Shell-type transformer with improved heat dissipation performance

A technology for shell-type transformers and heat dissipation performance, which is applied in the directions of transformer/inductor cooling, transformer/inductor core, transformer/inductor coil/winding/connection, etc., which can solve the complex process of high-voltage winding layout, increase loss and heat , Insufficient insulation strength and other problems, to achieve the effect of reducing the uneven distribution of temperature, reducing resistance, and low end temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in detail below, and the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following embodiments.

[0024] The problem to be solved in this embodiment is to find a non-forced heat dissipation method with simple structure and process, small size and light weight, which can effectively reduce the maximum temperature of the inner core column and winding of the thin and tall shell type amorphous alloy transformer. Lift.

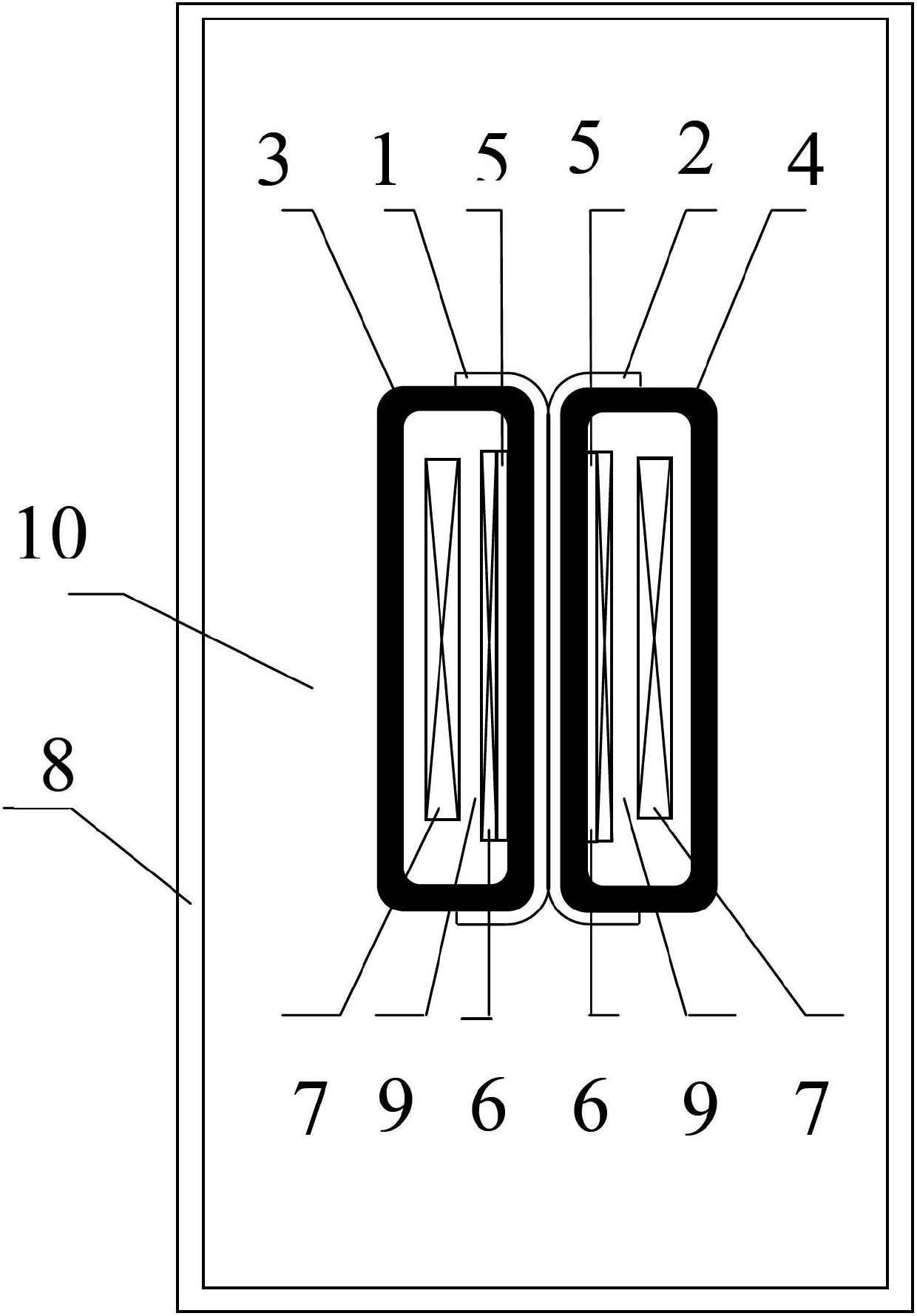

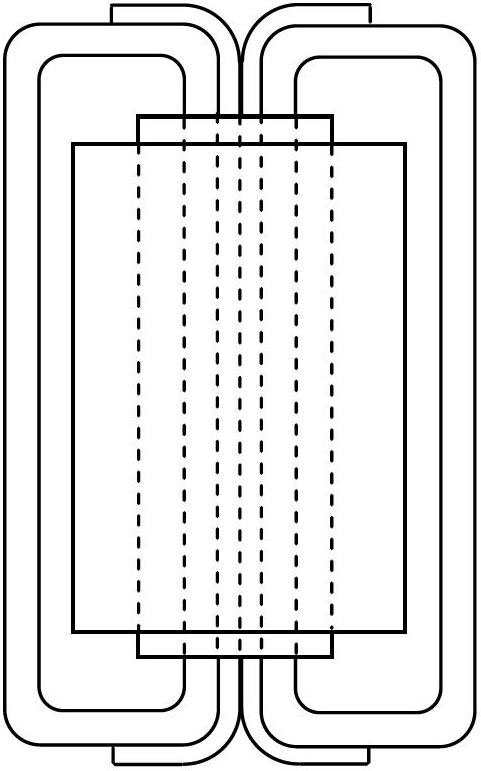

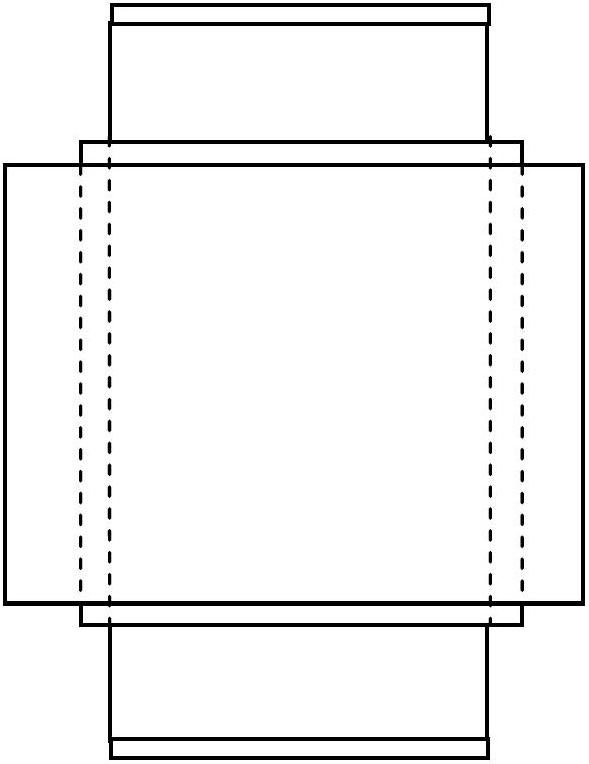

[0025] In this embodiment, the high-voltage winding of the medium-frequency amorphous alloy transformer is 50 kV, and the modular composite shell structure is adopted, which significantly reduces the height of the iron core and yoke, thereby reducing the unevenness of the magnetic field inside the iron core. Moreo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com