Preparation method of sunlight-responding mesoporous Bi2WO6 microspheres

A technology of sunlight and microspheres, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as limiting the use of sunlight, and achieve high photocatalytic activity, low cost, and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A solar-light-responsive mesoporous Bi 2 WO 6 The preparation method of the microspheres is prepared by a hydrothermal method, and the steps are as follows:

[0023] 1) Mix 0.002mol Bi(NO 3 ) 3 ·5H 2 O was dissolved in 20mL of distilled water to prepare bismuth nitrate suspension;

[0024] 2) Under the condition of magnetic stirring, 0.001mol Na 2 WO 4 2H 2 O was dissolved in 20mL distilled water to obtain an aqueous solution of sodium tungstate;

[0025] 3) Add the sodium tungstate aqueous solution dropwise to the bismuth nitrate suspension under magnetic stirring conditions to prepare the precursor solution;

[0026] 4) Put the precursor solution into a 50mL PTFE-lined hydrothermal kettle for hydrothermal reaction. The filling capacity of the precursor solution is 80%, the hydrothermal temperature is 150°C, and the hydrothermal reaction time is 24h;

[0027] 5) The product after the hydrothermal reaction was centrifuged, washed with water and absolute ethanol...

Embodiment 2

[0033] A solar-light-responsive mesoporous Bi 2 WO 6 The preparation method of the microspheres is basically the same as in Example 1, except that the hydrothermal temperature is 120°C.

