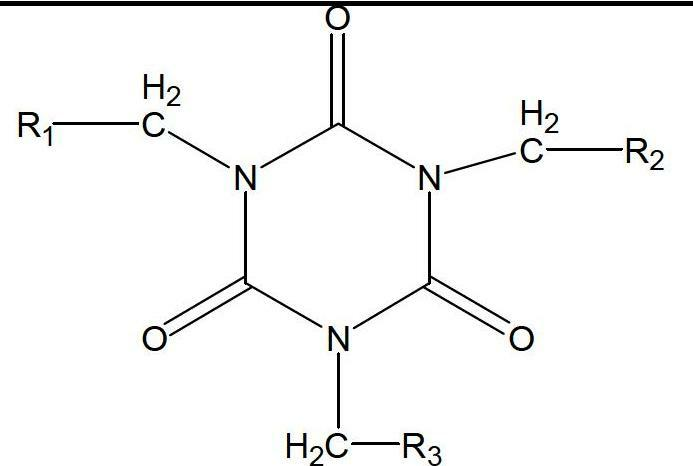

Tripropargyl isocyanuric ester polymer and preparation method thereof

A technology of tripropargyl isocyanurate and propargyl isocyanurate, applied in the field of thermosetting resin and its preparation, can solve the problems of single element, high residual carbon rate, low shrinkage rate, etc. Economical cost, simple process, good effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

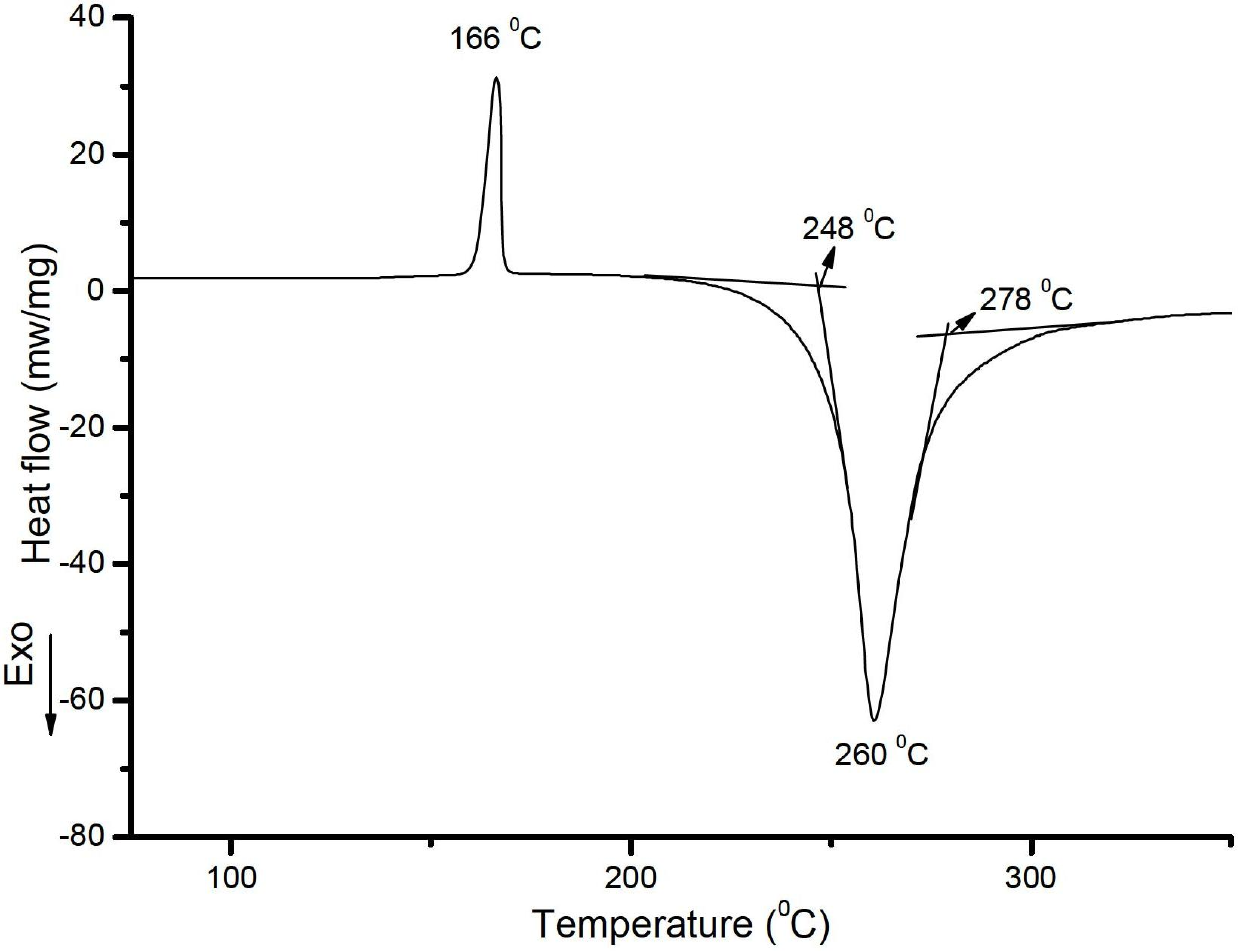

[0027] The prepared tripropargyl isocyanurate monomer (see the patent document with patent number ZL201010533489.0 for the preparation method) is subjected to DSC test, and the DSC curve obtained by the test is shown in figure 2 , figure 2 Among them, 166°C is the melting point temperature, 248°C is the curing start temperature, 260°C is the curing peak temperature, and 278°C is the curing end temperature. Set the melting and solidification temperature accordingly.

