Method for treating fly ash

A treatment method and technology for fly ash, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve the effect of reducing creep, saving cement and fine aggregate, and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0013] First prepare an active solution, which contains one or more of the following components: Na2CO3, Na2O: SiO2, Na2O: Al2O3, NaOH. The active solution is mixed in a leak-proof HDPE (high-density polyethylene) bottle. Pour the components into a bottle and add a certain amount of water. Shake in hand for 10-15 seconds to ensure it is well mixed. In most cases the temperature of the solution will rise, set it aside to cool. (About minutes or hours depending on the components).

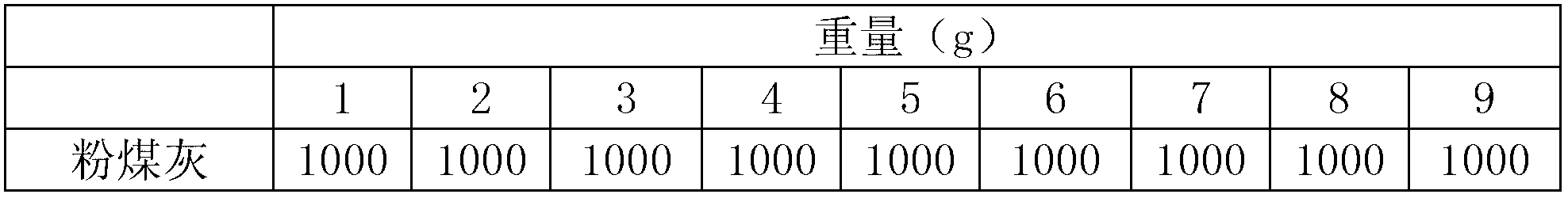

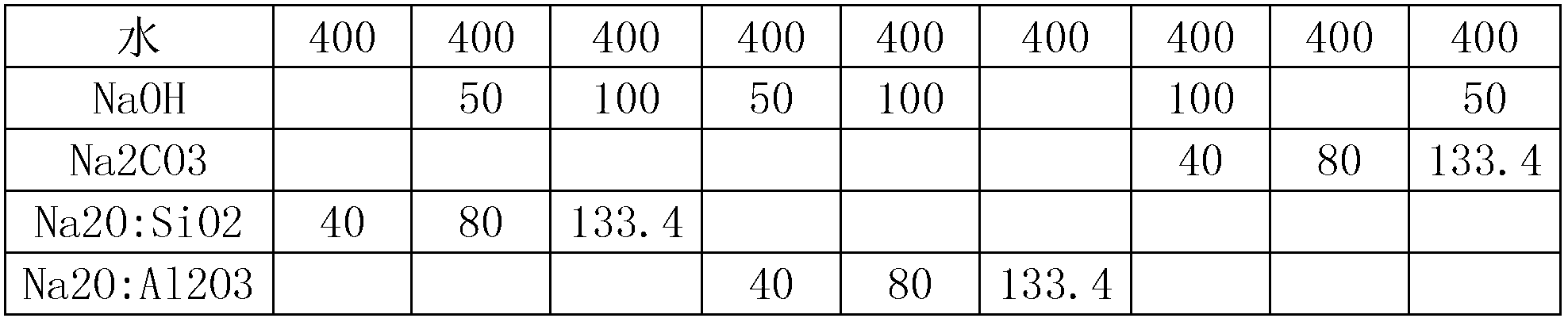

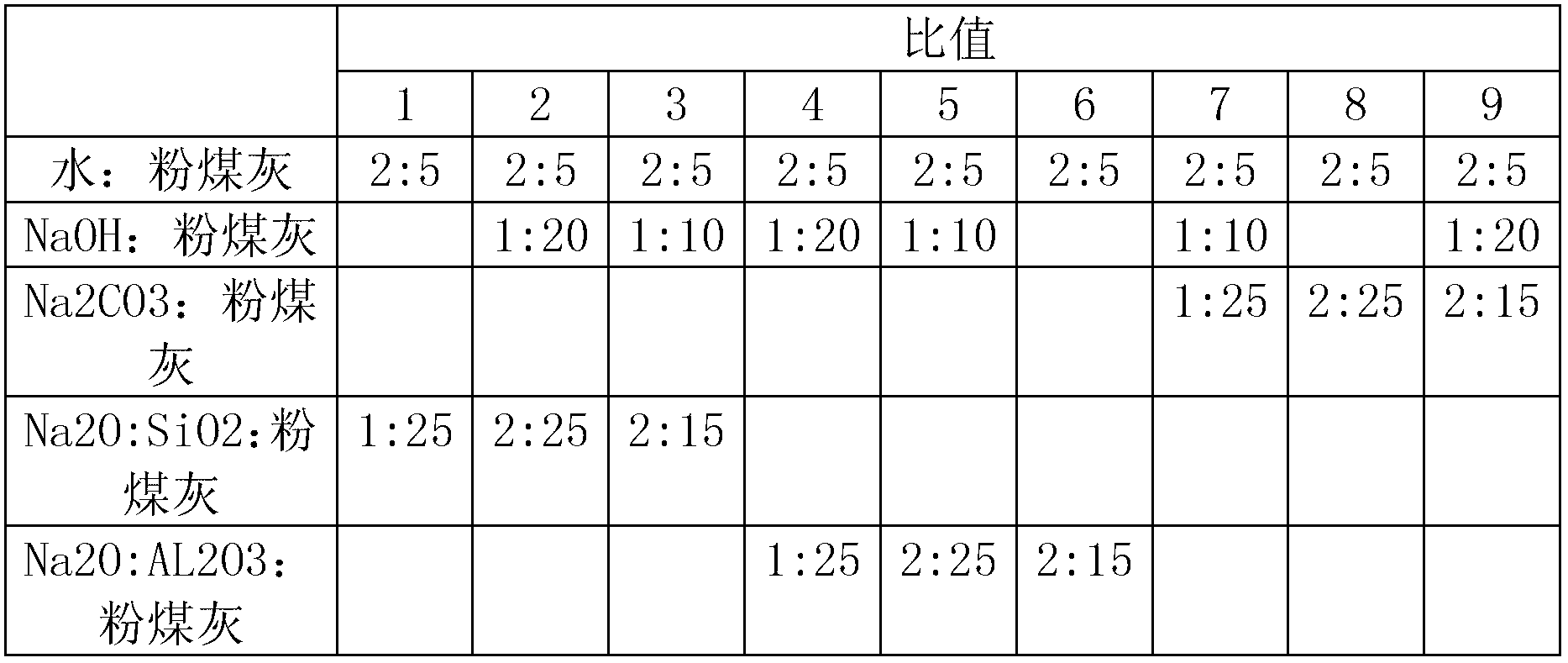

[0014] Mix 1000g of fly ash and a small amount of ADVA (plasticizer). Then pour it into the bottle and mix with the active solution and shake for 5 minutes. The composition of the active solution is shown in Table 1 and Table 2.

[0015] Table 1

[0016]

[0017]

[0018]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com