Technique for raising storage content of stockpiled tailing reservoir

A process method and technology of tailings ponds, which are applied in the technological field of increasing the storage capacity of stockpiled tailings ponds, can solve problems such as prominent environmental problems, increased tailings transportation distance, and increased investment costs, and achieve enhanced stability and reduced Lateral force action, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

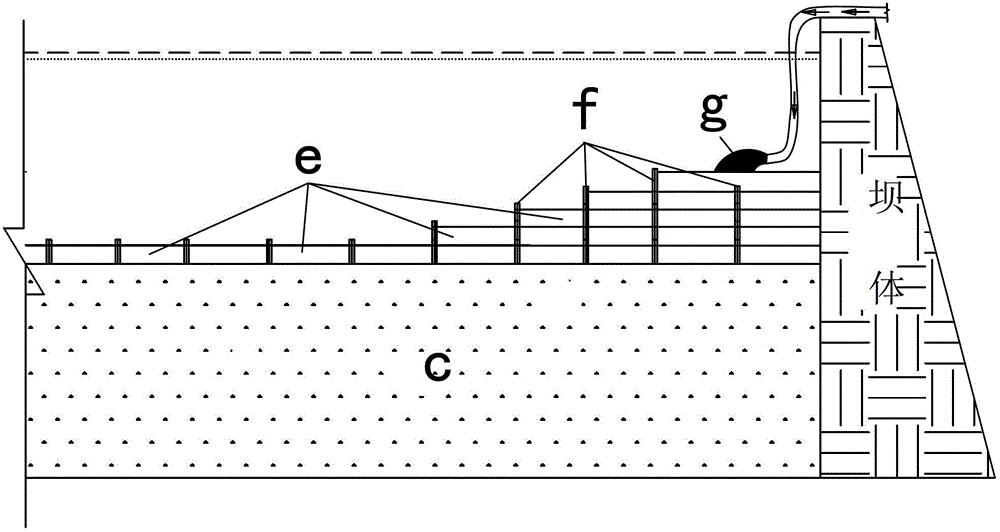

[0034] A bauxite tailings pond with a full storage capacity, the top surface area of the pond is 120 hectares, the tailings dam is 25m high, and the current daily discharge of tailings mud is 20,000 m 3 , using the method provided by the invention to increase the storage capacity of the tailings pond. The specific method is as follows:

[0035] Due to the short stockpiling time, the free water on the surface has been basically drained, but the average pore ratio of the mud is still as high as 1.2, the pores are relatively large, the density is small, and the bearing capacity is small. The tailings slurry is medium-coarse sand with a clay content of 5% by mass. The tailings pond is expanded according to the following process steps:

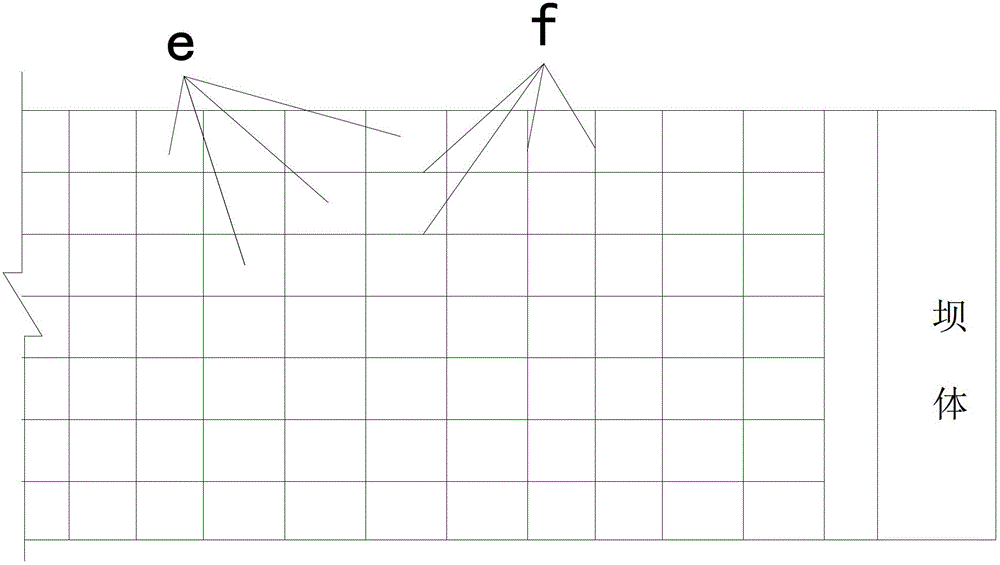

[0036] ①The stockpiled tailings slurry in the tailings pond is medium-coarse sand and the mass percentage of clay is less than 10%. The single-point vibrating compaction construction technology is used to drain and densify the stockpiled tailin...

Embodiment 2

[0041] A bauxite tailings pond that is being stockpiled has a roof area of 250 hectares, a tailings dam height of 30m, and the current daily discharge of tailings slurry is 15,000m 3 , using the method provided by the invention to increase the storage capacity of the tailings pond. The specific method is as follows:

[0042] The tailings pond that has already been stockpiled belongs to the tailings pond that is being stockpiled. Since the tailings slurry is still being discharged, the overall water content of the tailings slurry is very high. The average void ratio of the slurry is 1.8, and the tailings slurry cannot directly withstand construction. Mechanical and personnel operations, and tailings mud belongs to cohesive soil. The tailings pond is carried out according to the following process steps:

[0043] ①Set a vertical drainage pipe in the tailings mud, and then lay a 40cm sand cushion on the mud surface to form a horizontal drainage channel, which is covered with a...

Embodiment 3

[0047] A full-capacity iron ore tailings pond with a roof area of 80 hectares and a tailings dam height of 20m. The current daily discharge of tailings mud is 12,000 m 3 , using the method provided by the invention to increase storage capacity. The specific method is as follows:

[0048] After a long period of free deposition of the mud stored in the tailings pond of the full storage capacity, the surface free water has been drained, and the average pore ratio of the mud is 0.8. The tailings mud has relatively small pores, high density, and high bearing capacity. And the tailings mud belongs to fine sand and the clay is close to 20%. The tailings pool is carried out sequentially according to the following process steps:

[0049] ①The tailings mud is fine sand and the clay is close to 20%. The three-point vibratory compaction process is used to drain and densify the stockpiled tailings mud. Three models of ZCQ-30 and motor power of 30kW are used The vibrator produces high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com