Flexible circuit board, chip on film and manufacturing method

A technology of flexible circuit boards and chip-on-chips, which is applied in the fields of printed circuit manufacturing, printed circuits, and printed circuits, and can solve problems such as difficulty in overlapping lead wires of chip-on-chip liquid crystal panels, large expansion coefficients, and abnormal signal transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

[0029] The present invention provides a new type of flexible circuit board. This implementation mode takes chip-on-film as an example to further illustrate the concept of the present invention:

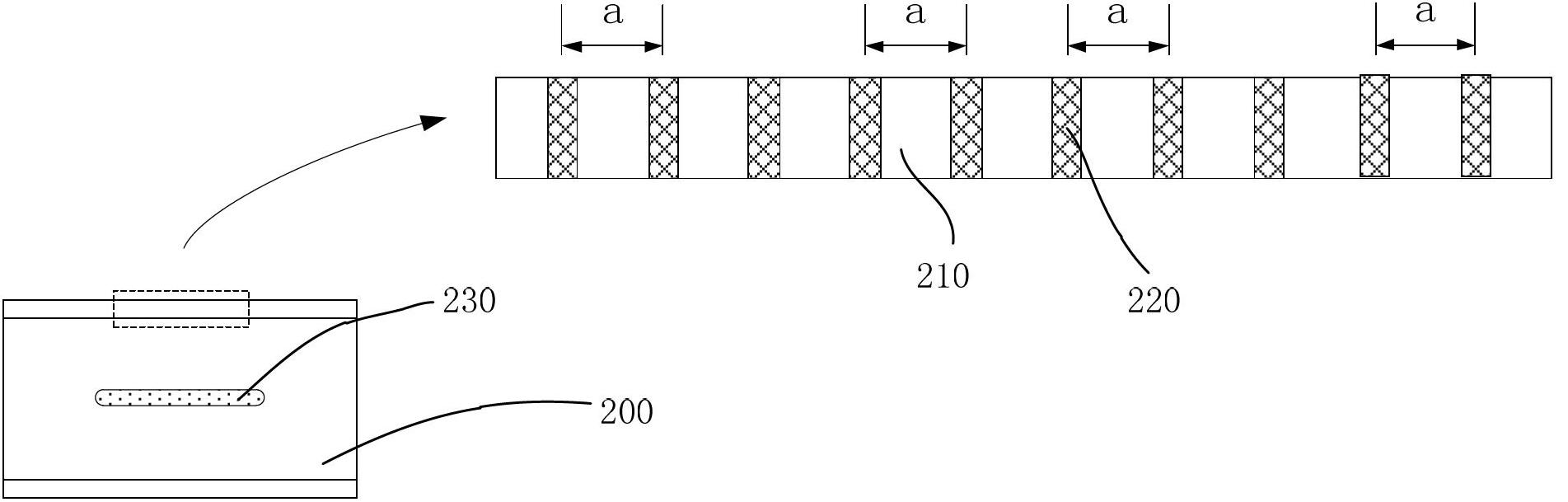

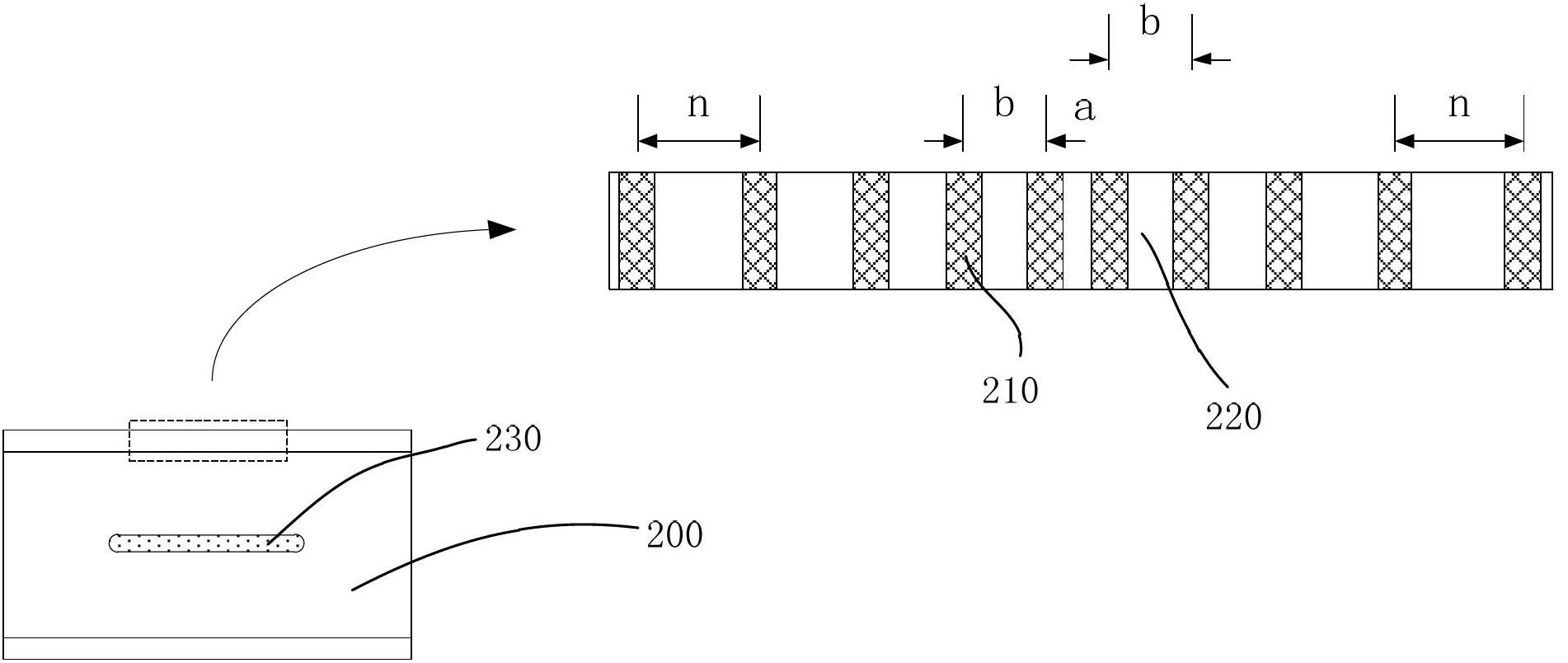

