Ultrathin high-frequency magnetic core transformer and production process thereof

A high-frequency transformer and production process technology, applied in the field of transformers, can solve the problems of poor quality consistency, high noise and high cost of C-type transformers, and achieve the effects of not easy to scatter, strong corrosion resistance, and good environmental performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

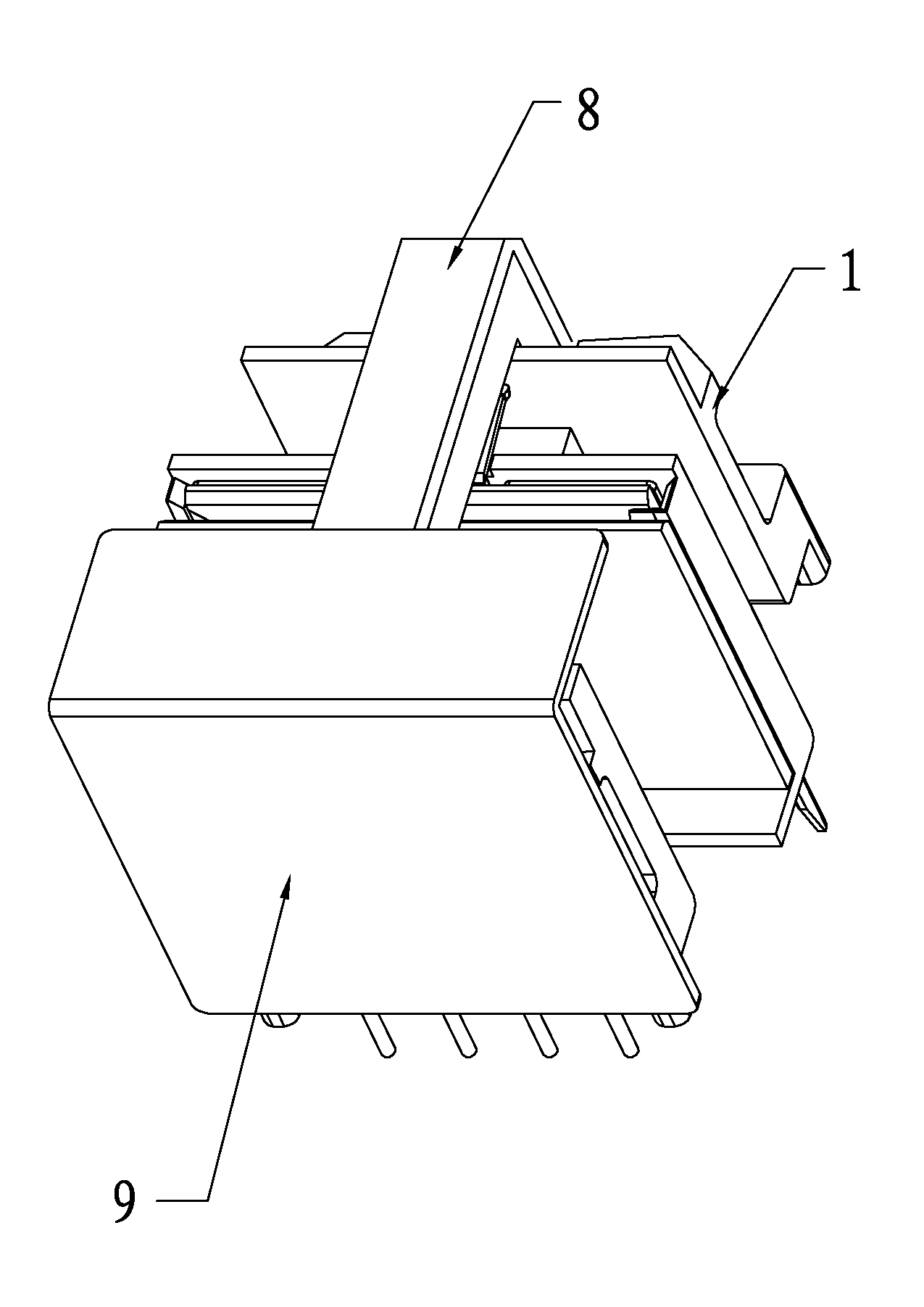

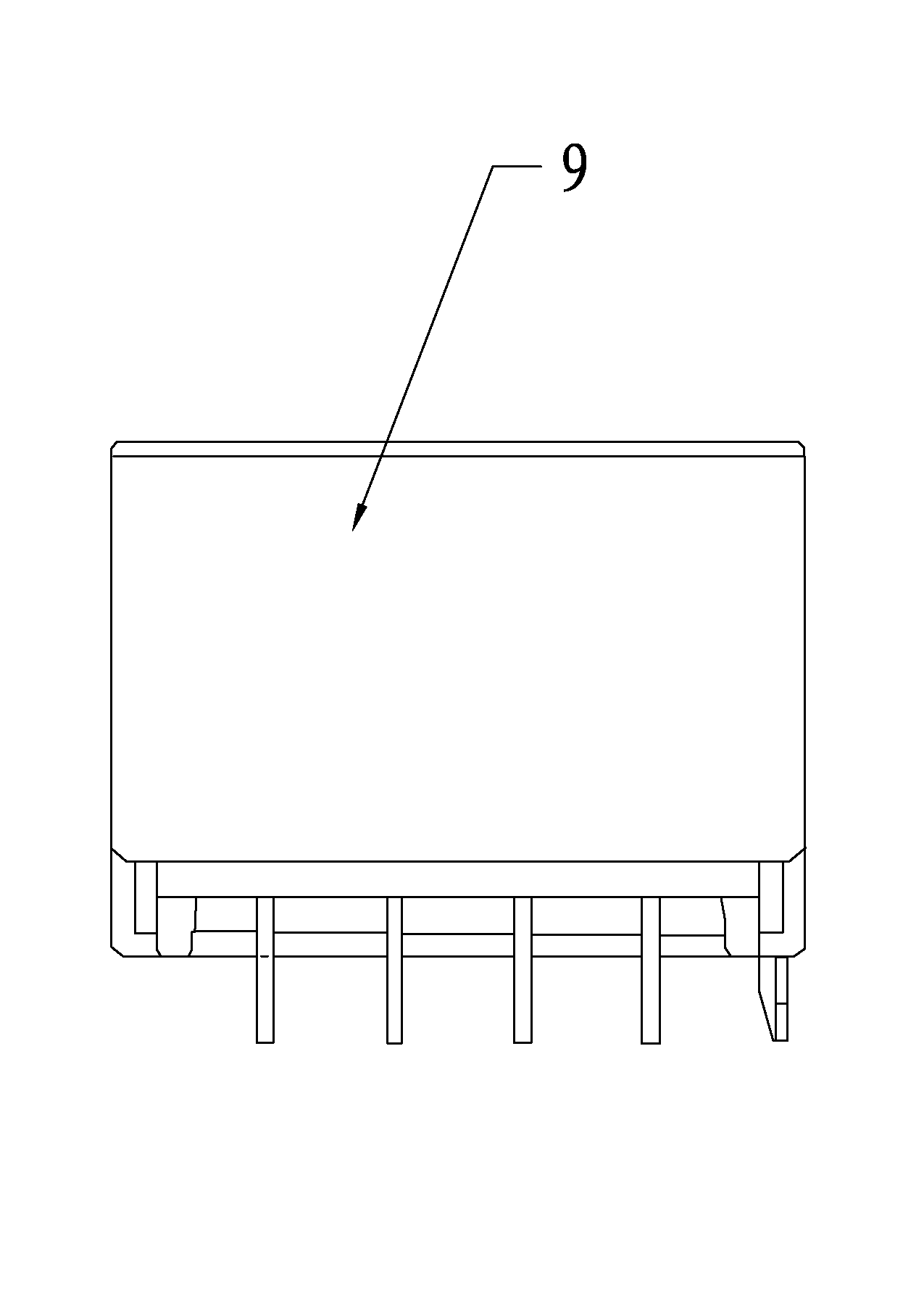

