Lubricating oil additive as well as preparation method and application thereof

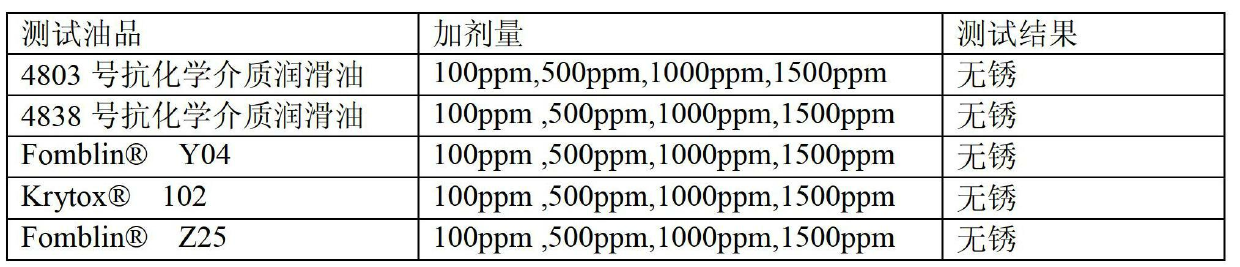

A lubricating oil additive and lubricating oil technology, applied in additives, lubricating compositions, petroleum industry, etc., can solve the problems of fluorine-containing lubricating oil application limitations, inability to dissolve well, and inability to achieve anti-rust effects, etc. Anti-rust operation effect, increase operation effect and service life, and anti-rust performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

