Refractory castable for submerged-arc furnace for smelting ferro-nickel and preparation method of refractory castable

A technology of refractory castables and submerged arc furnaces, which is applied in the field of unshaped refractory materials, can solve problems such as unsatisfactory lining life, and achieve the effects of low construction labor intensity, good fluidity, and excellent nickel-iron corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] By weight ratio, get 5 parts of chromium oxide powder with a particle size less than 0.074mm, 4 parts of iron red powder with a particle size less than 0.074mm, and 10 parts of magnesia-chromium spinel fine powder with a particle size less than 0.074mm. 76 parts of fused magnesia with a particle size of less than 8 mm, 3 parts of calcium aluminate cement fine powder with a particle size of less than 0.088 mm, 2 parts of silica micropowder with a particle size of less than 5 microns, 0.18 parts of sodium hexametaphosphate and 0.2 parts The sodium citrate is fully mixed evenly to obtain the finished product.

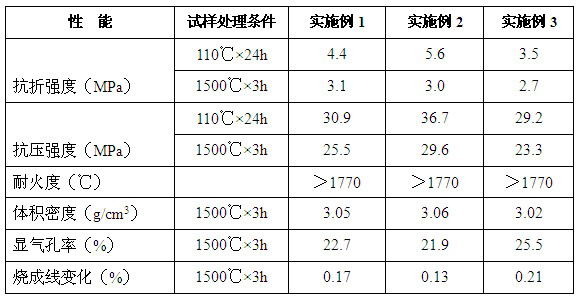

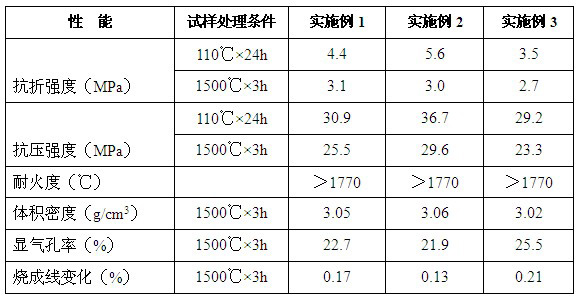

[0017] Take the finished product to make a sample, and test its performance, see the attached table.

Embodiment 2

[0019] According to the weight ratio, get 6 parts of chromium oxide powder with a particle size less than 0.074mm, 4 parts of iron red powder with a particle size less than 0.074mm, and 12 parts of magnesia-chromium spinel fine powder with a particle size less than 0.074mm. 73 parts of fused magnesia with a particle size of less than 8 mm, 3 parts of calcium aluminate cement fine powder with a particle size of less than 0.088 mm, 2 parts of silica fine powder with a particle size of less than 5 microns, 0.18 parts of sodium hexametaphosphate and 0.2 parts The sodium citrate is fully mixed evenly to obtain the finished product.

[0020] Take the finished product to make a sample, and test its performance, see the attached table.

Embodiment 3

[0022] By weight, get 4 parts of chromium oxide powder with a particle size less than 0.074mm, 4 parts of iron red powder with a particle size less than 0.074mm, and 9 parts of magnesia-chrome spinel fine powder with a particle size less than 0.074mm. 80 parts of fused magnesia with a particle size of less than 8 mm, 2 parts of calcium aluminate cement fine powder with a particle size of less than 0.088 mm, 1 part of silica fine powder with a particle size of less than 5 microns, 0.18 parts of sodium hexametaphosphate and 0.2 parts The sodium citrate is fully mixed evenly to obtain the finished product.

[0023] Get the finished products of three embodiments and make sample, detect its performance and see attached table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com