Polylactic acid-based decorative body

A technology of polylactic acid and decorative body, which is applied in decorative art, decorative structure, transportation and packaging, etc., and can solve the problems of damage to incinerators, high volume occupancy, and large discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

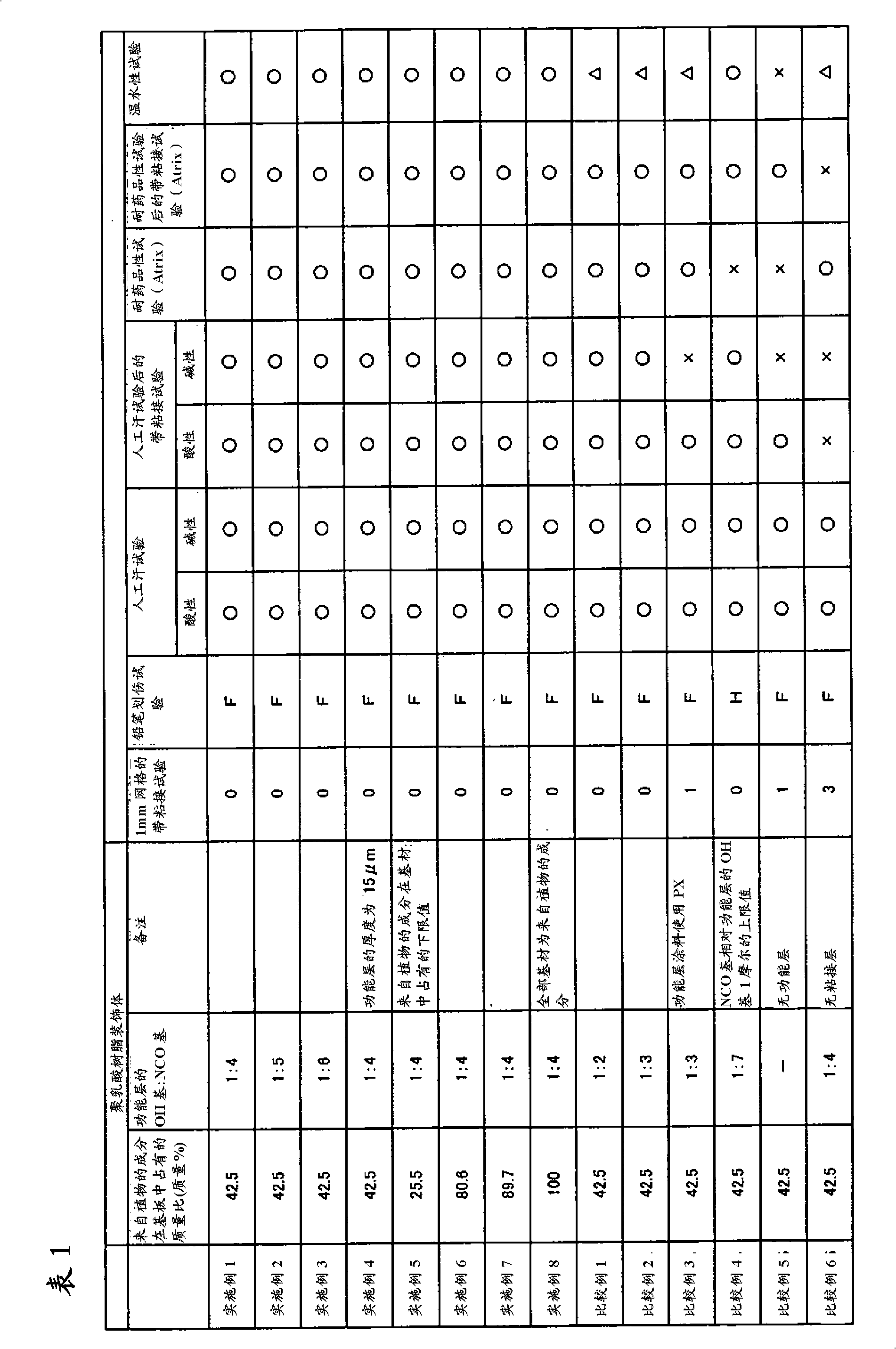

Examples

Embodiment 1

[0049] (1) Fabrication of Substrate 1

[0050]100 parts by mass of polylactic acid resin (TERRAMACTE-4000N, manufactured by UNITIKA, mass average molecular weight Mw in terms of polystyrene: 150000), 115.5 parts by mass of aluminum hydroxide (HIGILITE HP-350, manufactured by Showa Denko) as a flame retardant, 5 parts of phosphorus compound (sps-100, manufactured by Otsuka Chemical Industry), 1 part by mass of dripping preventive agent (POLYFLON MPA, manufactured by Daikin Industry), 2 parts by mass of hydrolysis inhibitor (Stabaxol P, manufactured by Rein Chemie), crystal nucleating agent (ECOPROMOTE, manufactured by Nissan Chemical) 2 parts by mass, and plasticizer (DAIFATTY-101, manufactured by Daihachi Chemical) 10 parts by mass were melt-kneaded at 180° C. using a twin-screw extruder (S1 KRCKneader, manufactured by Kurimoto) extrude. The extruded resin was cut into pellets to obtain a polylactic acid resin composition. Then, a test piece was molded by an injection moldin...

Embodiment 2

[0060] Except that the main ingredient of the coating for the functional layer is 100 parts by mass, and the curing agent is 27.8 parts by mass, according to Example 1, a polylactic acid-based decorative body is produced. The molar ratio of the OH groups contained in the acrylic resin and the NCO groups contained in the polyfunctional isocyanate compound in the paint for the functional layer was 1:5.

Embodiment 3

[0062] Except that the main ingredient of the coating for the functional layer is 100 parts by mass, and the curing agent is 33.3 parts by mass, according to Example 1, a polylactic acid-based decorative body is produced. The molar ratio of the OH groups contained in the acrylic resin and the NCO groups contained in the polyfunctional isocyanate compound in the functional layer coating material was 1:6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com