Recycling methods of normal hexane in silica-based aerogel preparation process

A preparation process, n-hexane technology, applied in the direction of silicon oxide, silicon dioxide, absorption purification/separation, etc., can solve the problems of recovery that have not been reported yet, reduce the cost of normal pressure preparation, increase the utilization rate, and the operation method is simple and easy line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

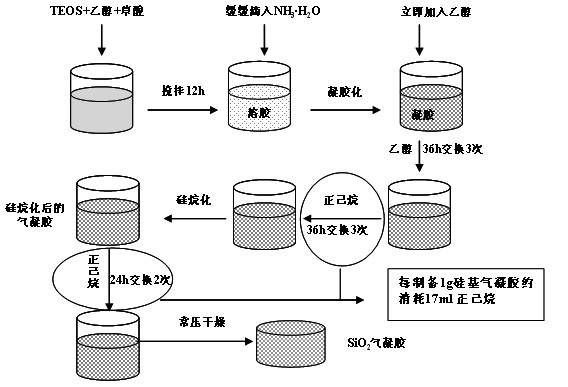

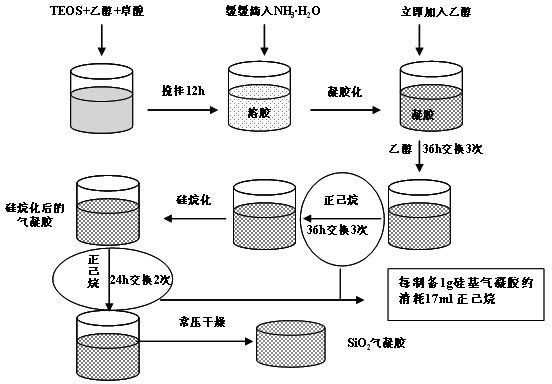

Method used

Image

Examples

Embodiment 1

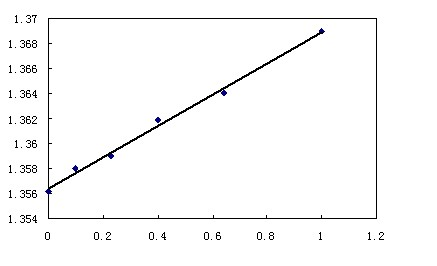

[0022] Embodiment 1 aqueous phase extraction method

[0023] The aqueous phase extraction method uses the principle of the difference in mutual solubility of liquids to separate n-hexane. Ethanol and water are miscible in any ratio, but n-hexane is insoluble in water. Therefore, the aqueous phase extraction method can be used to purify n-hexane. The experimental method is as follows: take 20mL of recovered mother liquor in a beaker, add 20mL of deionized water to it twice, shake and leave it for half an hour, and take the upper layer liquid after liquid separation, namely It is purified n-hexane. The composition and purity of the upper liquid were analyzed by gas chromatography and refractometer. Wherein the analysis condition of gas chromatography is column temperature 34 ℃, detector: 170 ℃, vaporization chamber: 120 ℃, H 2 Flow 30mL / min, air flow 400mL / min, N 2 The flow rate is 25mL / min. Gas phase data show that the purity of n-hexane purified by aqueous phase ...

Embodiment 2

[0024] Embodiment 2 anhydrous calcium chloride method

[0025] The anhydrous calcium chloride method utilizes chemical reactions:

[0026]

[0027] Ethanol can react with anhydrous calcium chloride at room temperature to form a complex, which can exist stably at room temperature, while n-hexane does not react with calcium chloride. The experimental method is as follows: take 3g of anhydrous calcium chloride and add it to 20mL of recovered mother liquor, vibrate, stand still, filter, and collect the filtrate, which is purified n-hexane. The filtrate composition and purity were analyzed by gas chromatography and refractive index. Wherein the analysis condition of gas chromatography is column temperature 34 ℃, detector: 170 ℃, vaporization chamber: 120 ℃, H 2 Flow 30mL / min, air flow 400mL / min, N 2 The flow rate is 25mL / min, and the gas phase data show that the purity of n-hexane purified by anhydrous calcium chloride method reaches 99%, and the refractive index mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com