Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the direction of semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of weak response signal strength and high unit production cost, and achieve the effect of facilitating absorption and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

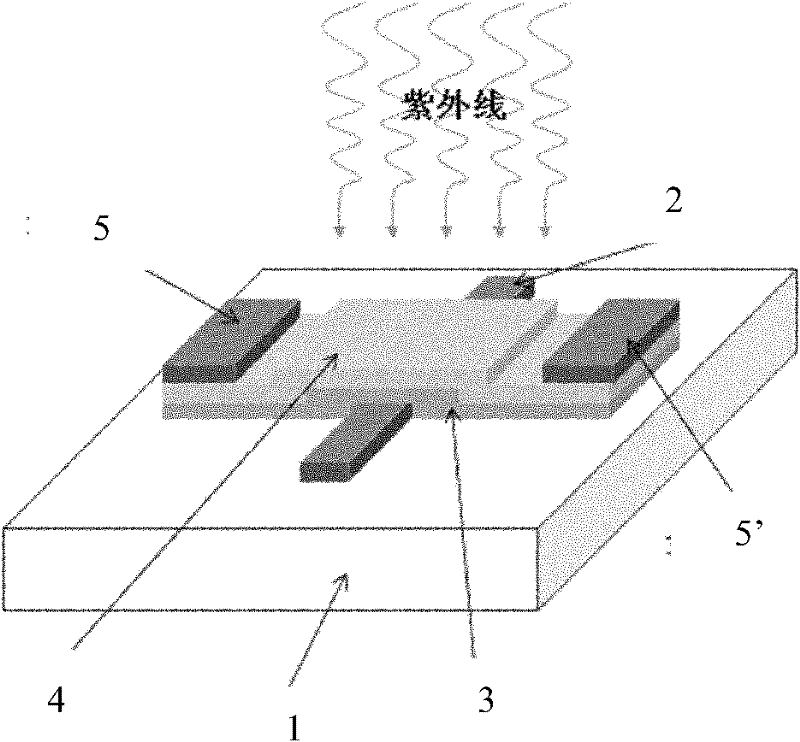

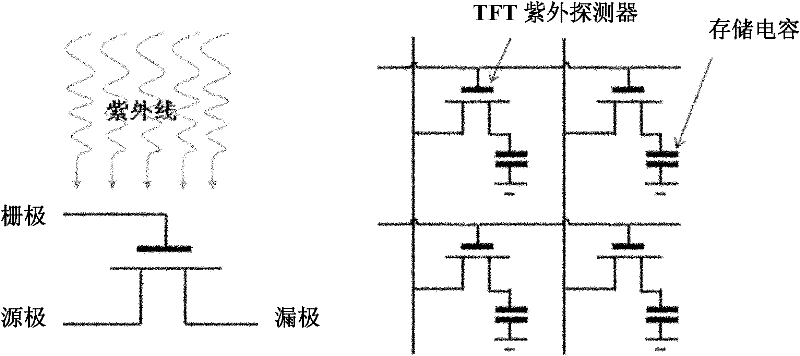

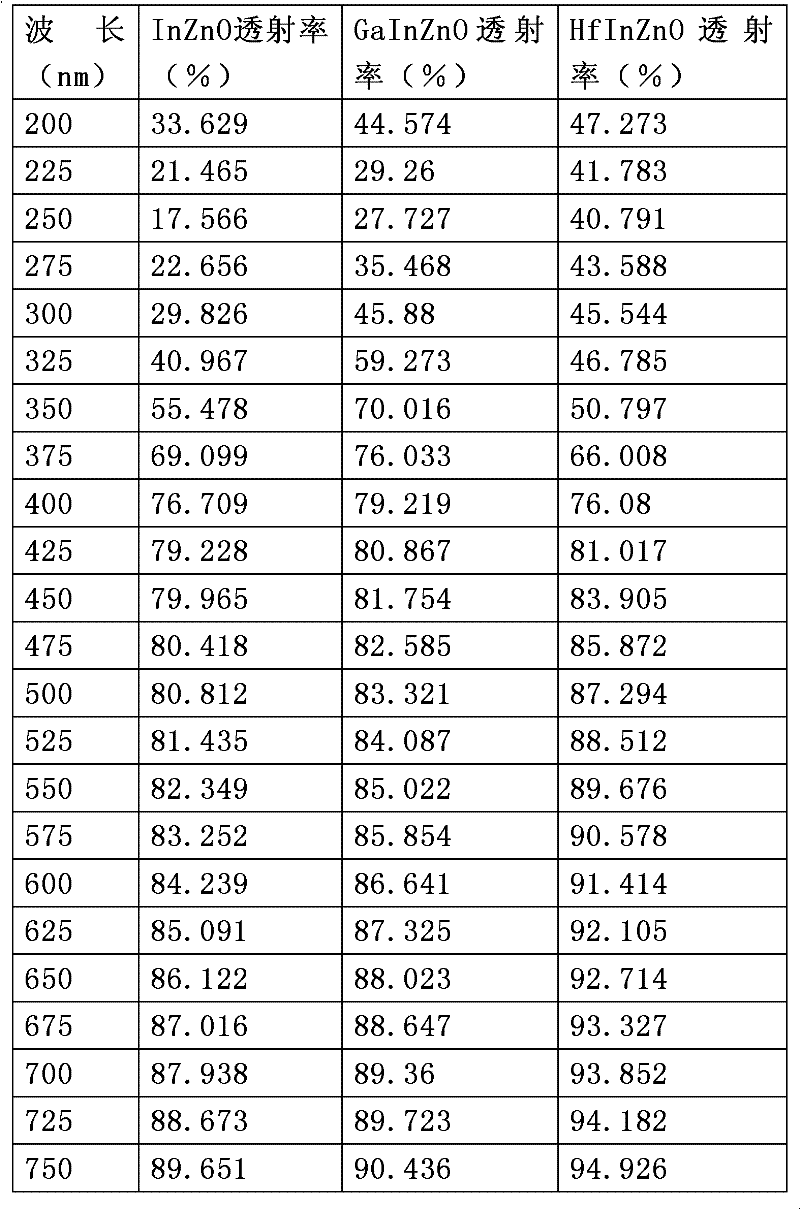

[0021] In order to make the objectives, technical solutions and advantages of the present invention clearer, the features and technical effects of the technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and in conjunction with illustrative embodiments. A low-cost large-size amorphous material is disclosed. State oxide semiconductor TFT type ultraviolet detector and its manufacturing method. It should be pointed out that similar reference signs indicate similar structures, and the terms "first", "second", "upper", "lower", etc. used in this application can be used to modify various device structures. Unless otherwise specified, these modifications do not imply the spatial, order, or hierarchical relationship of the modified device structure.

[0022] Such as figure 1 As shown, the present invention is a thin film transistor (TFT) type ultraviolet detection device, which includes a substrate 1, a back gate elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com