Copper alloy tube for heat exchange

A technology of heat exchangers and copper alloys, applied in the field of copper alloy tubes for heat exchangers, can solve the problems of high product prices and disadvantages, and achieve the effects of increased extrusion pressure, improved processability, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

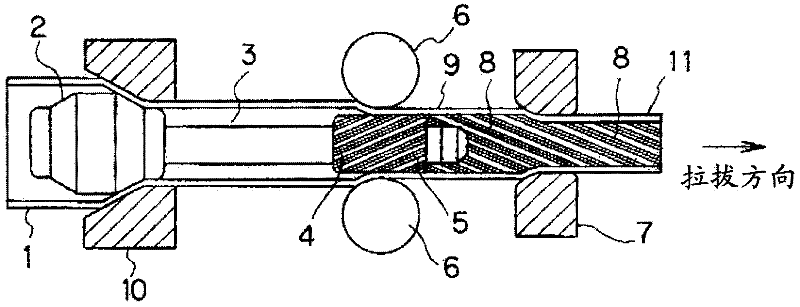

Method used

Image

Examples

no. 1 Embodiment approach

[0052] The copper alloy tube for a heat exchanger according to the first embodiment of the present invention contains 0.1-1.0% by mass of Mn, 0.05-0.5% by mass of Fe, and 0.01-0.1% by mass of P. The mass ratio of Fe to P (Fe The copper alloy whose / P) is 2-8 and the remainder is Cu and inevitable impurities is formed into a tube shape.

[0053] A copper alloy containing 0.1 to 1.0% by mass of Mn is used as a material. Mn exists in copper in a solid solution state and is a component that contributes to the improvement of strength. In addition, by coexisting with P, a part is converted into a P compound and precipitated, so it is a component that can also expect a precipitation strengthening effect.

[0054] In addition to the prescribed amounts of Mn, Fe, and P, the mass ratio (Fe / P) is in the range of 2 to 8 containing 0.05 to 0.5 mass% of Fe and 0.01 to 0.1 mass% of P. Fe is added together with P and precipitates in the material as a P compound. Therefore, Fe is added for the pu...

no. 2 Embodiment approach

[0061] The copper alloy tube for a heat exchanger according to the second embodiment of the present invention uses copper to which a predetermined amount of one or both of Ni and Co is added to the composition of the copper alloy of the first embodiment. Alloy tube.

[0062] That is, the copper alloy tube for heat exchanger of this embodiment contains 0.1 to 1.0 mass% of Mn, 0.05 to 0.5 mass% of Fe, and 0.01 to 0.1 mass% of P, and contains a total of 0.01 to 0.25 mass% of Ni. With one or two of Co, the mass ratio of the total of Fe, Ni, Co to P {(Fe+Ni+Co) / P} is 2-8, and the remainder is copper with Cu and unavoidable impurities The alloy is formed into a tube.

[0063] Next, the reason for the numerical limitation of the components of the copper alloy described above will be explained below. In addition, since the reason for limiting the addition amount of Mn, P, and Fe and the mass ratio of Fe to P is the same as in the first embodiment, the description thereof is omitted here....

no. 3 Embodiment approach

[0069] The copper alloy tube for a heat exchanger according to the third embodiment of the present invention uses one or more selected from Sn, Zn, In, and Mg with a predetermined amount added to the composition of the copper alloy of the first embodiment The composition of the copper alloy copper alloy tube.

[0070] That is, the copper alloy tube for a heat exchanger of the present embodiment contains 0.1 to 1.0% by mass of Mn, 0.05 to 0.5% by mass of Fe, and 0.01 to 0.1% by mass of P, and contains 0.01 to 0.3% by mass in total. One or more components selected from Sn, Zn, In, and Mg, the mass ratio of Fe to P (Fe / P) is 2-8, and the remainder is a copper alloy with Cu and unavoidable impurities formed into a tube and to make.

[0071] Next, the reason for the numerical limitation of the components of the copper alloy described above will be explained below. In addition, since the reasons for limiting the addition amounts of Mn, P, and Fe and the mass ratio of Fe to P are the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com