Method for extracting glutamic acid decarboxylase from banana peel and method for producing r-reanal

A technology of glutamic acid decarboxylase and aminobutyric acid, applied in the direction of lyase, fermentation, etc., can solve the problems of long production cycle, high production cost, and difficult separation, and achieve low cost, convenient operation, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

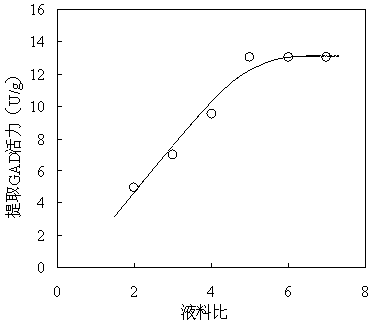

[0035] Use a soybean milk machine to crush 1kg of banana peel until it becomes muddy, so that the fiber and protein are separated. The length of the fiber is 2mm. Put it in a conical flask and add 2L of vitamin B with a pH of 5.5 and 0.1g / L. 6 Phosphate buffer (Na 2 HPO 4 / NaH 2 PO 4 ), shake well, stand for extraction for 4 hours, then centrifuge at 9000 rpm for 10 minutes to obtain crude enzyme solution.

Embodiment 2

[0037] Use a soybean milk machine to crush 1kg of banana peel until it becomes muddy, so that the fiber and protein are separated. The length of the fiber is 2mm. Put it in a triangular flask, add 5L of vitamin B with a pH of 5.5 and 0.1g / L 6 Phosphate buffer (Na 2 HPO 4 / NaH 2 PO 4 ), shake well, stand for extraction for 4 hours, then centrifuge at 9000 rpm for 10 minutes to obtain crude enzyme solution.

Embodiment 3

[0039] Use a soybean milk machine to crush 1kg of banana peel until it becomes muddy, so that the fiber and protein are separated. The length of the fiber is about 2mm. Put it in a conical flask and add 7L of vitamin B with pH5.5 and 0.1g / L 6 Phosphate buffer (Na 2 HPO 4 / NaH 2 PO 4 ), shake well, stand for extraction for 4 hours, then centrifuge at 9000 rpm for 10 minutes to obtain crude enzyme solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com