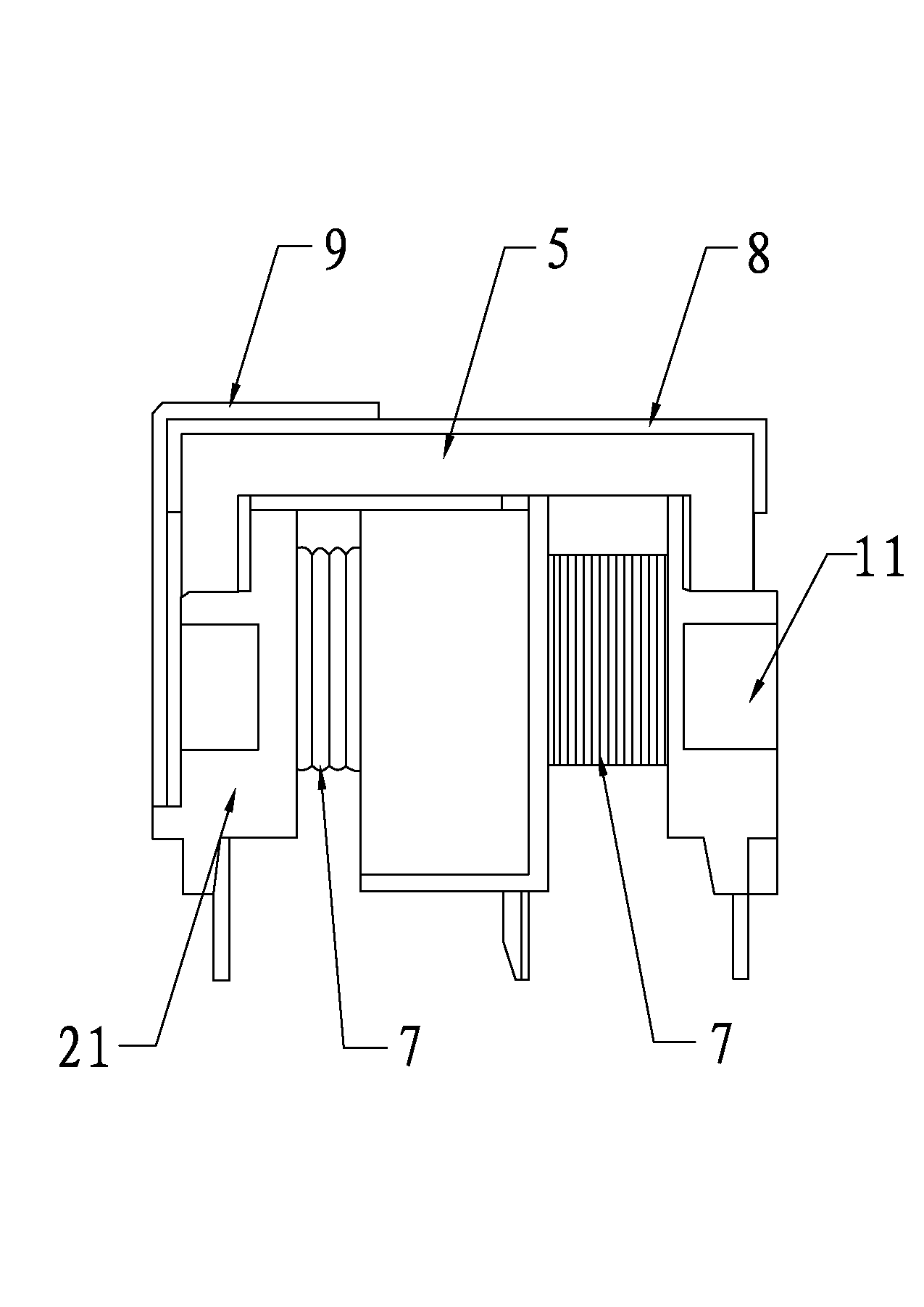

[0043] see Figure 1 to Figure 10 , the present invention will be described in detail below in conjunction with the accompanying drawings.

[0044] An ultra-thin magnetic core 5 high-frequency transformer according to the present invention includes a primary wire package 1 and a secondary wire package 2, and a notch 3 is opened on one side of the primary wire package 1, and the notch 3 is embedded A copper sheet 4 is provided, the secondary wire package 2 is engaged with the notch 3, and the copper sheet 4 is located between the secondary wire package 2 and the notch 3; two magnetic cores 5 are also included, and the magnetic core 5 is a "U"-shaped structure, two magnetic cores 5 are respectively clamped on the top of the primary wire package 1 and the secondary wire package 2, and the opposite surfaces of the two magnetic cores 5 are in contact; the top of the copper sheet 4 A thin sheet 6 is arranged on one side of the primary wire package 1 , and the inner surface of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com