Continuous preparation method for high-purity hydrogen peroxide

A hydrogen peroxide, high-purity technology, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, etc., can solve the problem of increasing production costs and prices of enterprises Expensive and other problems, to achieve the effect of small equipment investment, low production cost and simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

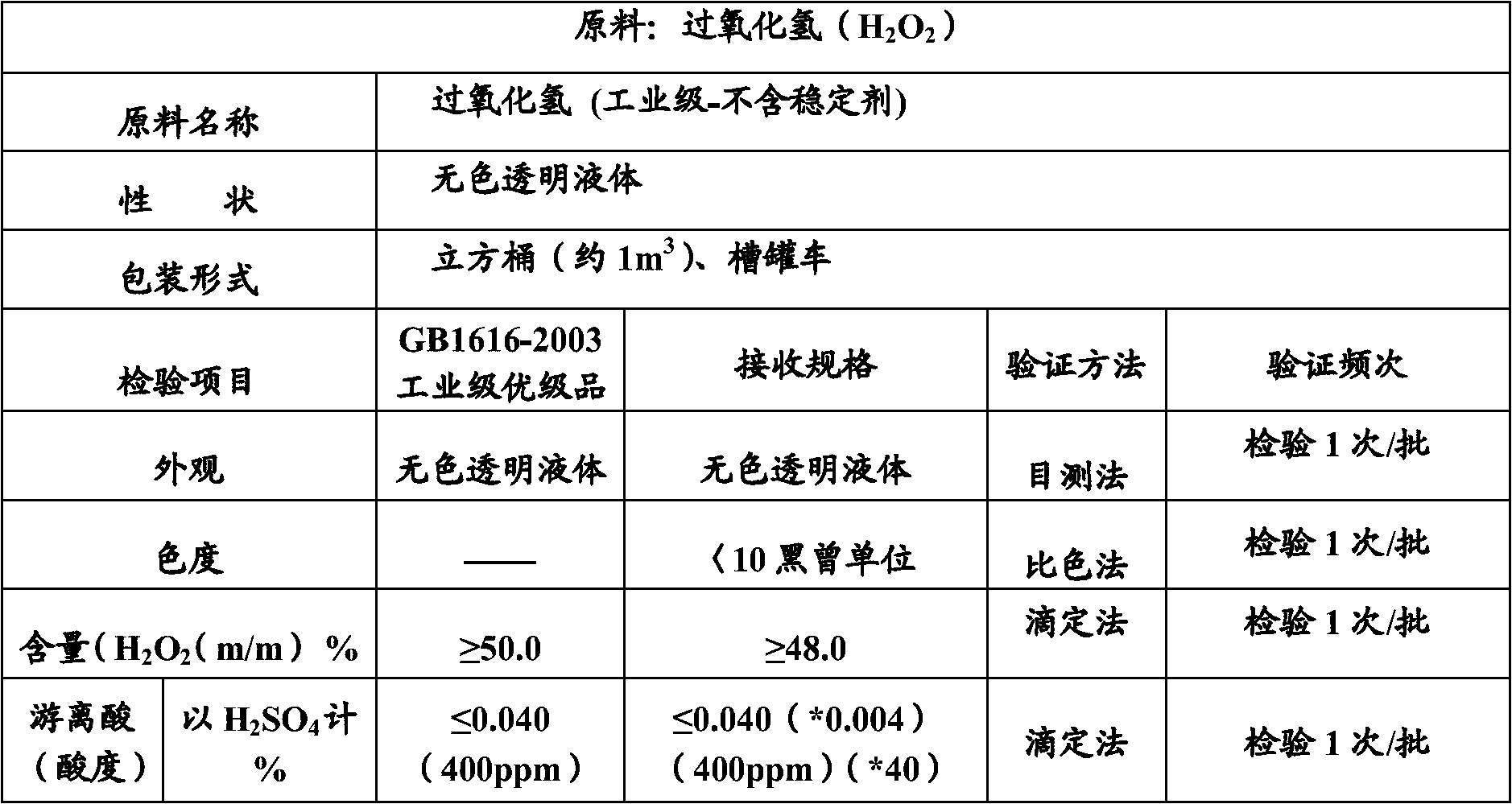

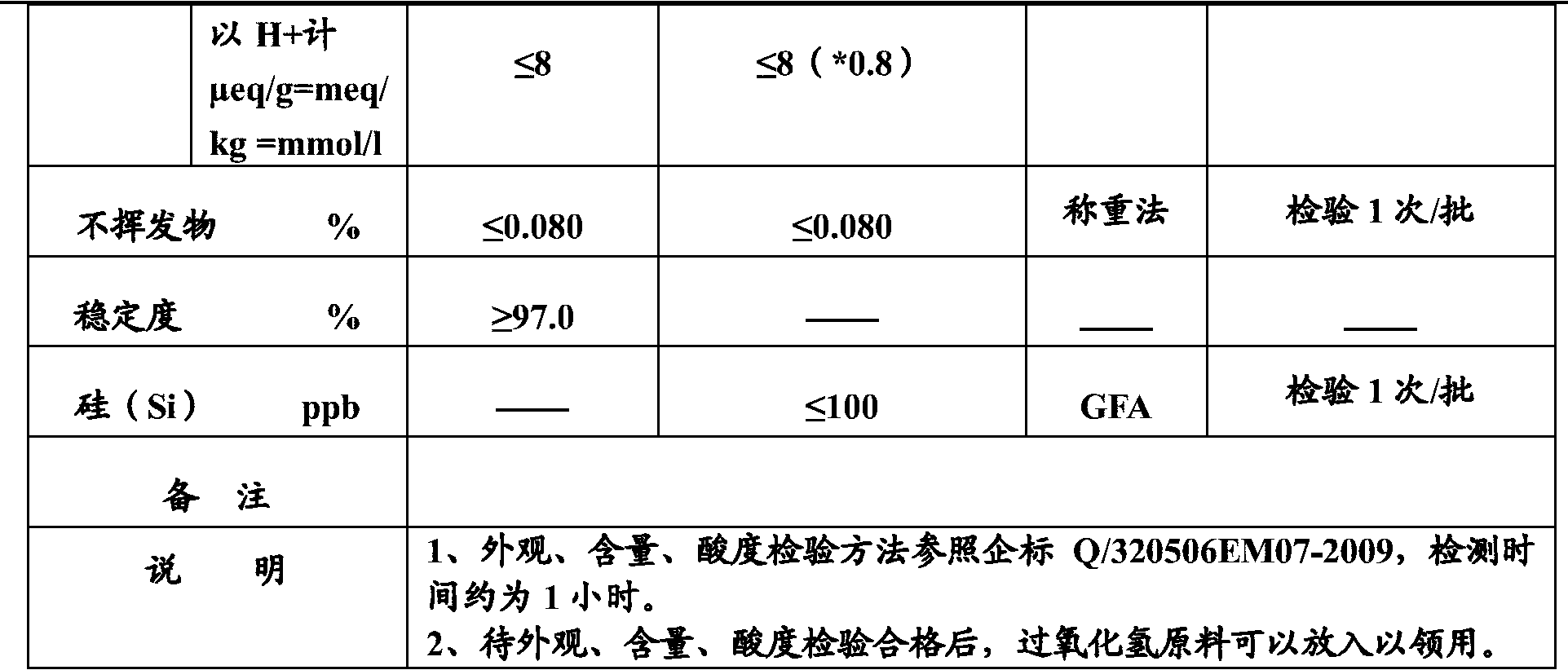

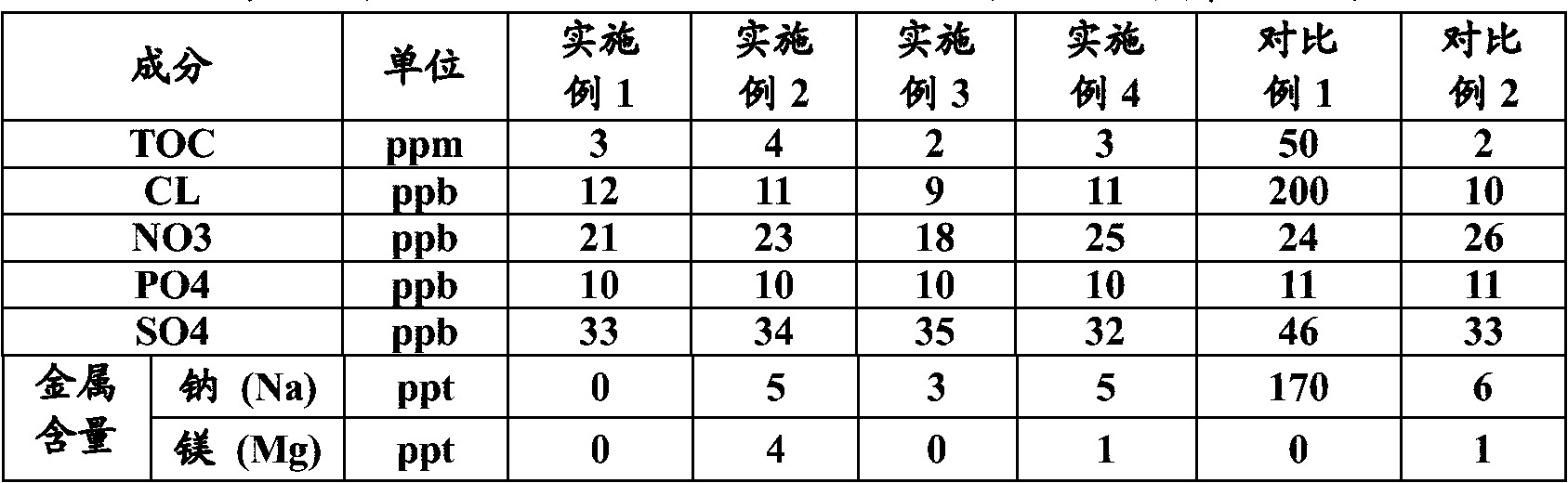

[0028] This embodiment provides a method for preparing high-purity hydrogen peroxide, comprising the following steps carried out sequentially and continuously:

[0029] (1), adjust hydrogen peroxide concentration to 30wt%, and control the temperature of hydrogen peroxide between 0~5 ℃;

[0030](2), make the hydrogen peroxide pass through the macroporous adsorption resin adsorption column (AB series macroporous adsorption resin of Anhui Bengbu Tianxing Resin Company), the cation exchange column (styrene series cation exchange resin 732) and the anion exchange column with the flow rate of 300L / H successively (Styrenic Weak Base Ion Exchange Resin D354), with 0.1 micron filter element circulation filtration, obtain primary purified hydrogen peroxide;

