Technology for directly producing halogenated butyl rubber using butyl glue prepared by solution method

A technology of halogenated butyl rubber and butyl rubber, which is applied in the field of direct production of halogenated butyl rubber from butyl glue solution by solution method, which can solve the problems of inability to prepare uniform and stable halogenated butyl rubber, processing difficulties, and degradation of butyl rubber, etc. problems, to avoid solvent switching, improve co-vulcanization, and increase reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

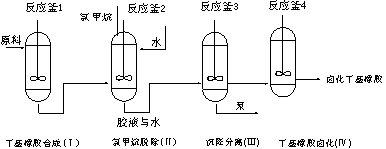

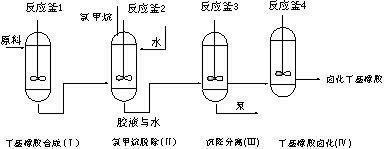

Method used

Image

Examples

Embodiment 1

[0022] At -100°C, add hexane and methyl chloride to the reaction kettle to form a mixed solvent (hexane 160mL, methyl chloride 72mL), the mass ratio of methyl chloride to hexane is 38:62; mix well and then add 140mL to the solvent Isobutene and isoprene, the mass ratio of isobutene and isoprene is 97:3. The monomer concentration is 36wt%. The molar ratio of sesquiethylaluminum chloride (0.0036mol / L) is 1:3, and the initiator system is added to the polymerization kettle to initiate polymerization, and the polymerization is carried out for 30 minutes to obtain butyl rubber glue. The molecular weight of butyl rubber is determined to be 500 , 000g / mol, the molecular weight distribution is 1.9, and the isoprene content is 2.0mol%. After entering reactor 3 to settle for 100 minutes, enter reactor 4 after extracting the water layer with a pump, remove monochloromethane, unreacted isobutylene and part of hexane, and the glue concentration is 65 wt%. Add hexane, glue The liquid concen...

Embodiment 2

[0024] At -80°C, add hexane and methyl chloride to the reaction kettle to form a mixed solvent (hexane 120mL, methyl chloride 90mL), the mass ratio of methyl chloride to hexane is 50:50; mix well and then add 155mL to the solvent Isobutylene and isoprene, the mass ratio of isobutylene and isoprene is 98:2. The monomer concentration is 45wt%. The initiator system consists of cumyl chloride, ethyl aluminum dichloride and formamide, and the cumyl chloride is 0.01mol / L, ethylaluminum dichloride is 0.24mol / L, and formamide is 0.01mol / L. The molar ratio of water: formamide: ethyl aluminum dichloride is 1:1:24. Add an initiator system to the polymerization kettle to initiate polymerization, and polymerize for 60 minutes to obtain butyl rubber glue. The molecular weight of butyl rubber is determined to be 55 , 000g / mol, the molecular weight distribution is 1.9, and the isoprene content is 1.5mol%. After entering reactor 3 to settle for 180 minutes, enter reactor 4 after extracting t...

Embodiment 3

[0026] At -50°C, add hexane and methyl chloride to the reaction kettle to form a mixed solvent (hexane 160mL, methyl chloride 30mL), the mass ratio of methyl chloride to hexane is 20:80; mix well and then add 35mL to the solvent Isobutene and isoprene, the mass ratio of isobutene and isoprene is 85:15. The monomer concentration is 15wt%. The initiator system consists of dicumyl chloride, aluminum trichloride and acetone, and the content of dicumyl chloride is 0.01mol / L, aluminum trichloride is 0.6mol / L, and acetone is 0.1mol / L. Dicumyl chloride: acetone: the molar ratio of aluminum trichloride is 1:10:60. Add initiating system in polymerization kettle and initiate polymerization, polymerization 60 minutes, obtain butyl rubber glue, the molecular weight of butyl rubber after measuring is 10,000g / mol, the molecular weight distribution is 1.9, and the isoprene content is 10mol%. After entering reactor 3 to settle for 80 minutes, enter reactor 4 after extracting the water layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com