Condensed polytetrafluoroethylene aqueous dispersion, preparation method and application thereof

A technology of polytetrafluoroethylene and water-based dispersion liquid, which is applied in the direction of coating, etc., can solve the problems of inability to balance stability, gloss and coating thickness, etc., achieve gloss improvement, eliminate environmental hazards, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

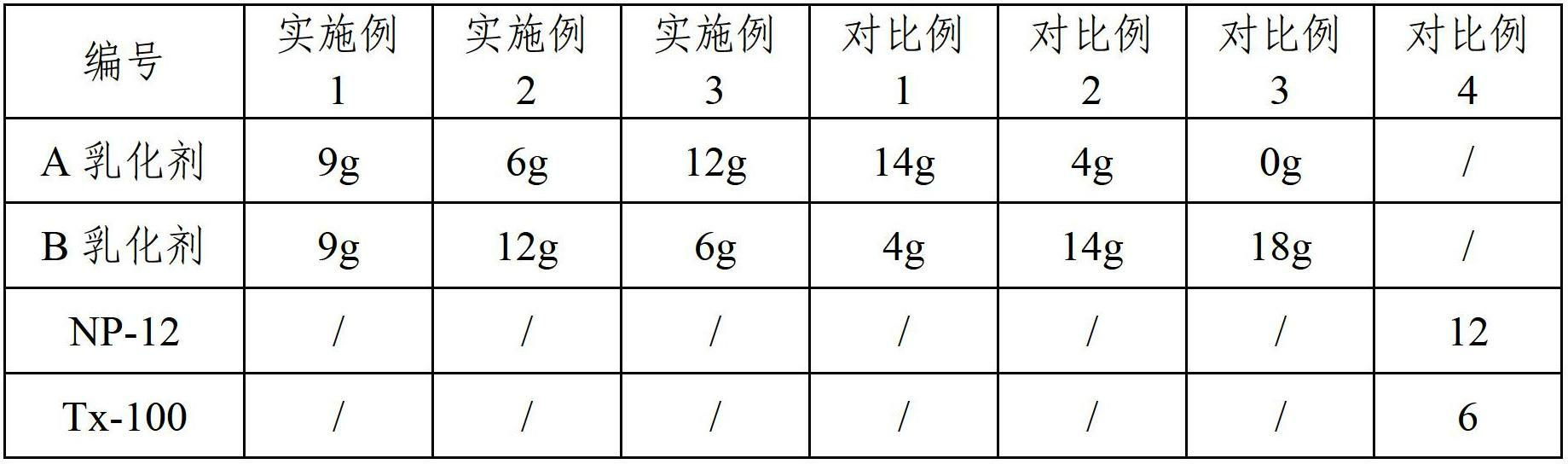

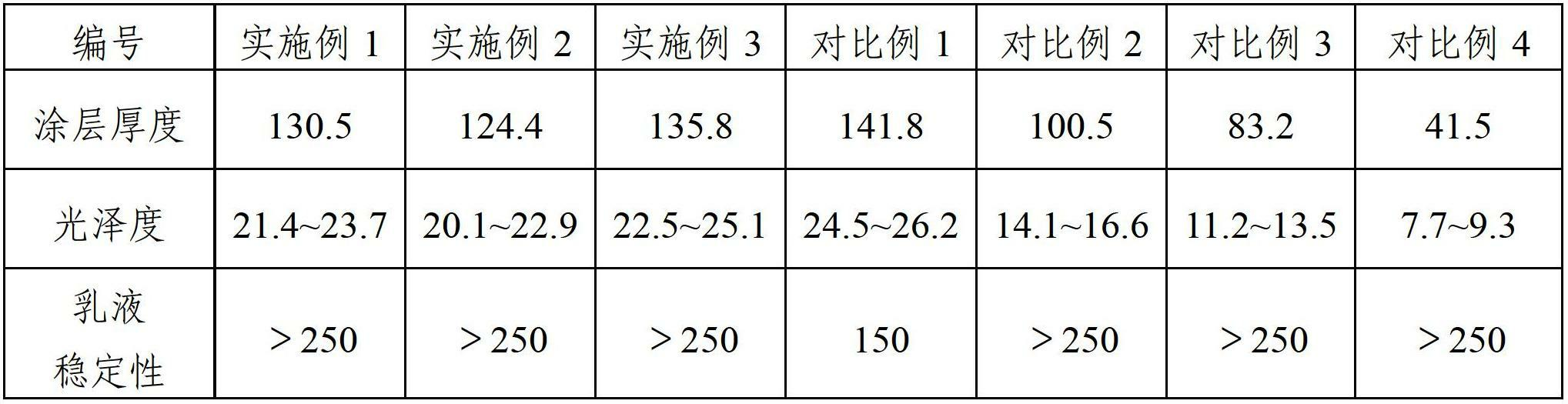

Embodiment 1

[0030] Add 32L of deionized water, 1kg of paraffin, and 8g of ammonium perfluorooctanoate to a 50L reactor with a stirring and cooling jacket. After the reactor is evacuated and replaced with nitrogen three times, the temperature is raised to 70°C, and 0.2g of ammonium persulfate is added to the system. Add tetrafluoroethylene monomer to 2.0MPa to start the reaction. The reaction is carried out for 70 minutes, and the temperature is controlled between 70 and 90°C. After the polymerization is completed, a polytetrafluoroethylene water-dispersed polymer emulsion is obtained. The solid content is about 30wt%, and the average particle size is about 0.19 μm.

[0031]Take 1 kg of the above polytetrafluoroethylene aqueous polymerization solution, add 9g of emulsifier A (the cloud point is 37°C, emulsifier brand 15-S-7, DOW company) and 9g of B emulsifier (the cloud point is 89°C, emulsifier brand 15-S-12, DOW Company) to form a mixed emulsifier, stir and mix well, put the polymerizat...

Embodiment 2

