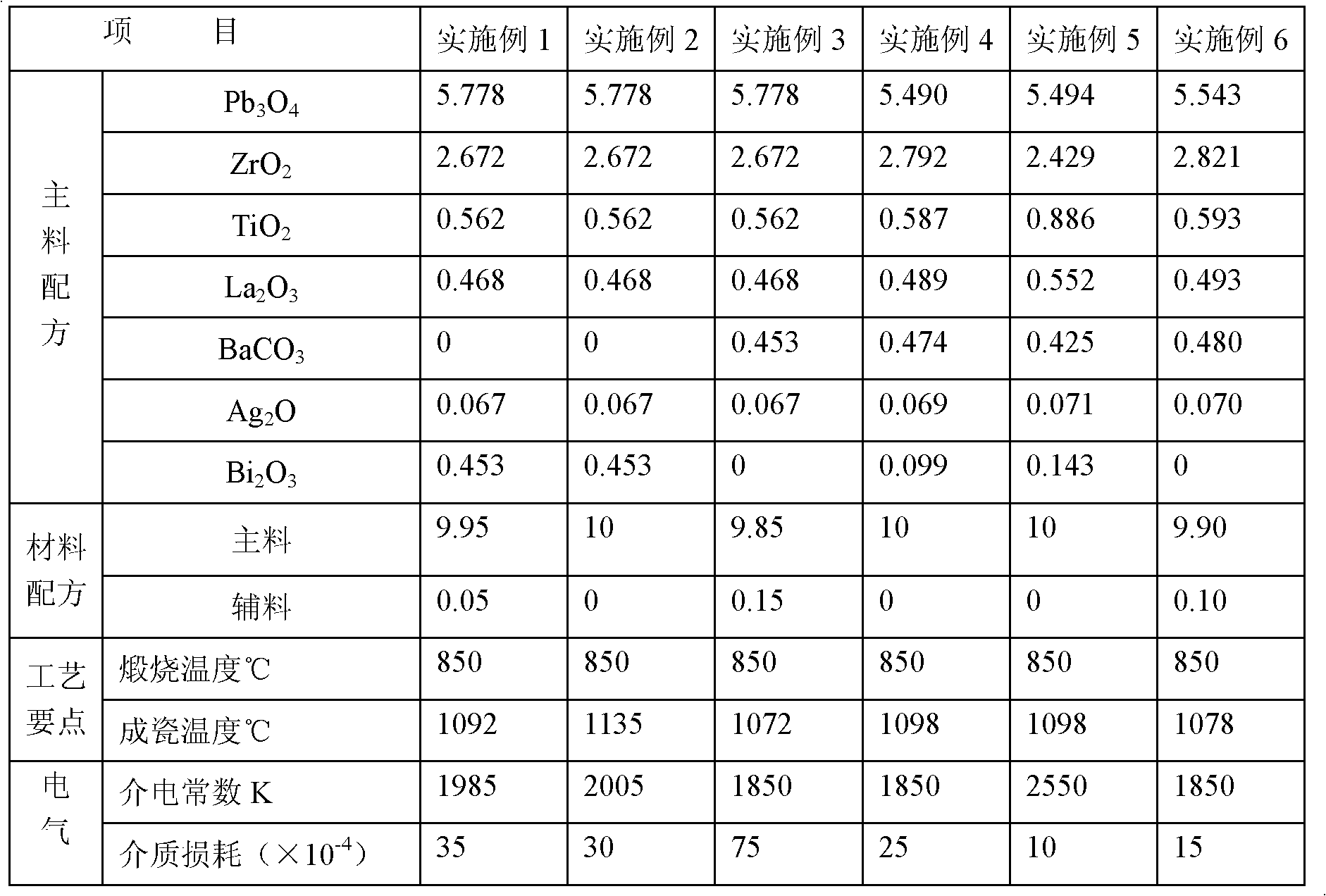

[0038] Main material preparation: get lead oxide, zirconium oxide, titanium oxide, lanthanum oxide, barium carbonate, silver oxide, bismuth oxide to configure 10 kilograms of main material raw materials according to the formula described in table 1, press " batching-abrasive-baking material-calcining (850 ±5℃)-crushing-fine grinding (D 50 ≤2μ)-drying” process route to prepare main materials for use.

[0039] Preparation of auxiliary materials: Take 40 grams of boron oxide, 40 grams of silicon oxide, 10 grams of aluminum oxide, 50 grams of zinc oxide, 370 grams of cadmium oxide, 240 grams of bismuth oxide, and 250 grams of lead oxide to configure 1 kg of auxiliary materials. Drying - calcining (850±5°C) - cold water extraction - fine grinding (D 50 ≤1μ)-drying” process route to prepare auxiliary materials for use.

[0040] Preparation of the present invention: according to the material formula described in Table 1, the main material and auxiliary materials are uniformly mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com