Method for preparing compound fertilizer-conserving nutritional soil from anaerobic fermentation residue

An anaerobic fermentation and residue technology, which is applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of easy compaction of topsoil, poor ventilation and water permeability, and poor slow release effect of nutrient soil, and achieves good fertilizer retention. The effect of easy compaction, reduction of the number of fertilization and watering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

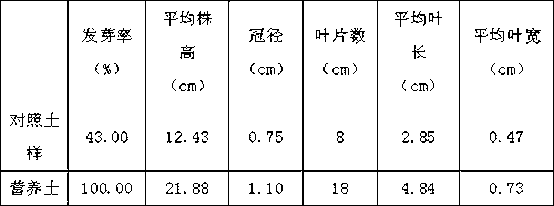

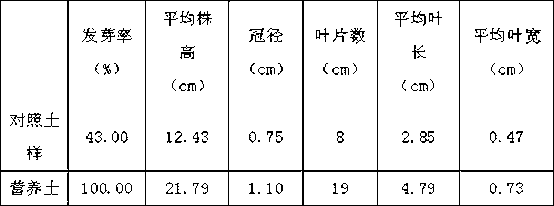

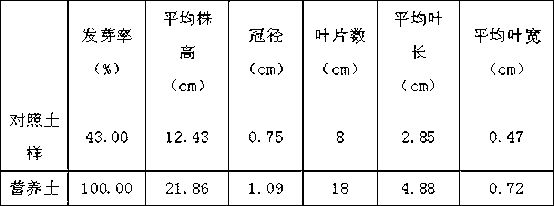

Embodiment 1

[0024] Embodiment 1: prepare the method for compound fertilizer-preserving nutrient soil with anaerobic fermentation residue, concrete operations are as follows:

[0025] (1) Add 2kg of dimercaptopropanol and 1.5kg of masking agent dimercaptopropanol and 1.5kg of tartaric acid to 100L of landfill landfill in the western suburbs of Kunming. Adsorption, the adsorption time is 48h, the adsorbent is taken out and air-dried at room temperature for later use;

[0026] (2) Ferment livestock and poultry manure and corn stalks (mixing ratio 2:1) for 40 days, the fermentation temperature is medium temperature 35°C, the fermentation state is ordinary wet fermentation, and the solid residue after fermentation is air-dried to obtain biogas residue, fermentation liquid Biogas slurry is produced from phase residue;

[0027] (3) Mix 5.4kg of diatomite with 2kg of biogas residue, 0.1kg of ammonium sulfate, 2kg of surface soil, and 0.5kg of biogas slurry, and air-dry it at room temperature unt...

Embodiment 2

[0036] Embodiment 2: prepare the method for compound fertilizer-preserving nutrient soil with anaerobic fermentation residue, concrete operations are as follows:

[0037] (1) Add 4kg of masking agent hydroxylamine hydrochloride to 100L of landfill leachate in the western suburbs of Kunming. After 10mim of treatment, take 3.5kg of diatomaceous earth to adsorb the treated landfill leachate at room temperature for 36 hours. , take out the adsorbent and air-dry it at room temperature for later use;

[0038] (2) Ferment the manure of livestock and poultry for 40 days, the fermentation temperature is medium temperature 37°C, the fermentation state is ordinary wet fermentation, the solid residue after fermentation is air-dried to obtain biogas residue, and the residue of fermentation liquid phase is obtained to obtain biogas slurry;

[0039] (3) Mix 3.5kg of diatomaceous earth with 3.5kg of biogas residue, 0.2kg of potassium chloride, 2kg of surface soil, and 0.8kg of biogas slurry, ...

Embodiment 3

[0043] Embodiment 3: prepare the method for compound fertilizer preserving nutrient soil with anaerobic fermentation residue, concrete operation is as follows:

[0044] (1) Take 100L of landfill leachate in the western suburbs of Kunming and add 5kg of masking agent tartaric acid. After 5mim is treated, take 4kg of diatomaceous earth to adsorb the treated landfill leachate at room temperature for 40 hours. Take out The adsorbent was air-dried at room temperature for later use;

[0045] (2) Ferment corn stalks for 40 days, the fermentation temperature is 33°C, and the fermentation state is ordinary wet fermentation. After the fermentation, the solid residue is air-dried to obtain biogas residue, and the fermentation liquid phase residue is obtained to obtain biogas slurry;

[0046] (3) Mix 4 kg of diatomite with 2 kg of biogas residue, 0.15 kg of superphosphate, 2.5 kg of surface soil, and 1.35 kg of biogas slurry, and air-dry it at room temperature until the particle size is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com