Magnetic activated sludge reactor and method for realizing short-cut denitrification

A technology of activated sludge and reaction device, which is applied in the field of magnetic activated sludge reactor and its realization of biological short-range denitrification, which can solve the problems of insufficient carbon source for denitrification, low carbon-to-nitrogen ratio, and low sludge yield. Achieve the effect of reducing sludge treatment and disposal costs, large volume load and low sludge yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment describe the patent of the present invention in detail:

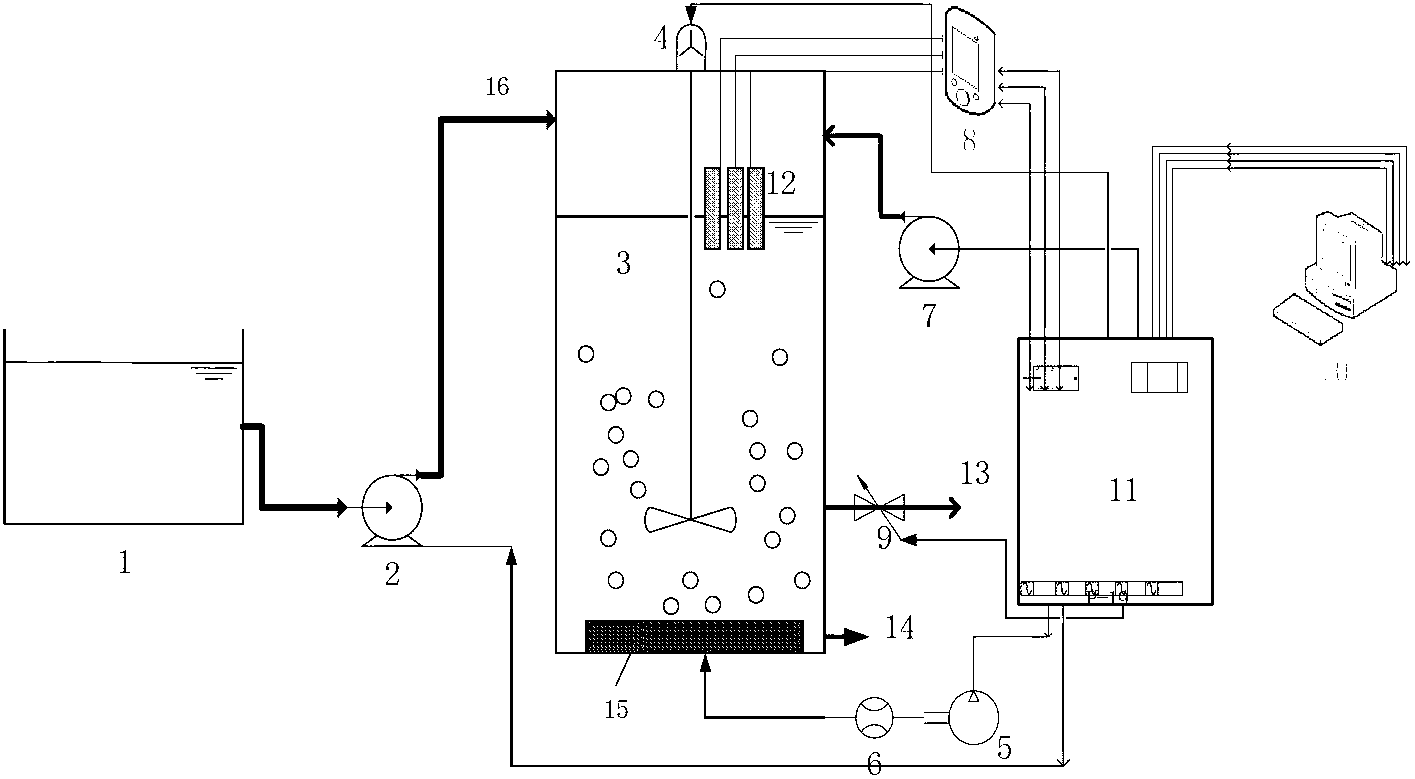

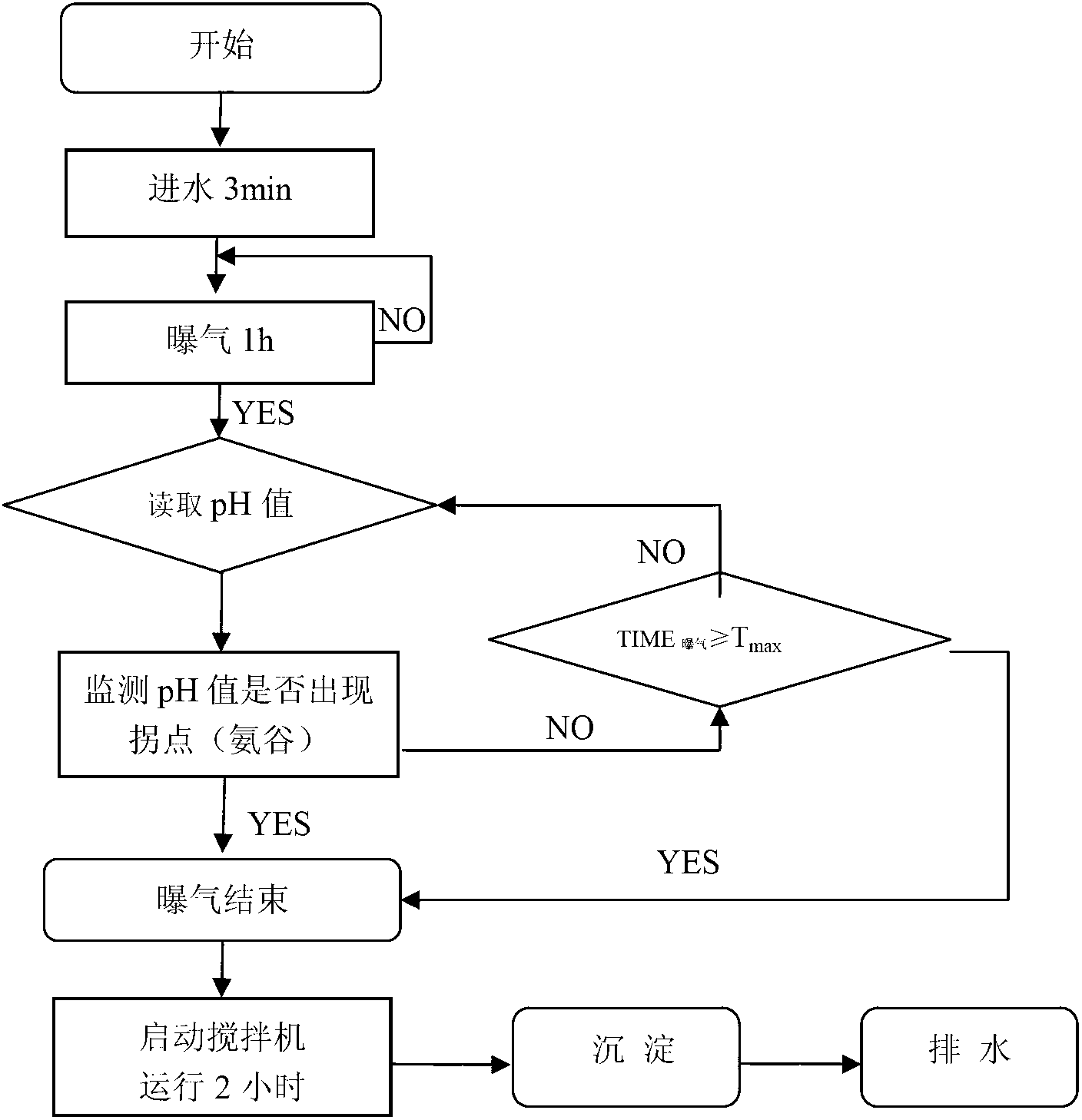

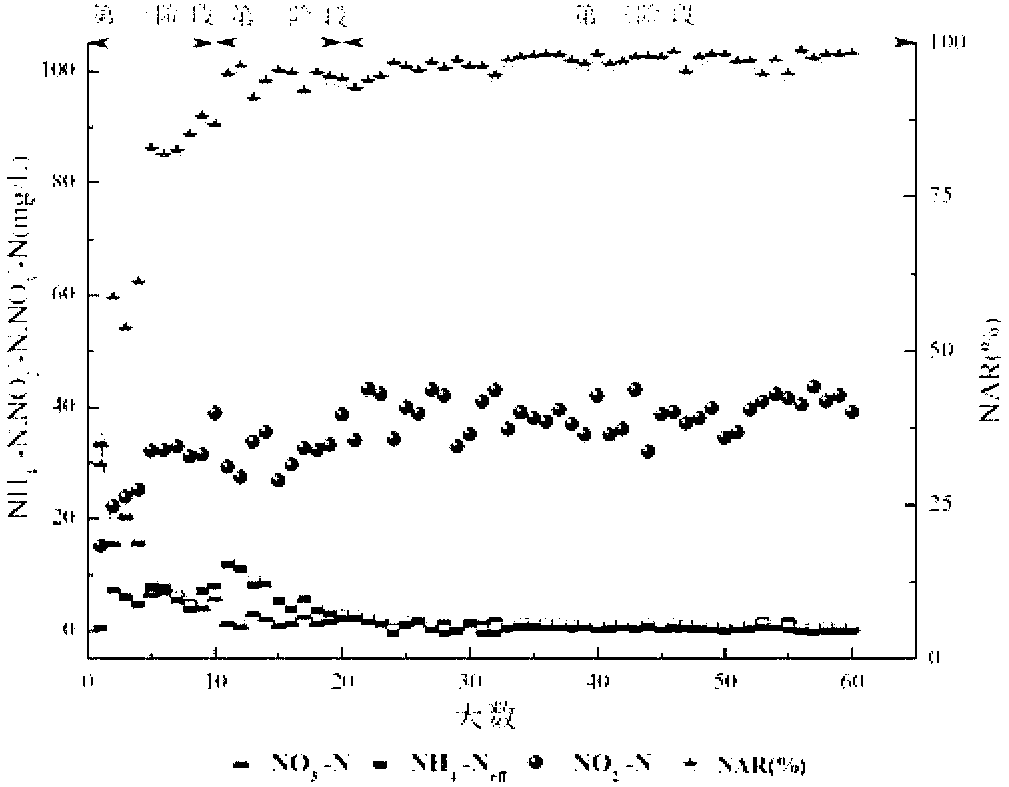

[0027]Taking the septic tank effluent of a teaching staff living area in a university in Beijing as the treatment object, the influent COD=200mg / L~465mg / L, ammonia nitrogen=80mg / L~100mg / L, pH=7.0~7.8, nitrite nitrogen=0.1mg / L L~0.5mg / L, nitrate nitrogen=0.2mg / L~1.8mg / L, reactor sludge concentration MLSS is 10000mg / L~13000mg / L, sludge age is more than 60 days, plus carbon source sodium acetate, the operation results : At the end of aeration, the average ammonia nitrogen is 0.8mg / L, the average effluent COD is 38.5mg / L, and the average effluent TN is 2.5mg / L. figure 1 , image 3 , Figure 4 shown. Specific steps are as follows:

[0028] Step 1. The effective volume of the water inlet magnetic activated sludge reactor is 85L, and the water inlet is 60L. First, the computer sends an instruction to the PID controller, and the water inlet pump and the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com