Homogeneous pectic polysaccharides and method for obtaining same from tea polysaccharides

A technology of pectin polysaccharides and tea polysaccharides, applied in the field of polygalacturonic acid homogeneous pectin polysaccharides, can solve the problems of destroying the active structure of tea polysaccharides, reducing the content of uronic acid, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

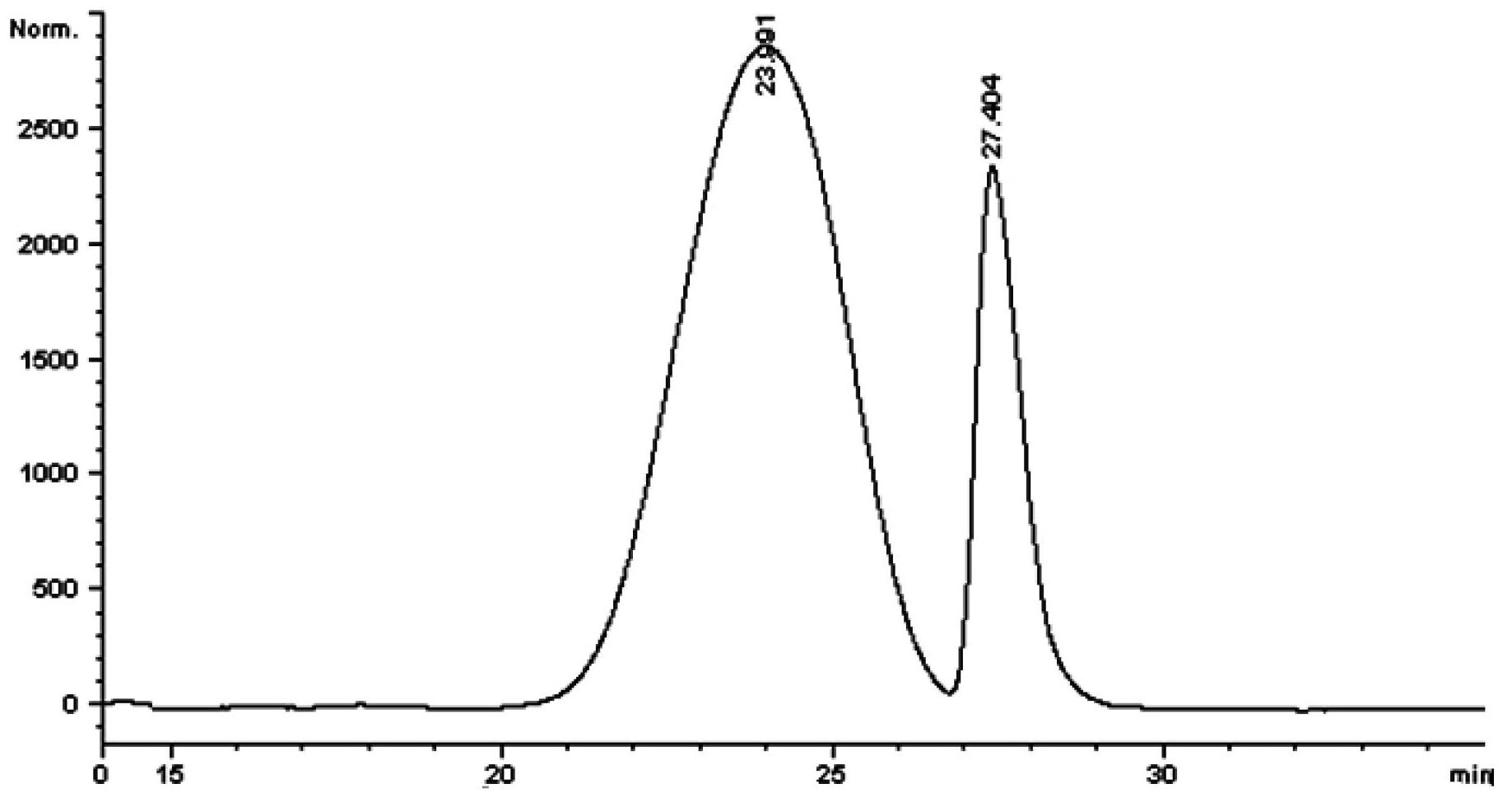

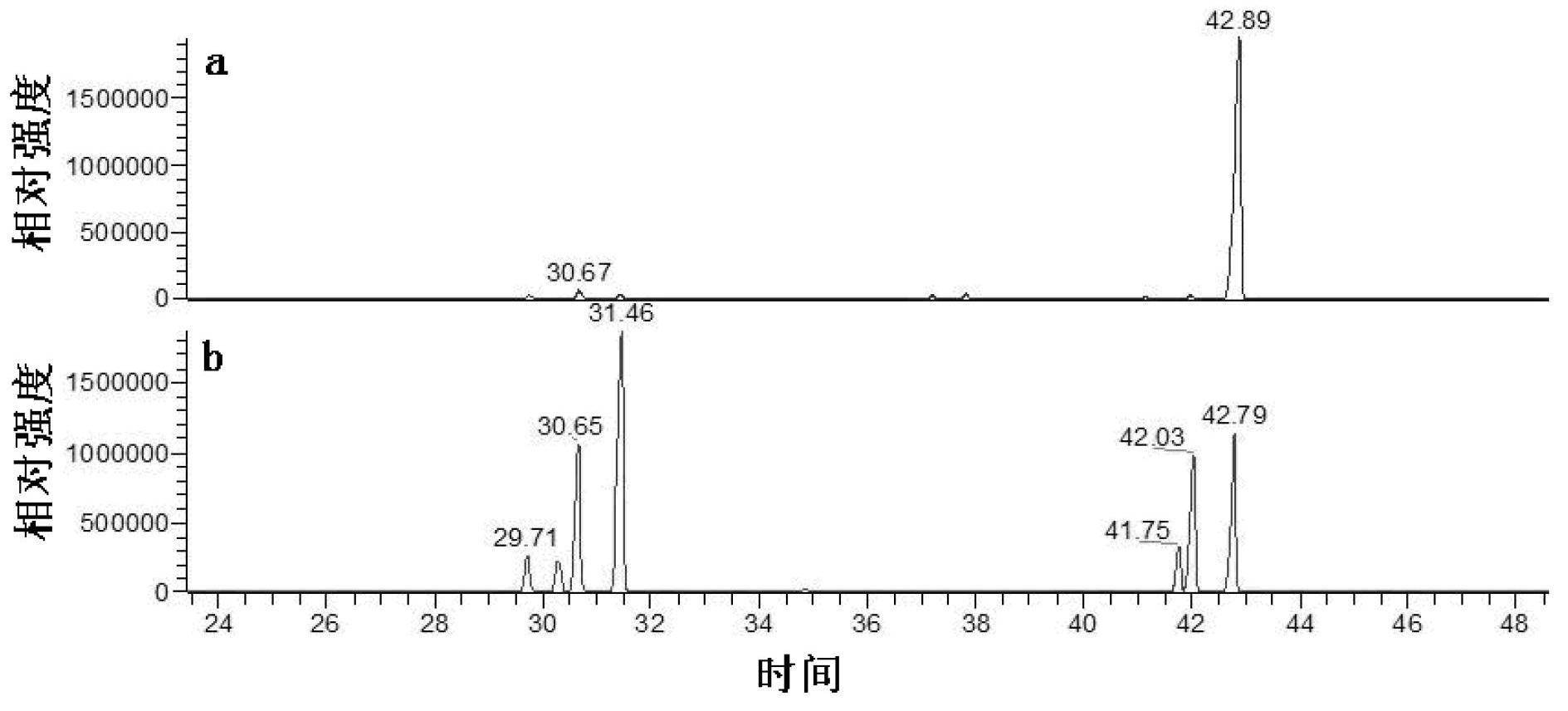

[0104] Embodiment 1: Preparation of uniform pectin polysaccharide TPS4-1B

[0105] 11) Grinding the dried tea leaves to 40-100 meshes;

[0106] 12) Extract twice with water at 100°C. The volume of water added for the first time is 15 times the mass of tea leaves, and the volume of water added for the second time is 10 times the mass of tea leaves; the secondary extracts are combined, concentrated, and ethanol is added for alcohol precipitation to control alcohol The concentration of ethanol in the precipitation system is 40vol%; after alcohol precipitation for 24 hours, filter and collect the precipitate; centrifuge and freeze-dry the precipitate to obtain the crude tea polysaccharide;