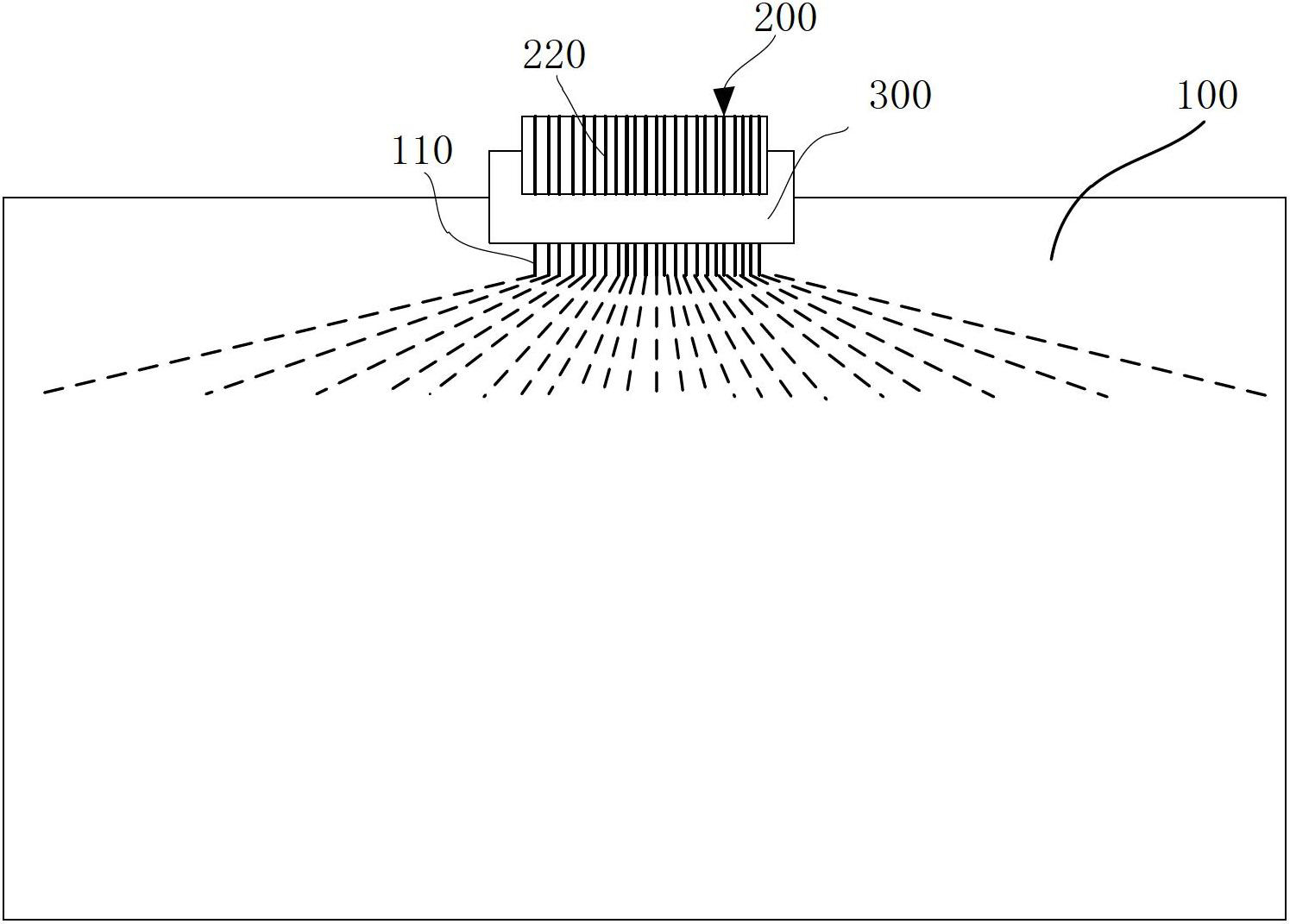

[0030] Such as Figure 2~3 As shown, the liquid crystal panel is provided with a plurality of criss-cross scan lines and data lines, and the distance between the scan lines and data lines at the edge of the liquid crystal panel 100 will be narrowed to form a plurality of lead lines. The COF 200 of the present invention comprises an insulating substrate 210 with elongated edges, an IC 230 is provided on the insulating substrate 210, pins 220 are arranged at both ends of the IC, and the pins 220 extend to two long sides of the insulating substrate 210 On the other hand, the pins of the chip-on-chip film 200 used for hot-pressing with the liquid crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com