Embodiment 2

[0029] Take 243g of the prepared tripropargyl isocyanurate monomer and place it in a porcelain crucible. In a tube furnace under nitrogen protection, the temperature rises to 166°C at a rate of 10°C / min. Hold for 1 hour under temperature conditions, then heat to 248°C at a heating rate of 1°C / min, and keep it at this temperature for 2 hours, then at a heating rate of 1°C / mim to 260°C, and keep it at this temperature 4h, then increase to 278℃ at a rate of 1℃ / min, keep it at this temperature for 1h and then cool to room temperature.

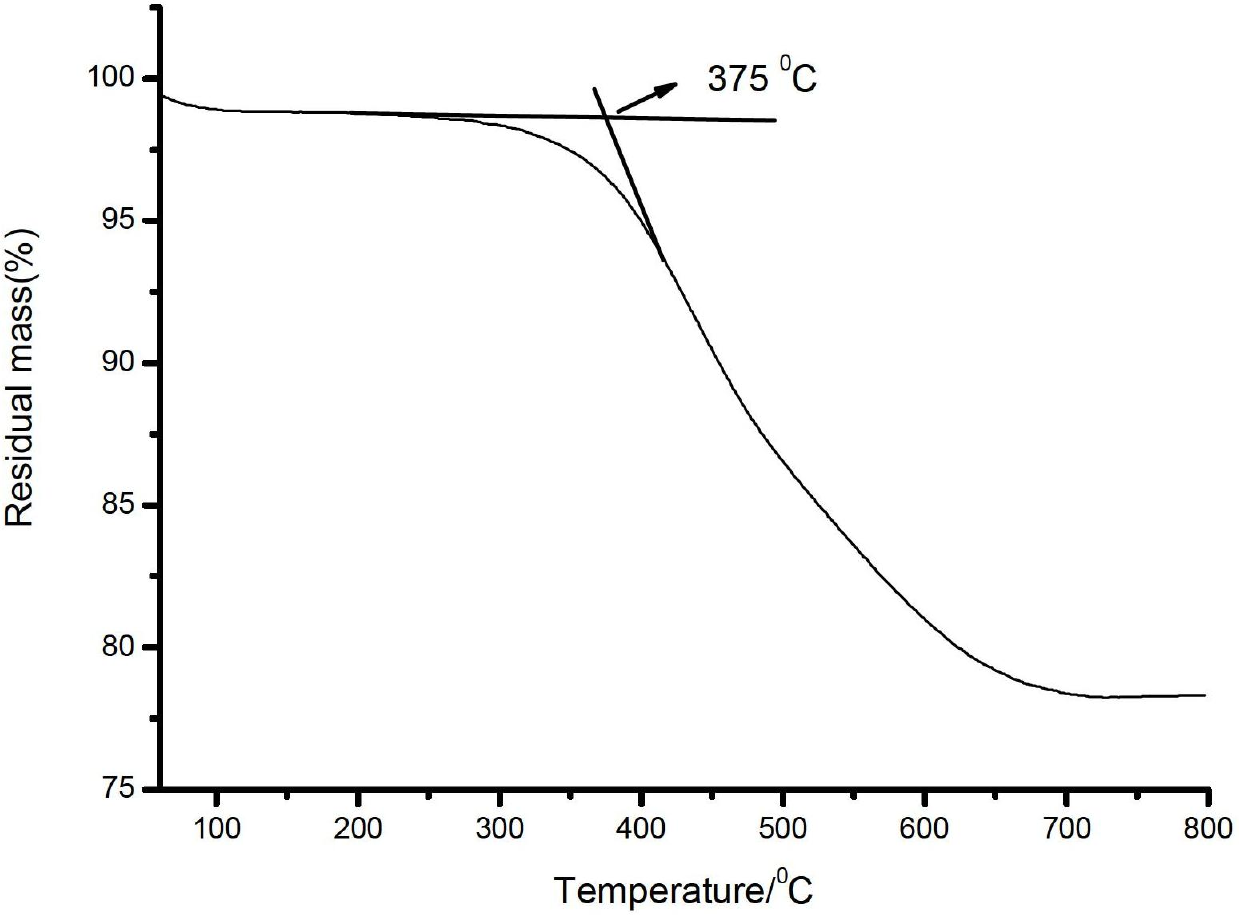

[0030] The cured resin obtained was characterized by TG for its heat resistance: in N 2 Under the atmosphere, the temperature was increased to 800°C at 10°C / min, and the residual mass of the obtained polymer reached 70%.

Embodiment 3

[0032] Take 243g of the prepared tripropargyl isocyanurate monomer and place it in a porcelain crucible. In a tube furnace under the protection of nitrogen, the temperature rises to 168°C at a rate of 15°C / min. Hold for 1 hour under temperature conditions, then heat to 252°C at a heating rate of 1°C / min, and keep it at this temperature for 2 hours, then at a heating rate of 1°C / mim to 266°C, and keep it at this temperature 4h, then increase to 286℃ at a rate of 1℃ / min, keep it at this temperature for 1h and then cool to room temperature.

[0033] The cured resin obtained was characterized by TG for its heat resistance: in N 2 In the atmosphere, the temperature was increased to 800°C at 10°C / min, and the residual mass of the obtained polymer reached 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com