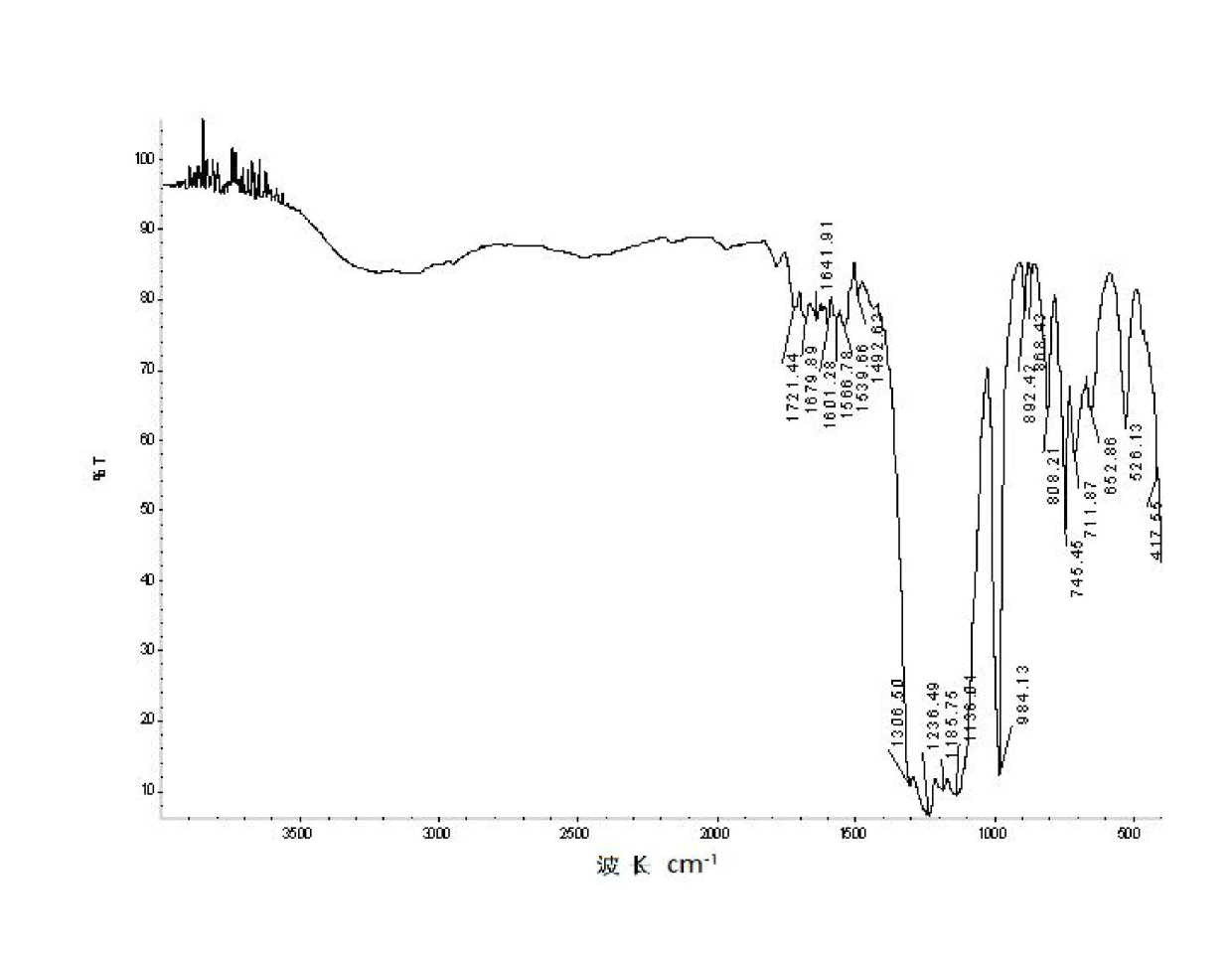

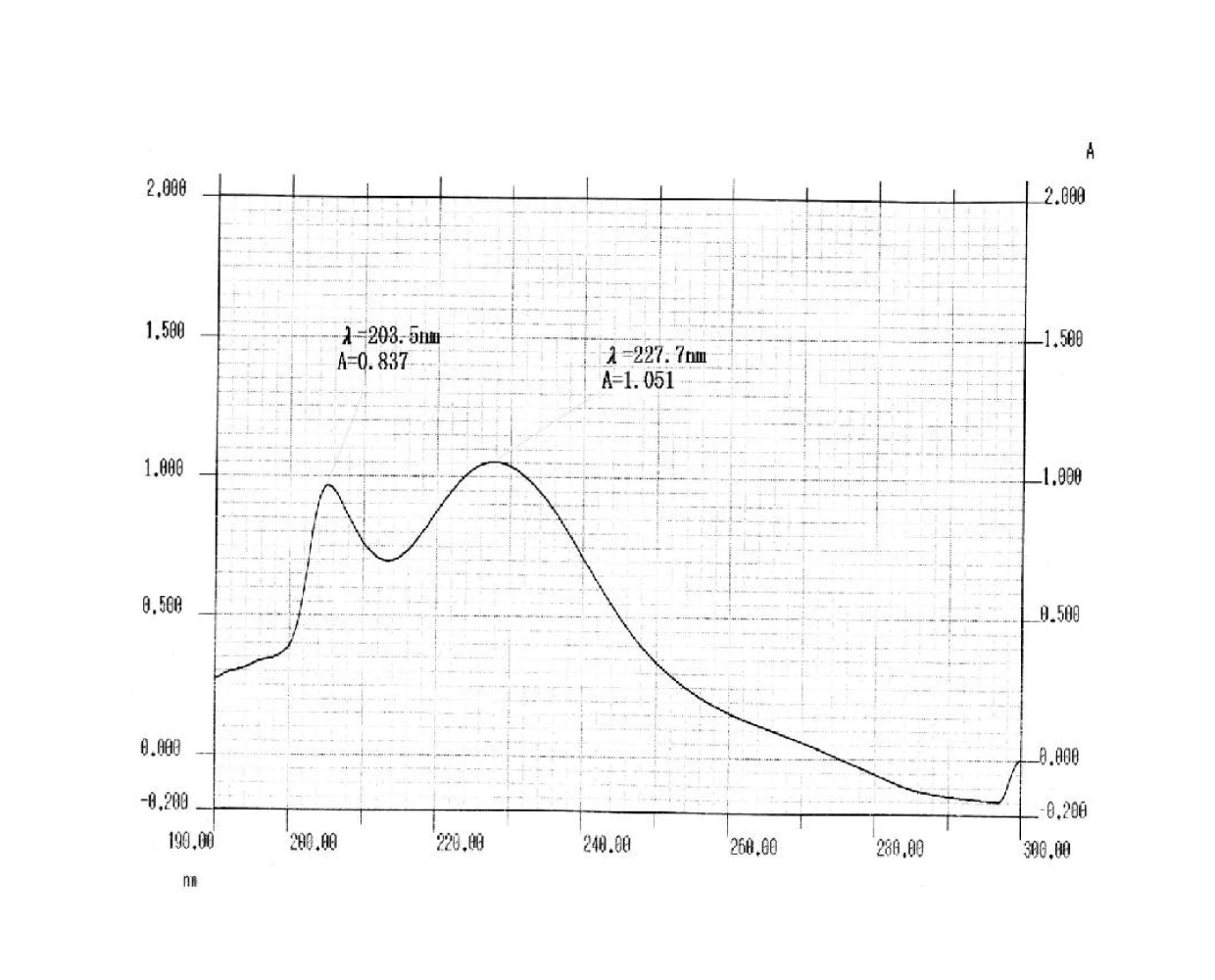

[0035] (1) Preparation of perfluoropolyetheryl fluoride

[0036] Add hexafluoropropylene into the photooxidation reactor at a rate of 0.1kg / h, and oxygen at a rate of 100L / h, cool down the mixed hexafluoropropylene and oxygen to -70°C, and then turn on the ultraviolet lamp to irradiate and perform photooxidation. The reaction is initiated to obtain perfluoropolyetheryl fluoride as shown in formula (II).

[0037] (2) Separation of perfluoropolyether fluoride

[0038] Take 5kg of perfluoropolyetheryl fluoride prepared in step (1) and add it to the still, turn on the vacuum pump, keep the pressure of the distillation system at 40±5mmHg, heat up, and collect the distillate at 200°C to 250°C for later use. The obtained perfluoropolyetheryl fluoride The etheroyl fluoride fraction has a molecular weight of 3200 to 4800.

[0039] (3) Preparation of imidazoline intermediates

[0040] Add 500ml of solvent xylene, 1000g of benzoic acid and 800g of diethylenetriamine to a 3L reactor, p...

Embodiment 2

[0047] (1) Preparation of perfluoropolyetheryl fluoride

[0048] Add hexafluoropropylene into the photooxidation reactor at a rate of 1kg / h, and oxygen at a rate of 550L / h, cool down the mixed hexafluoropropylene and oxygen to -50°C, and then turn on the ultraviolet lamp for photoinitiation reaction to obtain perfluoropolyetheryl fluoride as shown in formula (II).

[0049] (2) Separation of perfluoropolyether fluoride

[0050] With embodiment 1.

