Initial positioning and anti-collision device of plasma cutter

A technology of plasma cutting machine and anti-collision device, applied in the direction of plasma welding equipment, auxiliary equipment, welding/cutting auxiliary equipment, etc., can solve the problems of nylon tube melting, affecting work efficiency, and high maintenance rate, and achieves high use efficiency and structure. Simple and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

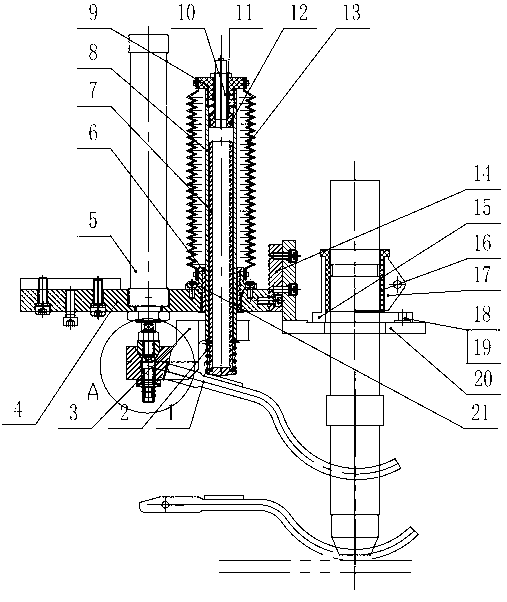

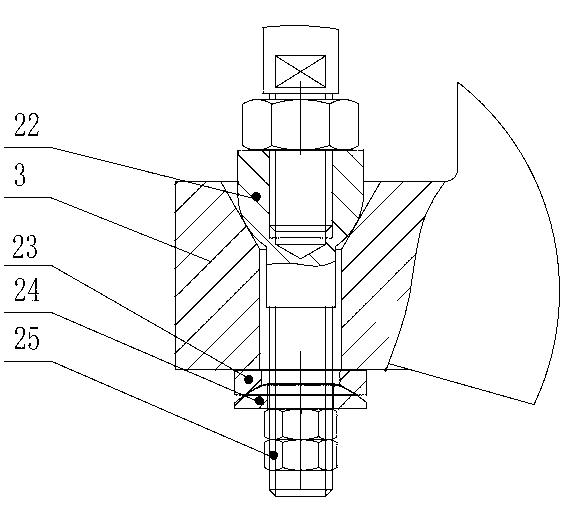

[0016] Such as figure 1 As shown, the cylinder 5 of the present invention is vertically fixed on the mounting plate 4, the connecting frame 3 is a Z-shaped step structure, the piston rod of the cylinder 5 is connected to the bottom of the connecting frame 3, and one end of the detection rod 1 is also hinged on the bottom of the connecting frame 3, The upper part of the connecting frame 3 is connected to the bottom end of the telescopic rod 8, the sensing rod 7 penetrates from the bottom of the telescopic rod 8, the head is supported by the detecting rod 1, and the spring 2 is compressed and installed on the head step of the sensing rod 7 and the connecting frame 3 between. The fixed ring 21 is installed on the mounting plate 4, the copper sleeve 6 is fixed in the fixed ring 21 and the mounting plate 4 holes, the telescopic rod 8 can move up and down in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com