Direct addition type rubber powder composite asphalt mixture modifier and preparation method thereof

A technology of composite asphalt and mixture, which can be used in building thermal insulation materials, building components, buildings, etc., and can solve the problem of difficulty in recycling waste polymers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

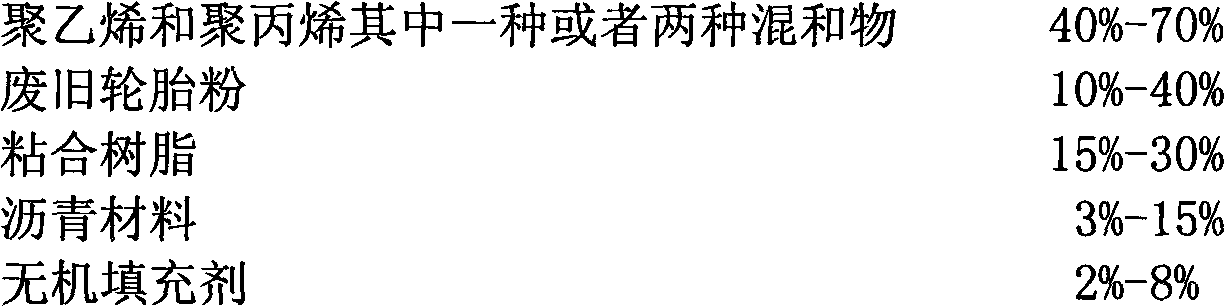

Embodiment 1

[0021] Mix 20% of 20-mesh waste rubber powder and 57% polyethylene in a high-speed mixer, then add 5% of natural asphalt and 15% of petroleum resin, and continue to mix evenly; finally add 3% of calcium carbonate, mix The homogeneous material is put into a twin-screw extruder, heated to 140-180°C to form a molten mixture and then extruded; during the water cooling process, it is kept in an environment of 120-140°C to pelletize to obtain a finished product.

Embodiment 2

[0023] Mix 20% of 40-mesh waste rubber powder and 57% polyethylene in a high-speed mixer, then add 5% of natural asphalt and 15% of petroleum resin, and continue to mix evenly; finally add 3% of calcium carbonate, mix The homogeneous material is put into a twin-screw extruder, heated to 140-180°C to form a molten mixture and then extruded; during the water cooling process, it is kept in an environment of 120-140°C to pelletize to obtain a finished product.

Embodiment 3

[0025] Mix 20% of 80-mesh waste rubber powder and 57% polyethylene in a high-speed mixer, then add 5% of natural asphalt and 15% of petroleum resin, and continue to mix evenly; finally add 3% of calcium carbonate, mix The homogeneous material is put into a twin-screw extruder, heated to 140-180°C to form a molten mixture and then extruded; during the water cooling process, it is kept in an environment of 120-140°C to pelletize to obtain a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com