[0034] Get 1kg of polytetrafluoroethylene aqueous polymerization solution in embodiment 1, add 6g A emulsifier (cloud point is 34 ℃, emulsifier brand S-70, Nippon Shokubai company) and 12g B emulsifier (cloud point is 80 ℃, Emulsifier grade AEO-9, Nippon Shokubai company) mixed emulsifier, after stirring and mixing, the polymerization solution is placed in a three-necked round-bottomed flask, and the round-bottomed flask is heated in a water bath, and the external temperature rises to 45 ° C. Evacuate to a vacuum of 0.08MPa, the polymerization liquid in the flask boils, and the water vapor enters the collection bottle through the cooling tube until the polymerization liquid is concentrated to the required concentration, and the concentration process is ended. Then use ammonia water to adjust the pH of the polymerization solution to 8-9 to obtain a concentrated aqueous dispersion.

[0035] The solid content of the obtained aqueous dispersion (based on the total weight of the di...

Embodiment 3

[0037] Get 1kg of polytetrafluoroethylene aqueous polymerization solution prepared in Example 1, add 12g A emulsifier (the cloud point is 37 ℃, emulsifier brand 15-S-7, DOW company) and 6g B emulsifier (the cloud point is 80 ℃ , emulsifier brand AEO-9, Nippon Shokubai company) mixed emulsifier, after stirring and mixing, the polymerization solution is placed in a three-necked round-bottomed flask, and the round-bottomed flask is heated in a water bath, and the external temperature is raised to 60 ° C. After condensation The tube is evacuated to a vacuum of 0.09MPa, the polymerization liquid in the flask is boiling, and the water vapor is cooled by the condenser tube and enters the collection bottle until the polymerization liquid is concentrated to the required concentration, and the concentration process is ended. Then use ammonia water to adjust the pH of the polymerization solution to 8-9 to obtain a concentrated aqueous dispersion.

[0038] The solid content of the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com