Suspension culture production method for porcine circovirus 2-type cells

A porcine circovirus, cell suspension technology, applied in microorganism-based methods, biochemical equipment and methods, viruses/phages, etc., can solve the problem of high labor, site and raw material costs, difficulty in meeting vaccine requirements, and difficulty in expanding production, etc. problem, to achieve the effect of simple and stable production process, expansion of production scale, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

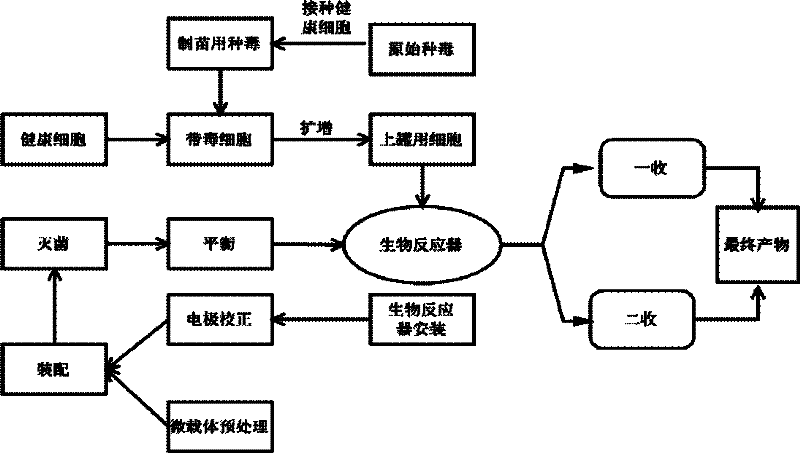

Image

Examples

Embodiment 1

[0035] A kind of porcine circovirus type 2 cell suspension culture production method, comprises the steps:

[0036] (1), Subculture and cultivation of healthy cells

[0037] The pK-15 clone cells were digested and passaged with trypsin digestion solution, cultured in cell growth medium at a temperature of 37.0°C (±0.2)°C; when a good cell monolayer was formed, it was used for further passage or inoculated in a bioreactor microcarrier culture;

[0038] (2), preparation and passage of toxic cells

[0039] Digest and passage the healthy pK-15 clone cells with good cell condition and grow into a single layer, then inoculate PCV2 seed virus according to 5% of the cell culture volume, culture for 48 hours, and after the cells grow to more than 50%, change the maintenance solution containing MEM and continue to maintain for 48 hours. After the cells are full, the F1 generation of toxic cells can be obtained; gently wash the F1 generation of toxic cells with preheated sterile PBS bu...

Embodiment 2

[0061] A kind of porcine circovirus type 2 cell suspension culture production method, comprises the steps:

[0062] (1), Subculture and cultivation of healthy cells

[0063] The pK-15 clone cells were digested and passaged with trypsin digestion solution, cultured in cell growth medium at a temperature of 37.0°C (±0.2)°C; when a good cell monolayer was formed, it was used for further passage or inoculated in a bioreactor microcarrier culture;

[0064] (2), preparation and passage of toxic cells

[0065] Digest and passage the healthy pK-15 clone cells with good cell condition and grow into a monolayer, then inoculate PCV2 seed virus according to 1% of the cell culture volume, culture for 24 hours, and after the cells grow to more than 50%, change the maintenance solution containing MEM and continue to maintain for 48 hours. After the cells are full, the F1 generation of toxic cells can be obtained; gently wash the F1 generation of toxic cells with preheated sterile PBS buffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com