Method for measuring time delay by synchronous signal trigger sweep

A technology of synchronization signal and delay time, which is applied in the field of delay time measurement of synchronization signal-triggered scanning method, can solve problems such as the deviation of the starting point of exposure and absolute graphic position, and achieve the effect of solving absolute positioning accuracy and improving absolute positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

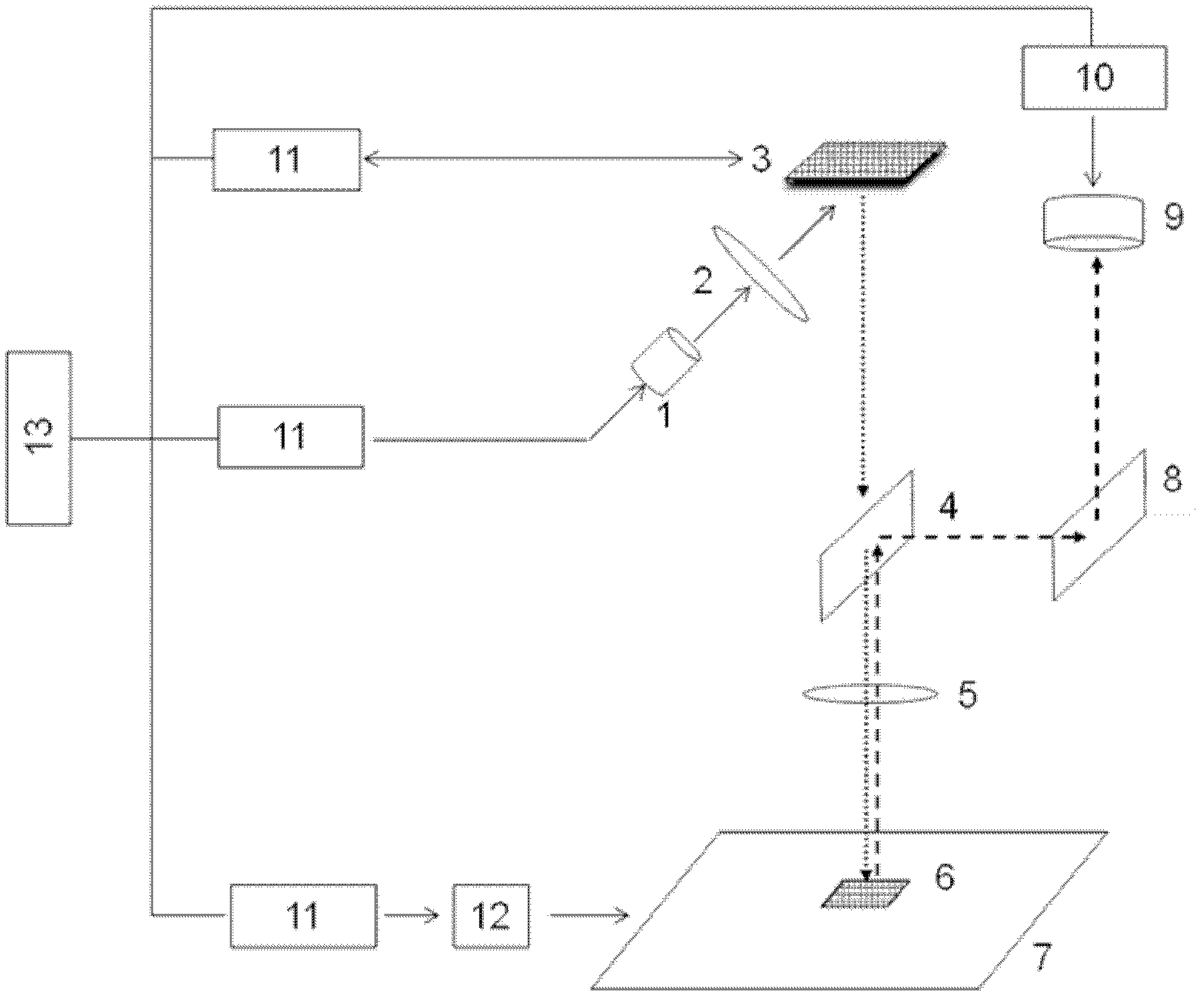

[0023] like Figure 1-4 As shown, the method for measuring the delay time of the scanning mode triggered by a synchronous signal includes a projection exposure module and a main control module. The projection exposure module includes an exposure light source 1 and a spatial light modulator 3. There is an optical light collection system 2, an inclined beam splitter 4 is arranged under the spatial light modulator 3, a base 6 is arranged under the beam splitter 5, and a lens (group) 5 is also arranged between the beam splitter 4 and the base 6, A reflector 8 is provided on the front optical path of the splitting surface of the beam splitter 4, a CCD camera 9 is arranged on the front optical path of the reflected light of the reflector 8, and the substrate 6 is placed on the precision mobile platform 7; the main control module includes a computer system 13. The controller 11 and the computer system 13 are respectively controlled and connected to the spatial light modulator 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com