Foam filling body for coal mine goaf filling and preparation filling method of foam filling body

A goaf and foam technology, applied in applications, household appliances, ceramic products, etc., can solve the problems of increasing the unit price of coal per ton, large amount of cement, etc., and achieve the effect of significant economic benefits, increased consumption, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

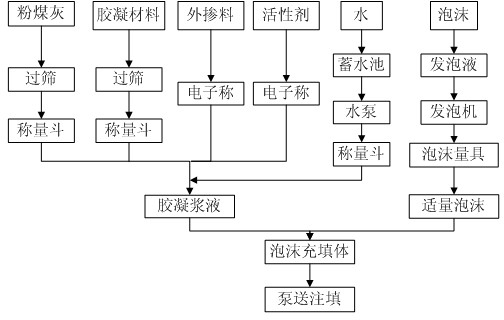

[0023] The method and effect of the present invention will be further described in detail below in conjunction with the accompanying drawings and an embodiment of the present invention, but the present invention is not limited to this embodiment.

[0024] (1) Raw materials and components by weight: 65 parts of fly ash, 35 parts of cement, 45 parts of water, 0.35 parts of water reducing agent, 0.7 parts of coagulation accelerator, 0 parts of active agent, foam: the percentage of gelled slurry volume is 100%.

[0025] The cement is Portland cement with a strength grade of 32.5 or 42.5, and its performance meets the requirements of GB175-1999 "Portland Cement, Ordinary Portland Cement";

[0026] The fly ash is a third-grade fly ash, and its performance meets the requirements of GB / T1596-2005 "Fly Ash Used in Cement and Concrete";

[0027] The water reducer is a polycarboxylate high-performance water reducer;

[0028] The coagulant is sulfate type;

[0029] The foaming agent i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com