[0051] (3) Preparation of imidazoline intermediates

[0052] Add solvent xylene 3L, benzoic acid 3110g and diethylenetriamine 1300g to a 10L reactor, pass nitrogen protection, stirring speed 50r / min, heat up to 100°C, stop stirring and heating after reacting for 5h, cool to room temperature, and then remove the solvent xylene by distillation to obtain the imidazoline intermediate as shown in formula (Ⅲ).

[0053] (4) Preparation of lubricating oil additives

[0054] Take 100g of the imidazoline intermediate obtained in step (3) ...

Embodiment 3

[0059] (1) Preparation of perfluoropolyetheryl fluoride

[0060] Add hexafluoropropylene into the photooxidation reactor at a rate of 5kg / h, add oxygen at a rate of 3500L / h, cool down the mixed hexafluoropropylene and oxygen to -40°C, and then turn on the ultraviolet lamp for photoinitiation reaction to obtain perfluoropolyetheryl fluoride as shown in formula (II).

[0061] (2) Separation of perfluoropolyether fluoride

[0062] With embodiment 1.

[0063] (3) Preparation of imidazoline intermediates

[0064] Add solvent xylene 10L, benzoic acid 6700g and diethylenetriamine 11200g to a 50L reactor, pass nitrogen protection, stirring speed 50r / min, heat up to 160°C, stop stirring and heating after reacting for 12h, cool to room temperature, and then remove the solvent xylene by distillation to obtain the imidazoline intermediate as shown in formula (Ⅲ).

[0065] (4) Preparation of lubricating oil additives

[0066] Take 4Kg of the imidazoline intermediate obtained in step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com