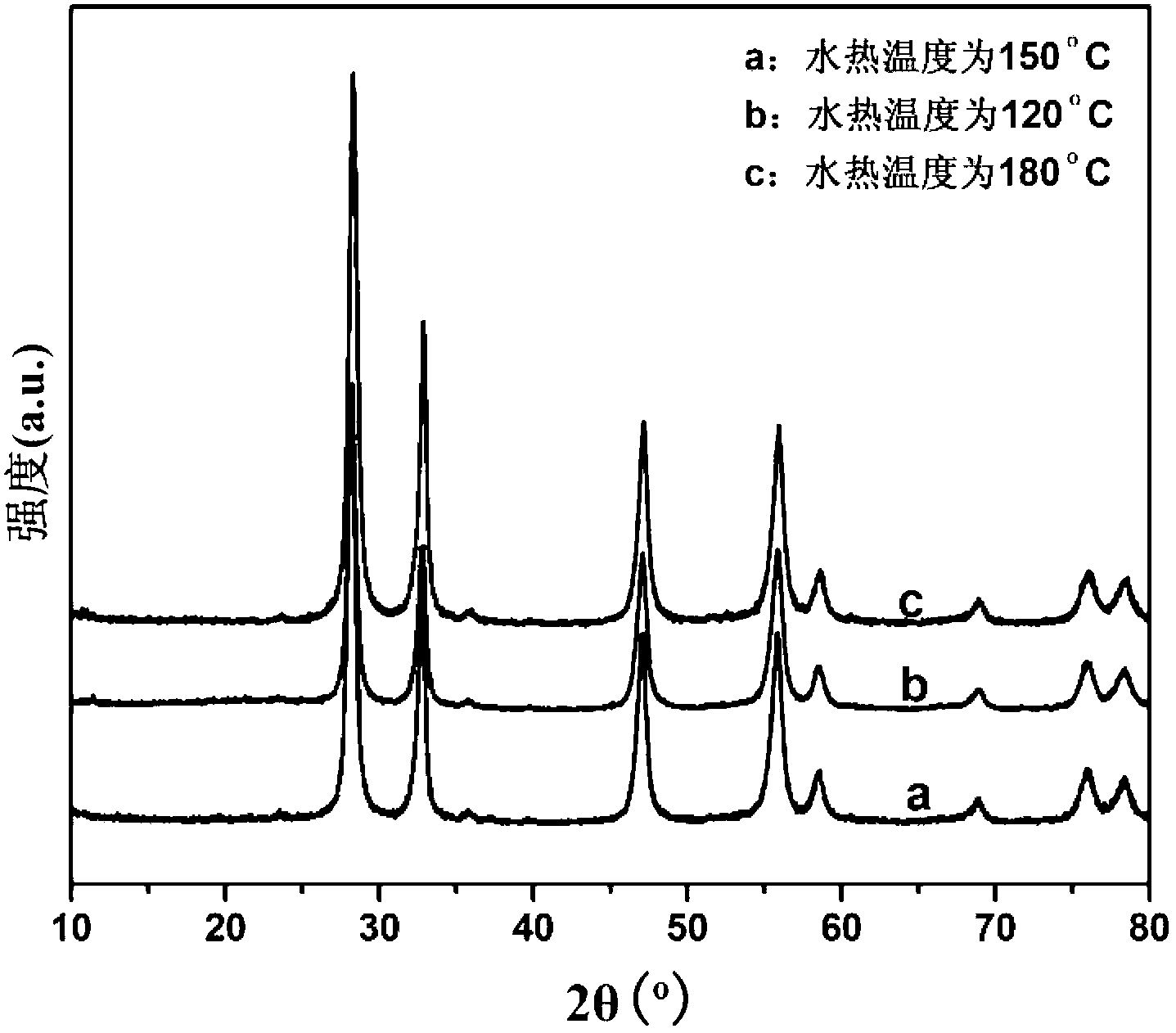

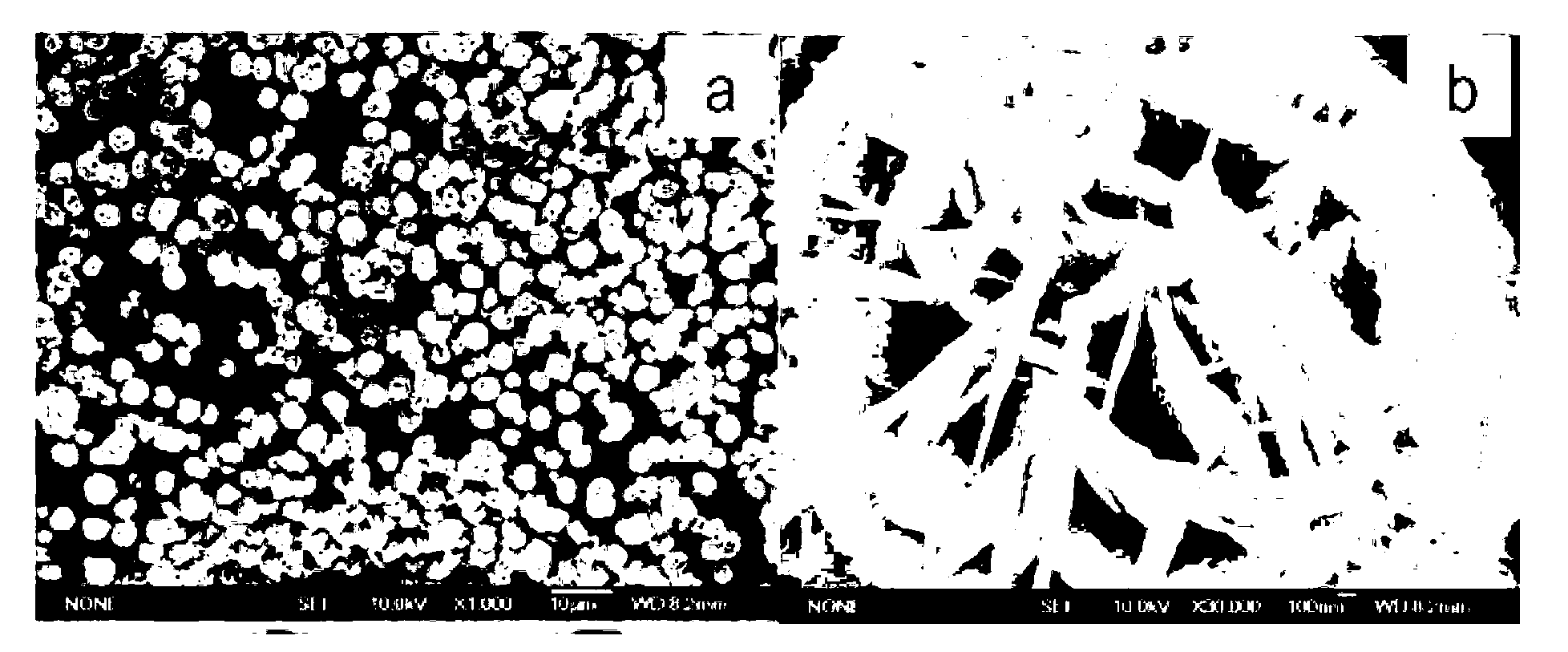

[0034] The sample prepared in this example shows that it is the Bi of orthorhombic system through XRD analysis. 2 WO 6 structure, such as figure 1 As shown in b, the sample is composed of flake-like particles, and its photocatalytic degradation efficiency of rhodamine B is 92% after 60 min of simulated sunlight irradiation.

