Synchronous pulse control circuit for preventing faults of microprogrammed control unit (MCU) or driving integrated circuit (IC)

A technology for controlling circuits and synchronous pulses, applied in pulse technology, pulse processing, pulse shaping, etc., can solve problems such as complex structure, high cost, and large volume, and achieve good reliability, low cost, and good followability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

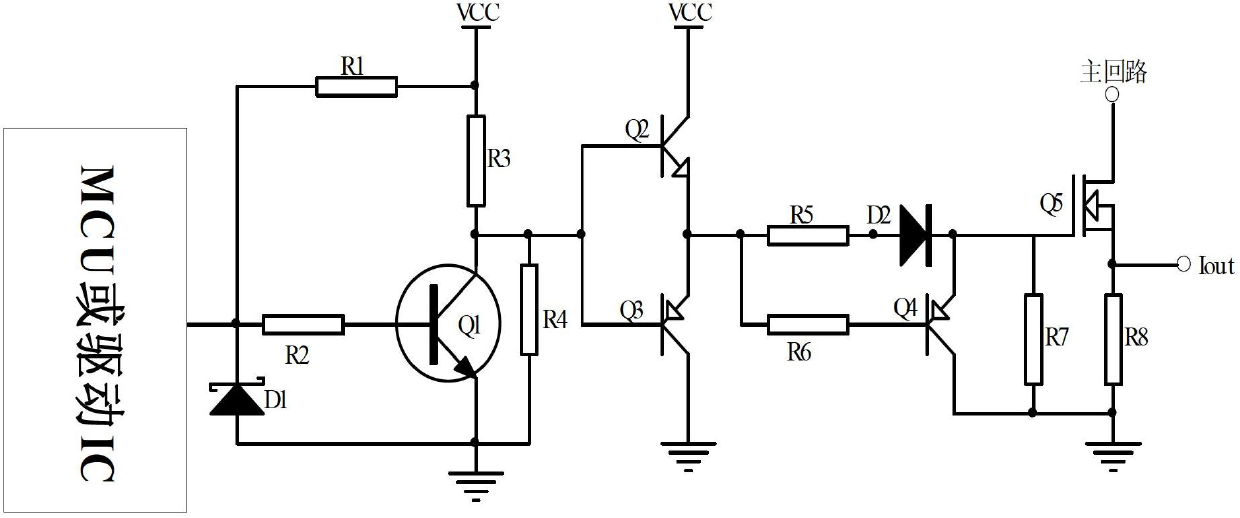

[0035] The realization scheme of the present invention is as Figure 11 The control circuit is shown in the dotted box. The synchronous pulse control circuit of the present invention includes a signal sampling circuit, a synchronous pulse conversion circuit and a shaping control signal output circuit.

