Sulfonate surfactant and preparation method thereof

A technology of surfactants and sulfonates, applied in the preparation of sulfonates, chemical instruments and methods, drilling compositions, etc., can solve the problems of poor salt resistance and temperature resistance, and achieve high temperature and salt resistance. , high surface activity, improve the effect of oil displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, a kind of sulfonate surfactant, is a kind of anionic-nonionic surfactant, structural formula is:

[0022]

[0023] Among them, R 1 for H.

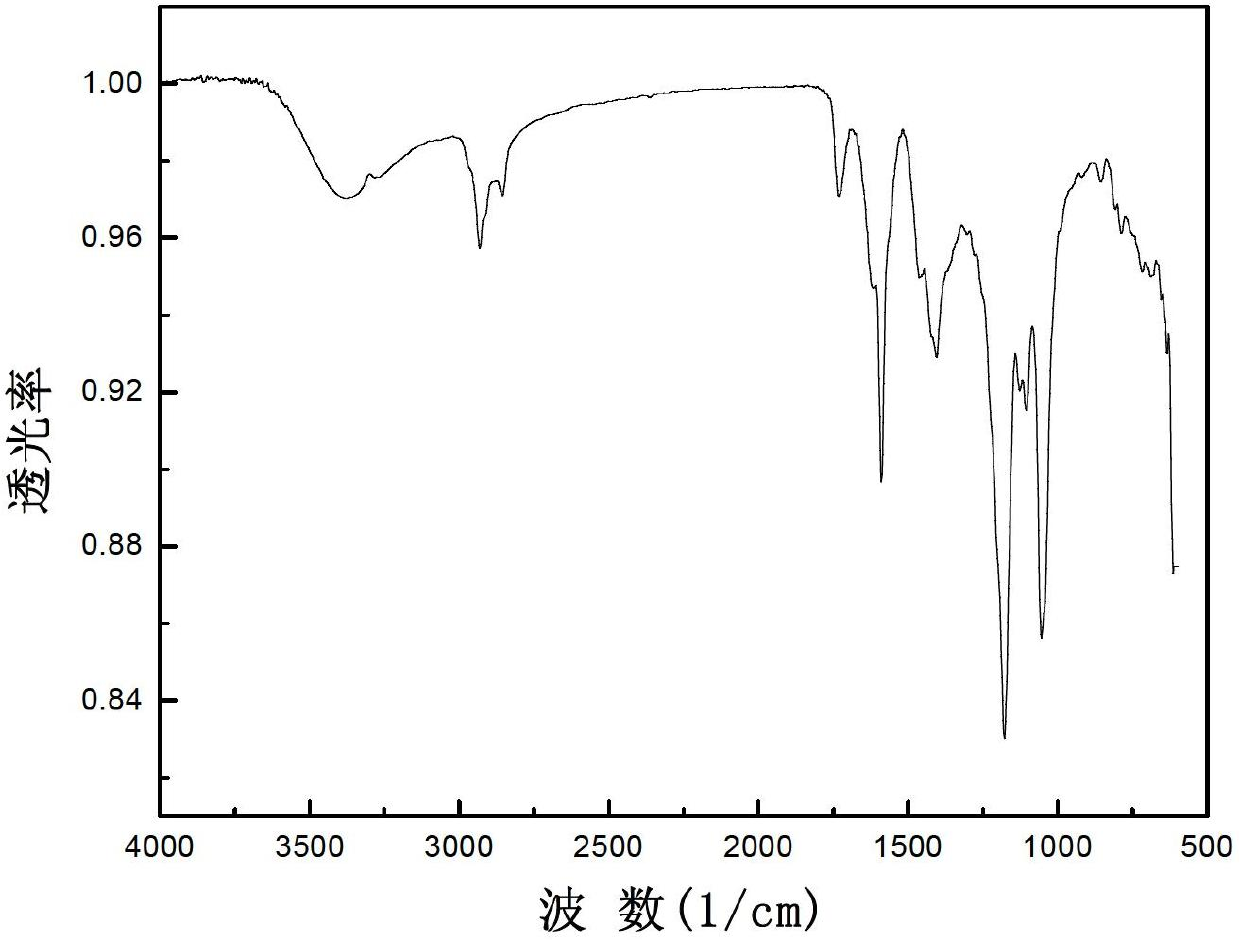

[0024] figure 1 Infrared spectrum of the sulfonate surfactant.

[0025] The preparation method of the sulfonate surfactant, the total number of carbon atoms in the acid used is 10-18, and the specific preparation steps are as follows:

[0026] Step 1: (1) First, dissolve 1 mol of diethanolamine in a certain amount of methanol, add dropwise 2 mol of methyl acrylate, stir at 35°C for 4 hours, and vacuum filter at 0.08MPa for 1 hour to obtain AB 2 monomer;

[0027] (2) Stir trimethylolpropane and 2% catalyst p-toluenesulfonic acid at 115°C, according to AB 2 The ratio of monomer to trimethylolpropane molar ratio is 2:1, add AB dropwise 2 The monomer was reacted at 100°C for 1 hour, and transferred to a rotary evaporator at 120°C for 1 hour to obtain a hydroxyl-terminated hyperbranched polymer.

[0028] Step 2: M...

Embodiment 2

[0032] Embodiment 2, a kind of sulfonate surfactant and preparation method thereof, referring to embodiment 1, differs from embodiment 1, in step 2, with step 1 gained terminal hydroxyl hyperbranched polymer and cinnamoyl chloride by 1: A molar ratio of 4 was mixed.

Embodiment 3

[0033] Embodiment 3, a kind of sulfonate surfactant and preparation method thereof, refer to embodiment 1, and embodiment 1 is different, step 2: the hydroxyl end hyperbranched polymer obtained in step 1 and oleic acid are 1:4 The molar ratio is mixed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com