Embodiment 3

[0036] A solar-light-responsive mesoporous Bi 2 WO 6 The preparation method of the microspheres is basically the same as in Example 1, except that the hydrothermal temperature is 180°C.

[0037] The sample prepared in this example shows that it is the Bi of orthorhombic system through XRD analysis. 2 WO 6 structure, and found that its crystallinity is higher, such as figure 1As shown in c, the sample is mainly composed of microspherical particles. Under simulated sunlight irradiation, the photocatalytic degradation efficiency of rhodamine B can reach 100% after 60 minutes of reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

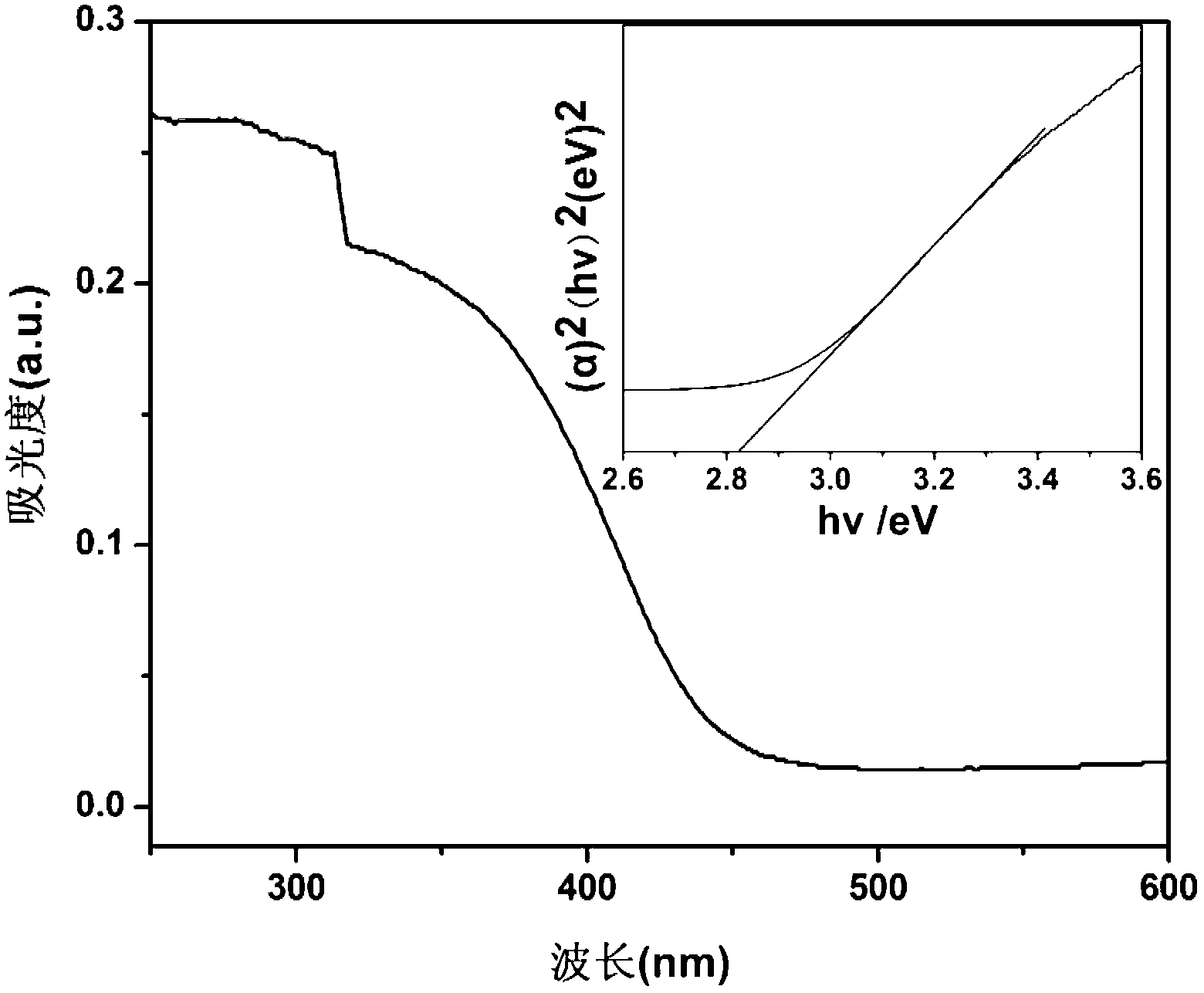

| Band gap energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com