Wet-chemical preparation method for silver micro/nanowires

A nanowire and silver microtechnology, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of the difference in NaOH solution addition, product morphology, complex reaction process, and inconvenient operation. , to achieve the effect of broad industrialization prospects, simple operation and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

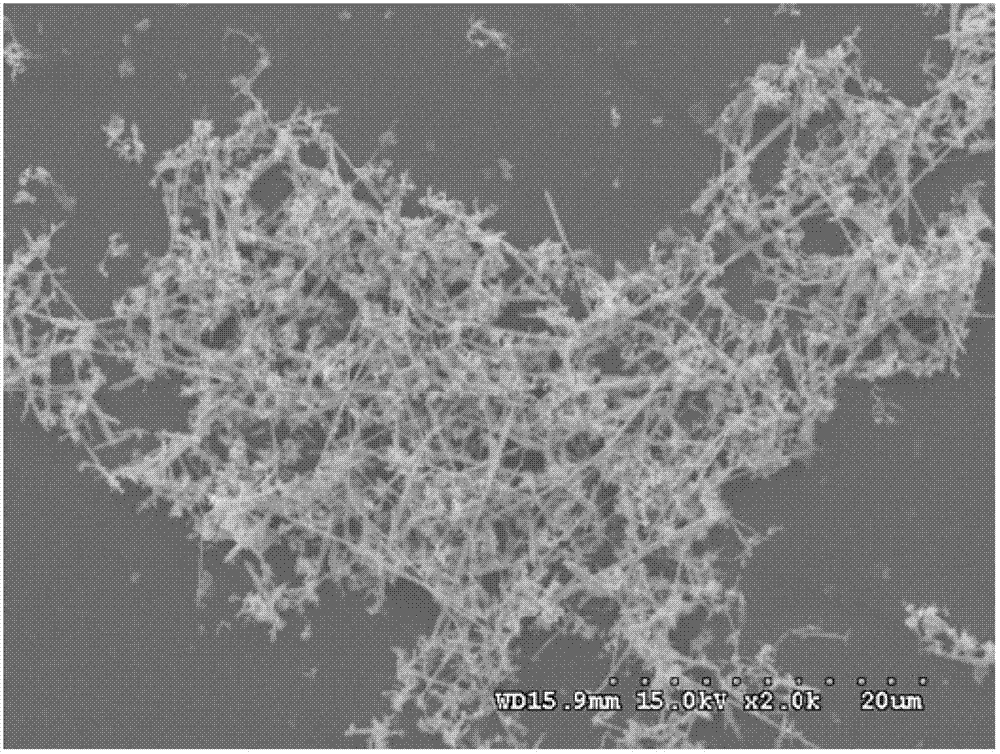

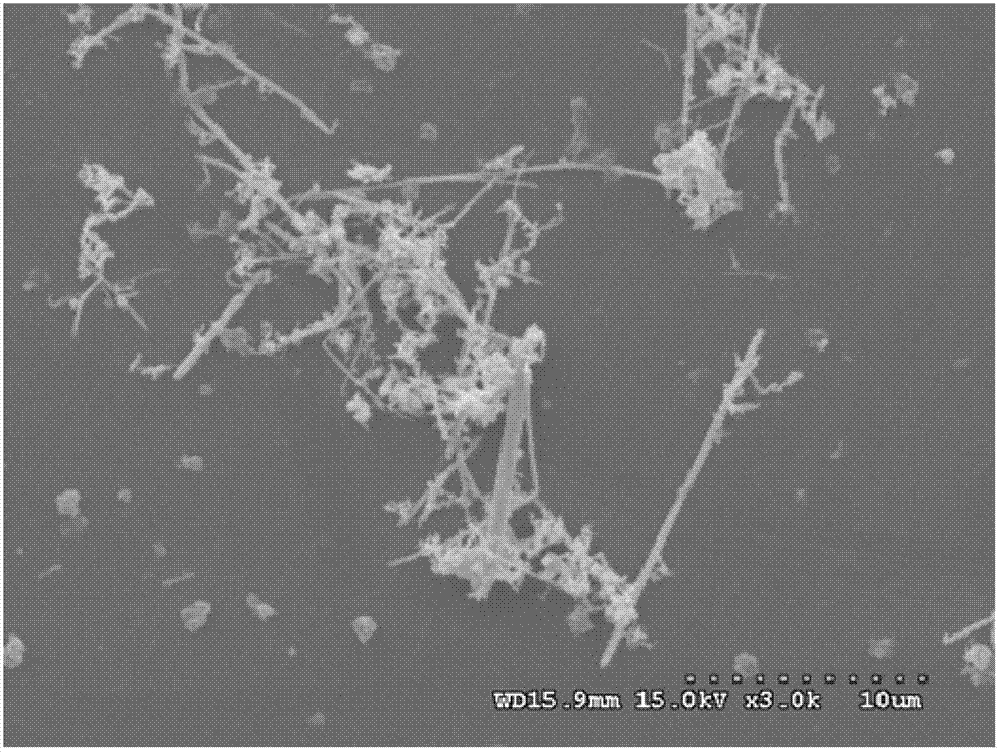

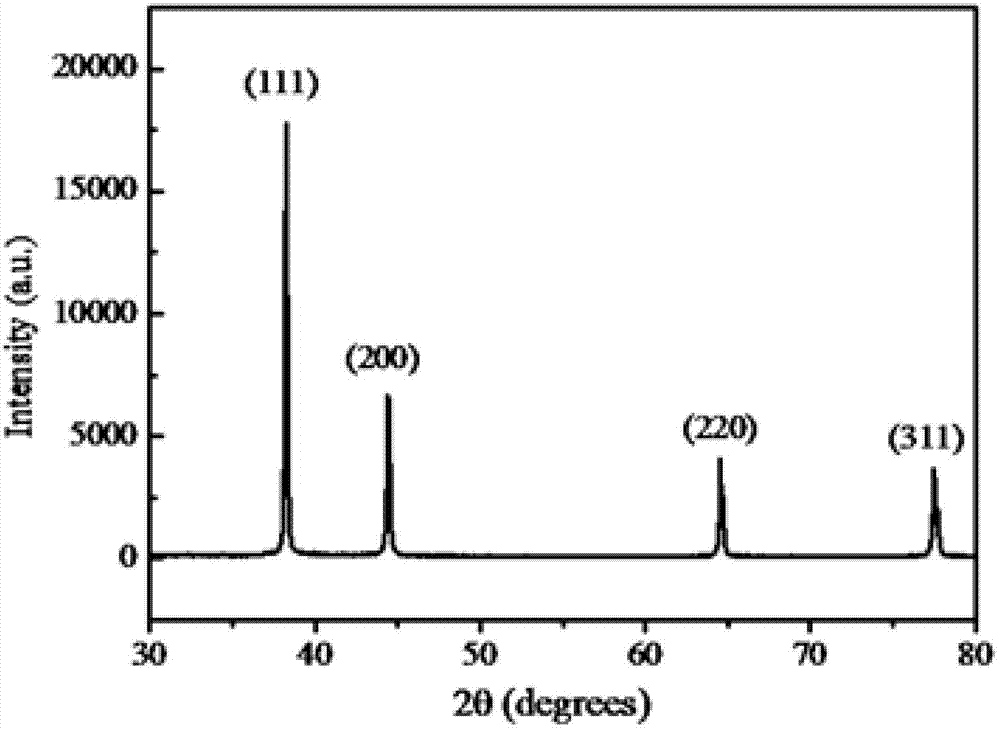

[0056] Dissolve 21 mg of silver nitrate and 50 mg of ferrous sulfate in 10 mL of deionized water respectively, and dissolve 19.2 mg of citric acid in 3 mL of deionized water to prepare a citric acid solution. After adding the citric acid solution to the silver nitrate solution, heat the mixed solution to keep it at 50°C, then add 8 mL of ferrous sulfate solution dropwise to the mixed solution, and after the addition is completed in 30 minutes (dropping rate 0.33 mL / min), centrifuged to separate the precipitate, washed several times with deionized water, washed 2-3 times with absolute ethanol, and finally dried in vacuum to obtain silver micro / nanowires. figure 1 It is the SEM figure enlarged 2000 times for the silver micro / nanowire obtained in Example 1; figure 2 It is a 3000 times enlarged SEM image of the silver micro / nano wire obtained in Example 1; image 3 It is the XRD figure of the silver micro / nanowire obtained in Example 1.

Embodiment 2

