Ecological antiflaming engraved woolen cloth and preparation method thereof

An ecological and production line technology, applied in the direction of digging fabrics, fabrics, textiles, etc., to achieve the effects of evenness, reliable engraving, and improved spinning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

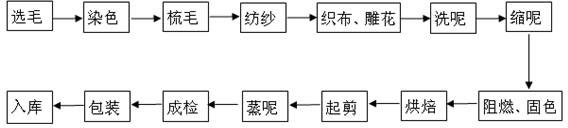

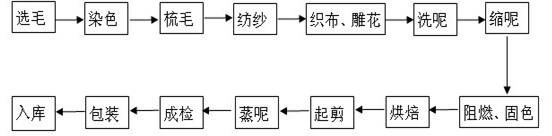

[0051] A preparation method of ecological flame-retardant carved pattern, characterized in that it comprises the following steps:

[0052] 1) Wool selection, dyeing, carding, spinning

[0053] The mercerized wool, bamboo fiber, and hemp fiber are selected and dyed respectively, and then fully mixed with Croslube TCA carding lubricant with a weight ratio of 4.5% through the wool machine, and then packed and left for 48 hours to be evenly combed; Ratio: 60% mercerized wool, 28% bamboo fiber, 12% hemp fiber, spun by German Saurer Textile Machinery production line to obtain 19 S ecological fiber yarn;

[0054] 2) Weaving and carving

[0055] Control the warp density between 120 strands / 10cm-145 strands / 10cm, and the Victoria's Secret between 110 strands / 10cm-116 strands / 10cm for weaving treatment; use composite weave, striped weave and concave-convex Combination of tissues for engraving;

[0056] 3) Washing and shrinking

[0057] Wash and shrink the fabric, use No. 105 neutra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com