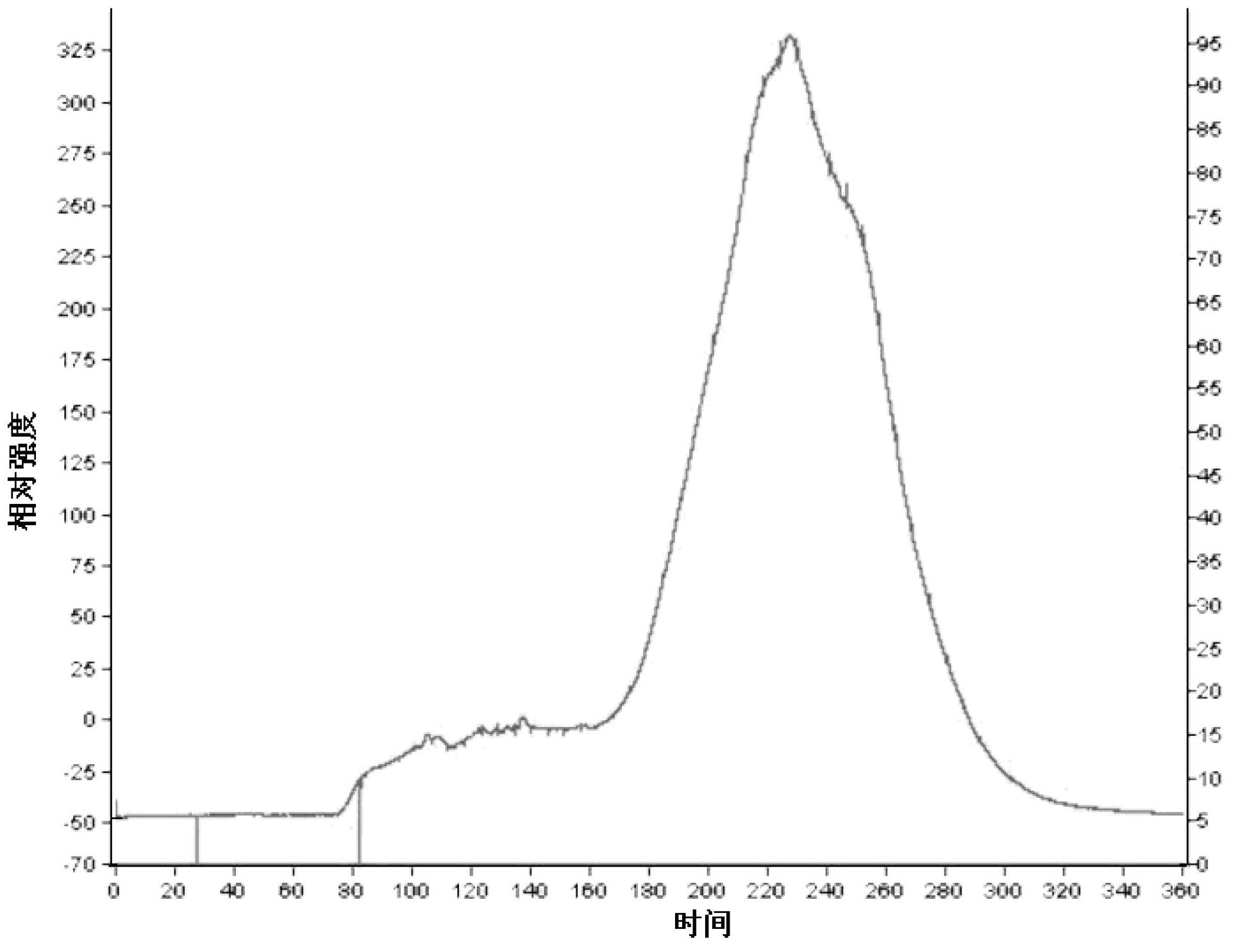

[0107] 13) Put the crude tea polysaccharide obtained in step 12) on the DEAE-Sepharose column, and then elute with water and 0.1mol / L sodium chloride aqueous solution; use the sulfuric acid-phenol method to track the elution curve, collect and utilize 0.1mol / L The effective part that the sodi...

Embodiment 2

[0147] Embodiment 2: Preparation of uniform pectin polysaccharide TPS4-2A

[0148] 21) Grinding the dried tea leaves to 40-100 meshes;

[0149] 22) Extract twice with water at 100°C. The volume of water added for the first time is 15 times the mass of tea leaves, and the volume of water added for the second time is 10 times the mass of tea leaves; the secondary extracts are combined, concentrated, and ethanol is added for alcohol precipitation to control alcohol The concentration of ethanol in the precipitation system is 40vol%; alcohol precipitation? Hours later, filter and collect the precipitate; centrifuge and freeze-dry the precipitate to obtain crude tea polysaccharide;

[0150] 23) Put the crude tea polysaccharide obtained in step 22) on a DEAE-Sepharose column, and then elute with water, 0.1mol / L aqueous sodium chloride solution and 0.2mol / L sodium chloride aqueous solution; use the sulfuric acid-phenol method Track the elution curve, and collect the effective parts ...

Embodiment 3

[0162] Embodiment 3: Preparation of uniform pectin polysaccharide TPS7-1B

[0163] 31) Grinding the dried tea leaves to 40-100 meshes;

[0164] 32) Extract twice with water at 100°C. The volume of water added for the first time is 15 times the mass of tea leaves, and the volume of water added for the second time is 10 times the mass of tea leaves; the secondary extracts are combined, concentrated, and ethanol is added for alcohol precipitation to control alcohol The ethanol concentration in the precipitation system is 70vol%; after 24 hours of alcohol precipitation, filter and collect the precipitate; centrifuge and freeze-dry the precipitate to obtain the crude tea polysaccharide;

[0165] 33) Put the crude tea polysaccharide obtained in step 32) on a DEAE-Sepharose column, and then elute with water and 0.1mol / L sodium chloride aqueous solution; use the sulfuric acid-phenol method to track the elution curve, collect and utilize 0.1mol / L The effective part that the sodium chl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com