[0058] Dissolve 10.5 mg of silver nitrate and 50 mg of ferrous sulfate in 10 mL of deionized water, and dissolve 19.2 mg of citric acid in 3 mL of deionized water to prepare a citric acid solution. After adding the citric acid solution to the silver nitrate solution, heat the mixed solution to keep it at 50°C, then add 5mL ferrous sulfate solution dropwise to the mixed solution, after the dropwise addition is completed within 30 minutes, centrifuge to separate the precipitate, and use After washing with deionized water for several times, washing with absolute ethanol for 2-3 times, and finally vacuum drying to obtain silver micro-wires. Figure 4 It is the SEM picture enlarged 2000 times for the silver micro / nanowire obtained in Example 2.

Embodiment 3

[0060] Dissolve 30 mg of silver nitrate and 100 mg of ferrous sulfate in 10 mL of deionized water respectively, and dissolve 32 mg of citric acid and 10 mg of disodium citrate in 3 mL of deionized water to prepare a citric acid solution. After adding the citric acid solution to the silver nitrate solution, heat the mixed solution to keep it at 60°C, then add 5mL ferrous sulfate solution dropwise to the mixed solution, after the dropwise addition is completed within 30 minutes, centrifuge to separate the precipitate, and use After washing with deionized water for several times, washing with absolute ethanol for 2-3 times, and finally vacuum drying to obtain silver micro-wires. Figure 5 It is the SEM picture enlarged 2000 times for the silver micro / nanowire obtained in Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com