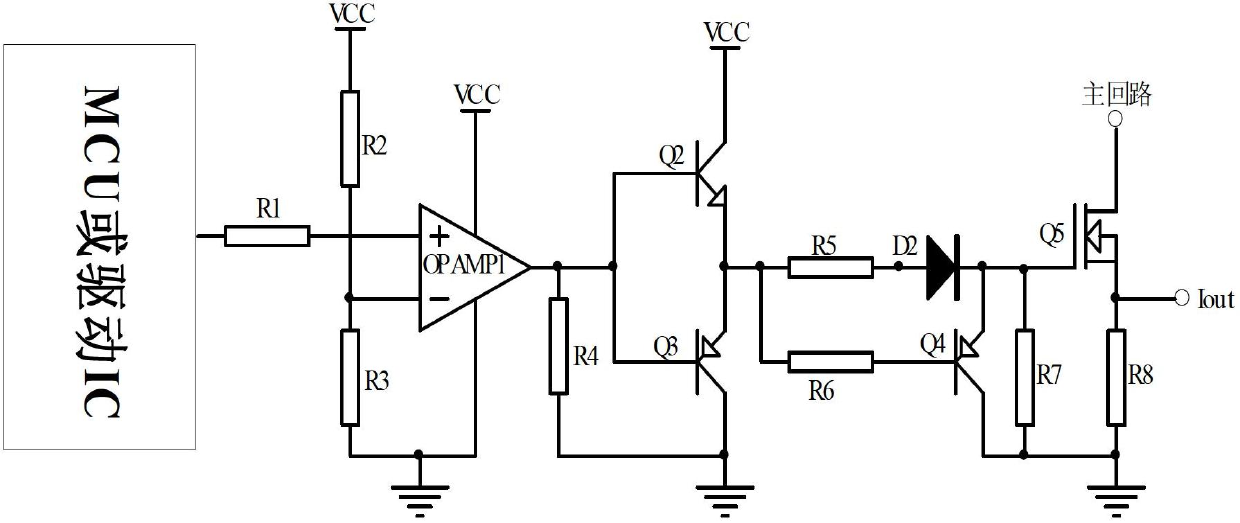

[0036] The signal sampling circuit consists of an operational amplifier OPAMP1 and a peripheral circuit composed of resistors R1, R2, R3 and R4. Among them: the series circuit composed of voltage dividing resistors R2 and R3 provides a reference voltage for the negative input terminal of the operational amplifier OPAMP1; one end of the resistor R1 is connected to the output terminal of the MCU or driver IC, and the other end is connected to the positive input terminal of the operational amplifier OPAMP1; the resistor R4 One end is connected to the output end of the operational amplifier OPAMP1.

[0037] Described synchronous pulse conversion circuit comprises pulse coupling c...

Embodiment 2

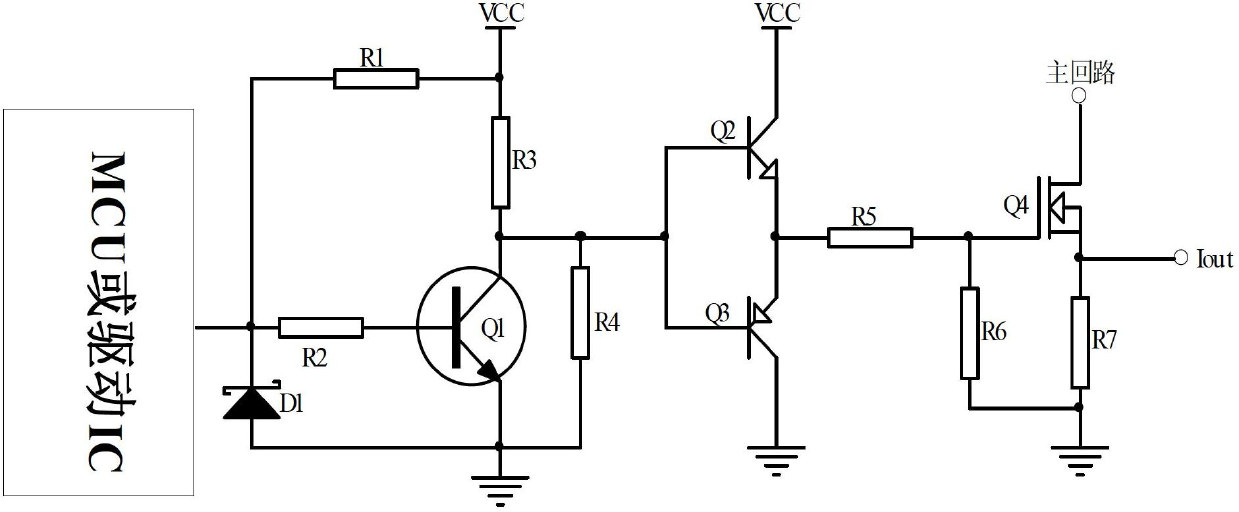

[0043] refer to Figure 12 , this example is in Figure 11 Improvements based on the examples. and Figure 11 The difference between the embodiments is that the signal sampling circuit is composed of a resistor R4, and the rest of the structures are the same as Figure 11 The embodiment is the same.

Embodiment 3

[0045] refer to Figure 13 , this example is in Figure 11 Improvements based on the examples. and Figure 11 The difference of the embodiments is that the shaping circuit adopts a first-stage RC integration circuit, which is composed of a resistor R5 and a capacitor C2, and the rest of the structures are the same as Figure 11 The embodiment is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com