Chip reinforced boiling heat transfer structure of multi-pore microcolumn variable camber molded surfaces

A technology to enhance boiling and heat transfer structure, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of heat transfer deterioration on the surface of heating components, unfavorable liquid heating surface, increased fluid flow resistance, etc., to achieve the elimination of boiling The effect of increasing the initial temperature rise, improving the liquid transport efficiency, and reducing the fluid flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

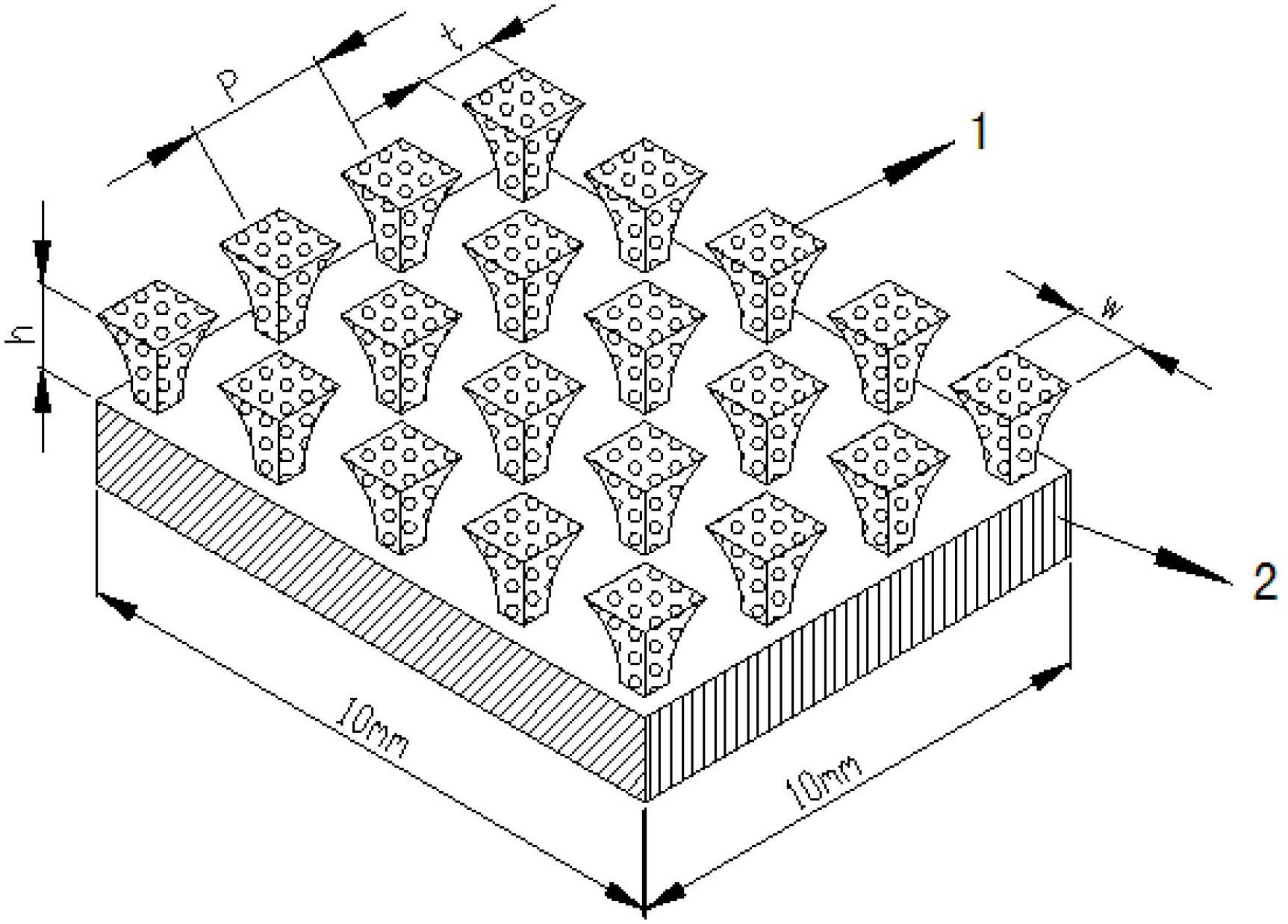

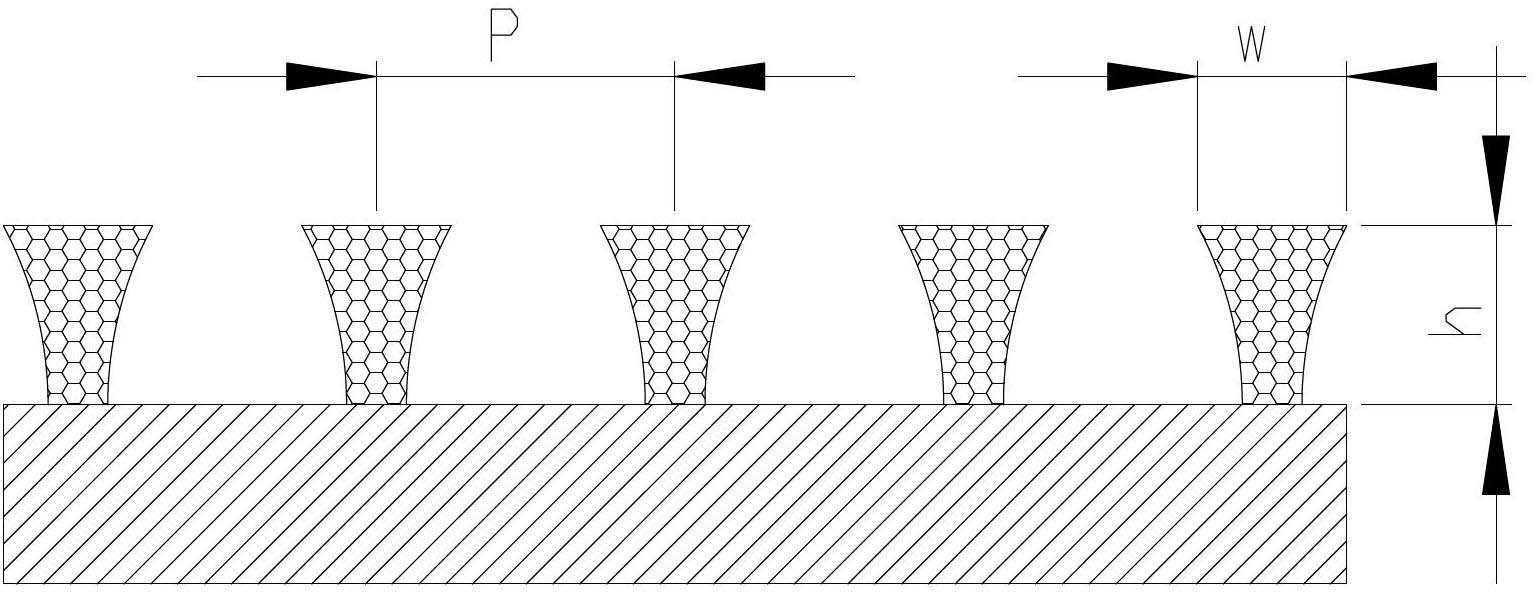

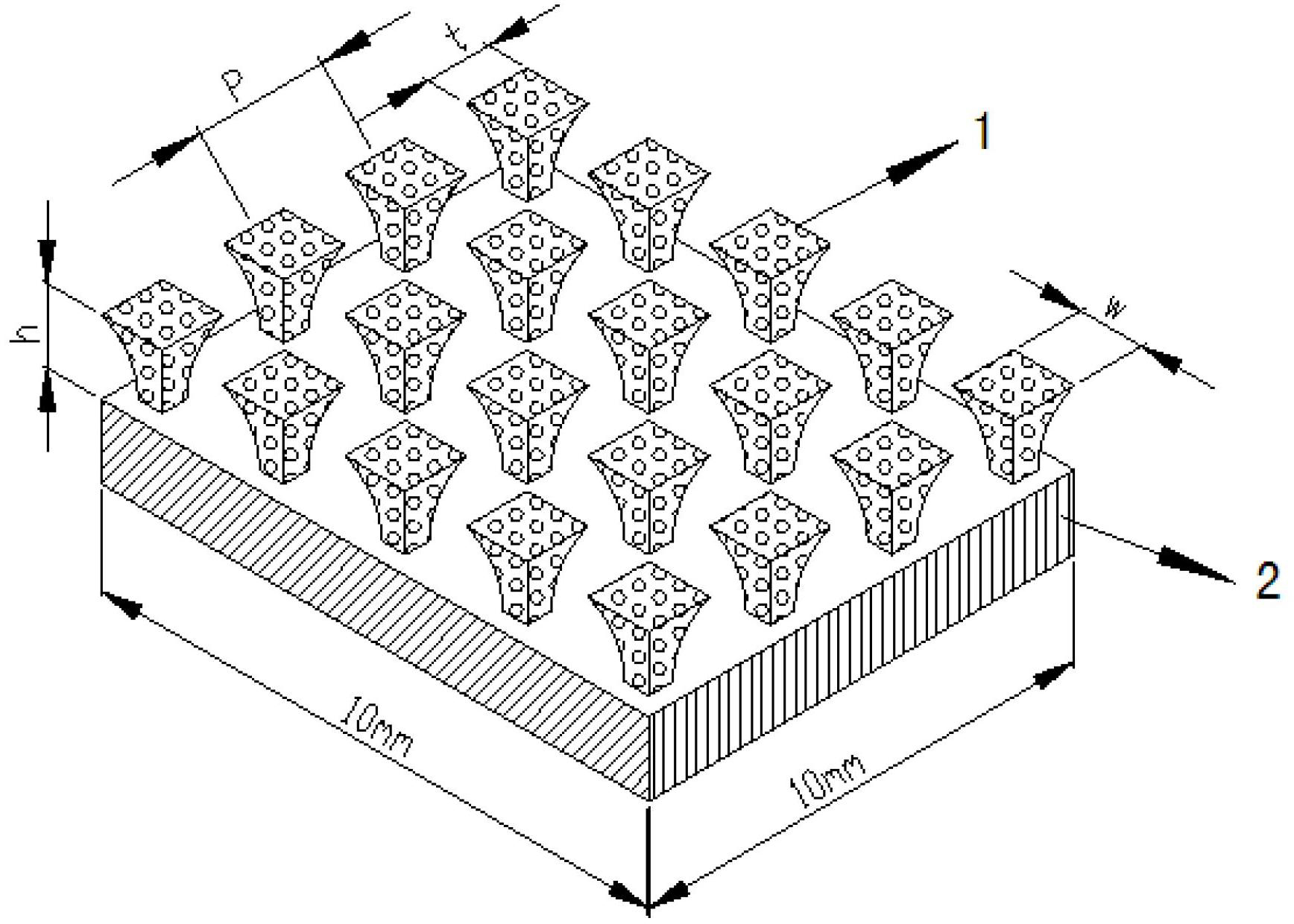

[0025] refer to figure 1 , the present invention includes a heat dissipation plate on the surface of the chip and a three-dimensional microstructure of several porous variable curvature profiles formed on the top of the heat dissipation plate 2 by using foam metal 1, wherein the upper and lower surfaces of the three-dimensional microstructure of the porous variable curvature profile are squares of different sizes, The side surfaces are arc surfaces of the same shape.

[0026]Due to the three-dimensional microstructure with curved shape, the use of traditional photolithography etching, wet etching and other technologies can no longer meet the needs. As early as 1993, a new microfabrication process was proposed by Japanese professor Ikuta (IKUTA K, HIROWATARI K, Real three dimensional micro fabrication using stereo lithography and metal molding [C], Proceeding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com