Liquid crystal aligning agent, liquid crystal aligning film and liquid crystal display element

A technology of liquid crystal aligning agent and group, which is applied in liquid crystal materials, instruments, optics, etc. It can solve the problems of unrecorded voltage retention rate and image sticking characteristics, and achieve excellent uniform coating, high-speed response voltage retention rate, and light resistance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0140]

[0141] As mentioned above, although this liquid crystal aligning agent contains [A] polymer as an essential component, and can contain other optional components as needed, it is preferable to prepare as the composition of the solution form which each component melt|dissolved in the organic solvent.

[0142] As the organic solvent that can be used to prepare the liquid crystal aligning agent, an organic solvent that dissolves the [A] polymer and other optional components and does not react with them is preferred. As an organic solvent, the organic solvent etc. which were illustrated above as being used for synthesis|combination of the said polyamic acid are mentioned, for example. Moreover, the poor solvent illustrated as a poor solvent used for the synthesis|combination of a polyamic acid can also be used together. Moreover, these organic solvents may be used individually or in combination of 2 or more types.

[0143] The preferred solvent that can be used to prepa...

Embodiment

[0157] Hereafter, although an Example demonstrates this invention more concretely, this invention is not limited to these Examples.

[0158] The weight average molecular weight (Mw) of [A] polymer obtained in the following Example is a polystyrene conversion value measured by the GPC of the following standard.

[0159] Column: Tosoh Corporation, TSKgelGRCXLII

[0160] Solvent: THF

[0161] Temperature: 40°C

[0162] Pressure: 68kgf / cm 2

Synthetic example 1

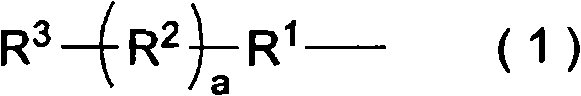

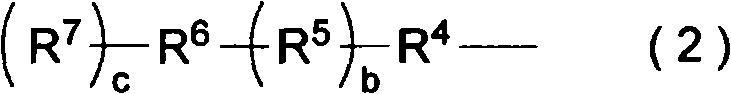

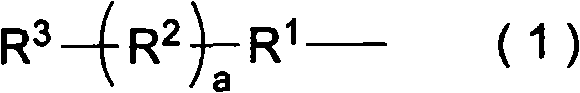

[0164] Compounds 1, 2 and 3 were synthesized according to the following reaction scheme.

[0165]

[0166] Add 12.6 g (0.0645 mol) of 4-cyano-4'-hydroxybiphenyl, 17.0 g (0.0717 mol) of 10-bromo-1-decanol, 28.4 g of potassium carbonate and 350 mL of N,N-dimethylformamide was heated and stirred at 160° C. for 5 hours. After confirming the completion of the reaction by TLC, the reaction solution was cooled to room temperature. The reaction solution was poured into 1000 mL of water, and mixed and stirred. The precipitated white solid was separated by filtration and further washed with water. The obtained solid was vacuum-dried at 80° C. to obtain 20.6 g of the above-mentioned compound 1 . Next, 20 g (0.0569 mol) of the obtained compound 1 was dissolved in 150 mL of dehydrated tetrahydrofuran (THF), 7.49 g (0.0740 mol) of triethylamine was added, and then slowly added by dissolving in 150 mL of THF under ice-cooling for 30 minutes. 14.4 g (0.0625 mol) of the obtained 3,5-din...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com