Deinking device and method for waste paper magnetic-separation deinking machine

A deinking machine and magnetic separation technology, applied in the processing of waste paper, chemical instruments and methods, papermaking, etc., can solve the problems of difficult washing or flotation, poor deinking effect, difficult treatment, etc. The effect of increasing the deinking concentration and improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

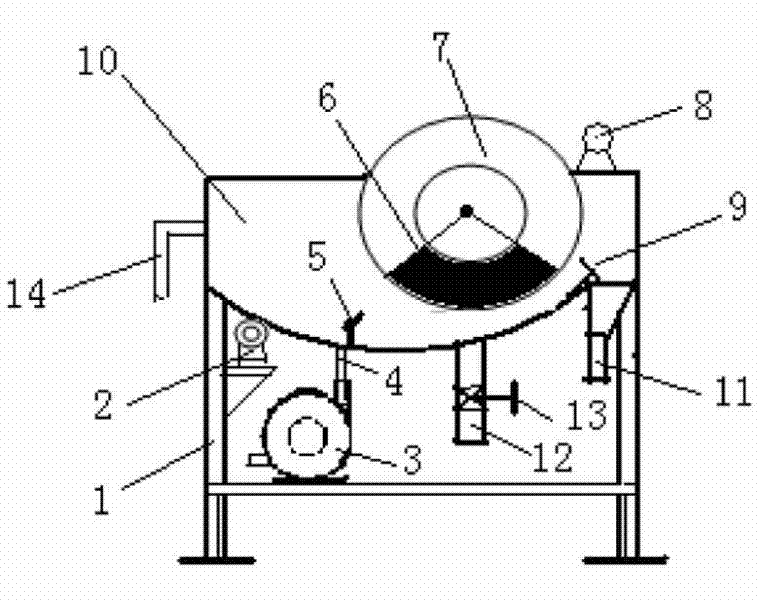

[0036] Example 1: Office waste paper with a whiteness of 89% ISO is prepared into a slurry with a concentration of 3-4w%. After being treated by this device, high-grade cultural paper with a whiteness of 95% can be obtained with a fiber loss of 5%.

Embodiment 2

[0037] Example 2: Waste magazine paper with a brightness of 73% ISO is prepared into a slurry with a concentration of 3-4w%. After being treated by this device, cultural paper with a brightness of 89% can be obtained, and the fiber loss is 7%.

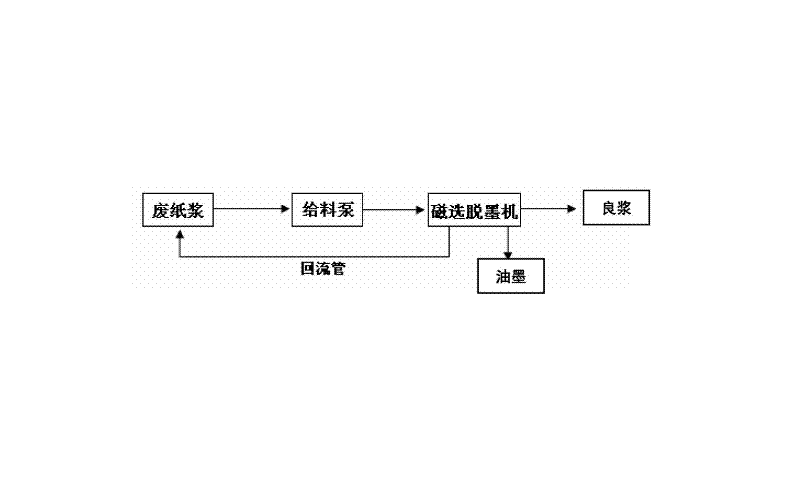

[0038] The waste paper magnetic separation deinking device and deinking method of the present invention, the pulp is fed into the pulp from the bottom pressure, the dispersion degree of the pulp is improved, the entrainment of the magnetic substance to the paper fiber is reduced, and the magnetic substance (ink) is easily adsorbed on the magnetic drum , thus improving the deinking rate and fiber yield. It can be magnetically separated with a higher pulp concentration, which improves the processing capacity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com