Material non-destructive inspection method and device based on nonlinear acoustics

A nonlinear acoustic and non-destructive testing technology, which is applied in the processing of detection response signals, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as restricting development and application, reducing axial resolution, and reducing the ability to detect small defects. , to improve detection capability, reduce non-linearity, benefit cost and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

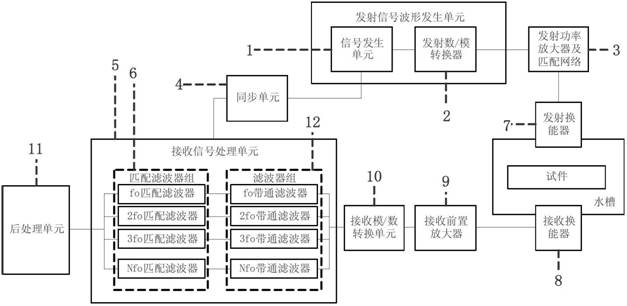

[0095] Such as Figure 7 As shown, a material non-destructive testing device based on nonlinear acoustics (see Figure 7 ), including: a scanning platform for mechanically scanning the specimen, a signal generating unit 1, a transmitting digital / analog converter 2, a transmitting power amplifier and a matching network 3, a synchronization unit 4, a receiving signal processing unit 5, and a transmitting transducer Device 7, receiving transducer 8, receiving preamplifier 9, receiving analog / digital conversion unit 10,

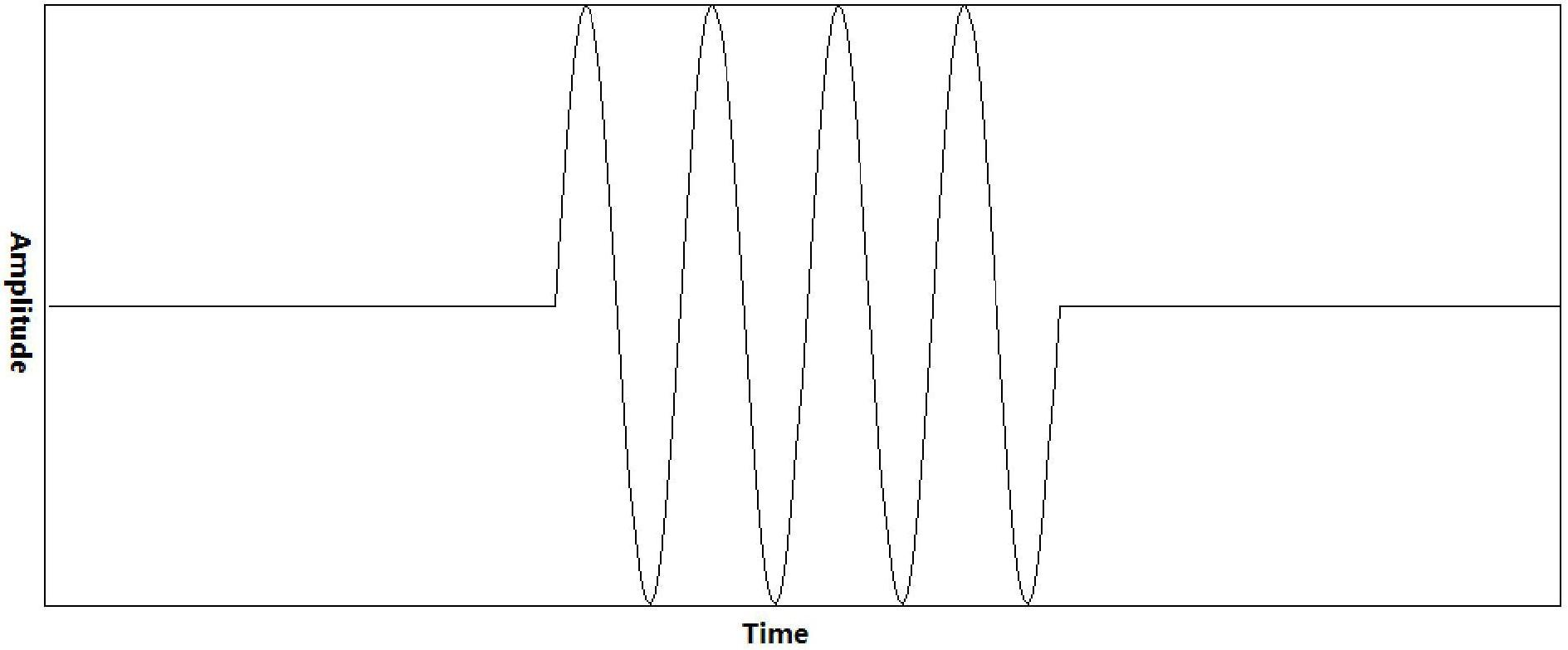

[0096] The signal generation unit 1 is used to generate a Gaussian envelope transmission signal, the unit generates the data of all sampling points of the transmission signal, and then sends the generated data into the transmission D / A converter 2 to convert it into an analog signal; the signal generation unit 1 It is connected with the transmission power amplifier and matching network 3, and the generated signal is sent to the transmission power amplifier for a...

Embodiment 2

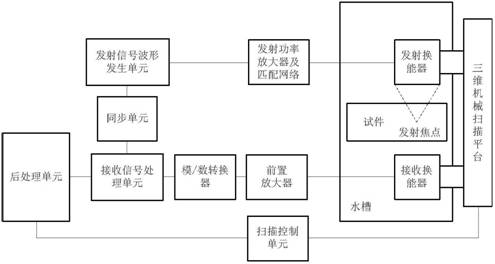

[0106] Such as Figure 8 As shown, the transmitting and receiving transducers are mounted on a three-dimensional precision mechanical scanning device. By positioning the transducer at a specific position of the test piece by the scanning device, and then performing the above-mentioned transmitting-receiving-processing steps, the nonlinear acoustic characteristics of the test piece located at the focal point of the transmitting transducer can be obtained. Through the movement of the scanning device, changing the relative position of the transmitting transducer and the test piece, and repeating the above steps at each position, the scanning of the whole test piece can be realized. In particular, by using a transmitting transducer with a small relative aperture (F number) to obtain a small axial focal length, combined with the higher axial resolution of this method, it is possible to achieve Scanning in the direction of the sound beam can complete the three-dimensional nonlinear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com