[0031] (3), make the primary purified hydrogen peroxide obtained in step (2) pass through nanofiltration membrane (Dow FILMTEC NF200-400 nanofiltration membrane) and borosilicate resin adsorption column (Shanghai Anlande Biotechnol...

Embodiment 2

[0034] This embodiment provides a method for preparing high-purity hydrogen peroxide, comprising the following steps carried out sequentially and continuously:

[0035] (1), adjust hydrogen peroxide concentration to 40wt%, and control the temperature of hydrogen peroxide between 5~10 ℃;

[0036] (2) Make the hydrogen peroxide pass through the macroporous adsorption resin adsorption column (AB series macroporous adsorption resin of Anhui Bengbu Tianxing Resin Co., Ltd.), the cation exchange column (styrene series cation exchange resin 732) and the anion exchange column successively at a flow rate of 350 L / H (Styrenic Weak Base Ion Exchange Resin D354), with 0.1 micron filter element circulation filtration, obtain primary purified hydrogen peroxide;

[0037] (3), make the primary purified hydrogen peroxide obtained in step (2) pass through nanofiltration membrane (Dow FILMTEC NF200-400 nanofiltration membrane) and borosilicate resin adsorption column (Shanghai Anlande Biotechnol...

Embodiment 3

[0040] This embodiment provides a method for preparing high-purity hydrogen peroxide, comprising the following steps carried out sequentially and continuously:

[0041] (1), adjust hydrogen peroxide concentration to 40wt%, and control the temperature of hydrogen peroxide between 0~15 ℃;

[0042] (2) Make the hydrogen peroxide pass through the macroporous adsorption resin adsorption column (YWD series macroporous adsorption resin of Cangzhou Yuanwei Chemical Co., Ltd.), the cation exchange column (Strong Acid No. 1) and the anion exchange column (styrene After being weak base ion exchange resin D370), circulate and filter with a 0.1 micron filter element to obtain primary purified hydrogen peroxide;

[0043] (3), the primary purified hydrogen peroxide obtained in step (2) passes through nanofiltration membrane (Dow FILMTEC NF200-400 nanofiltration membrane), borosilicate resin adsorption column (Rohm and Haas amberliter tm PWa10 series) successively with the flow rate of 400L / H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com