Polycrystalline silicon furnace

A polysilicon and silicon furnace technology, applied in the field of energy-saving polysilicon furnaces and polysilicon ingot furnaces, can solve the problems of high energy consumption of polysilicon, achieve long service life, good energy-saving effect, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

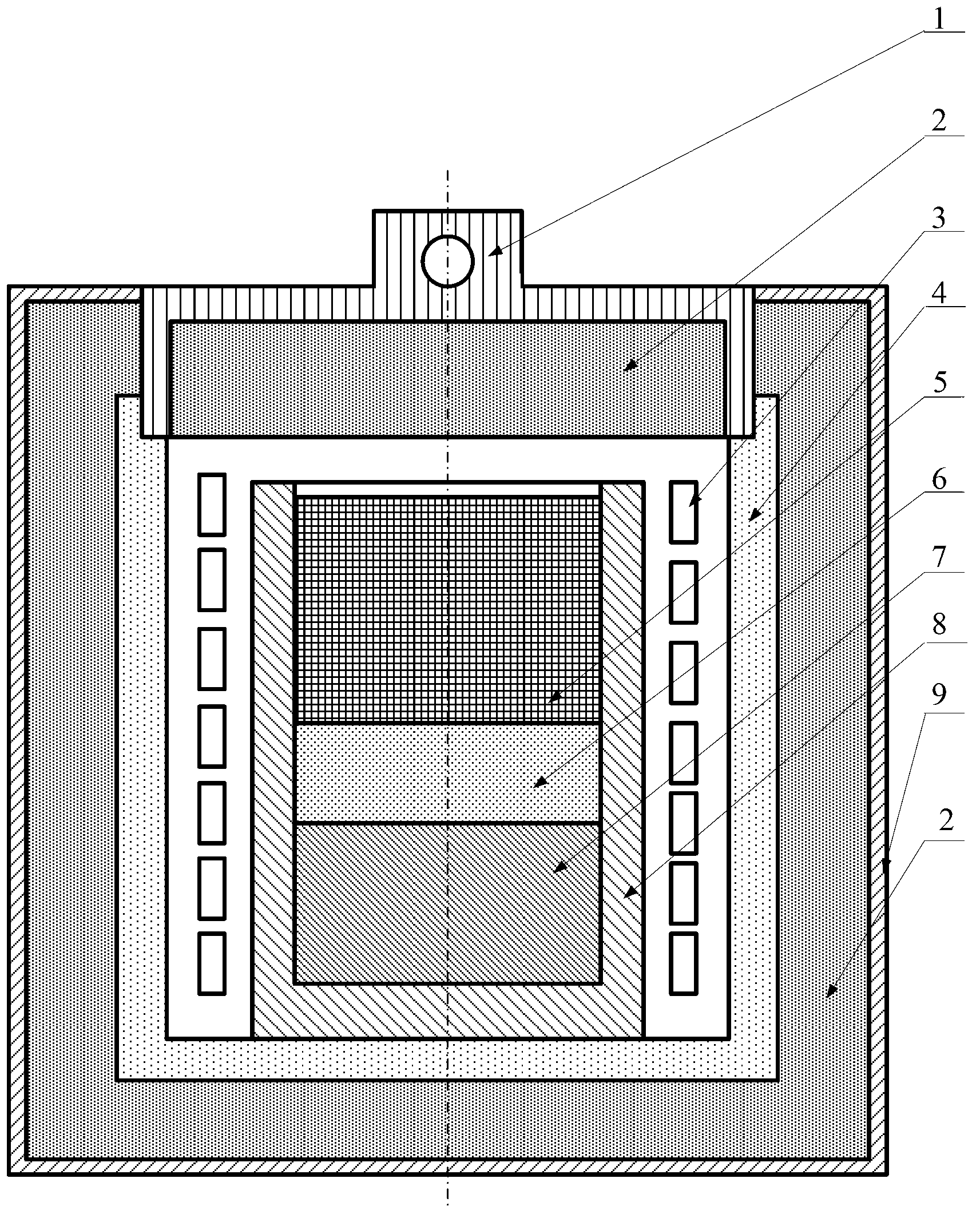

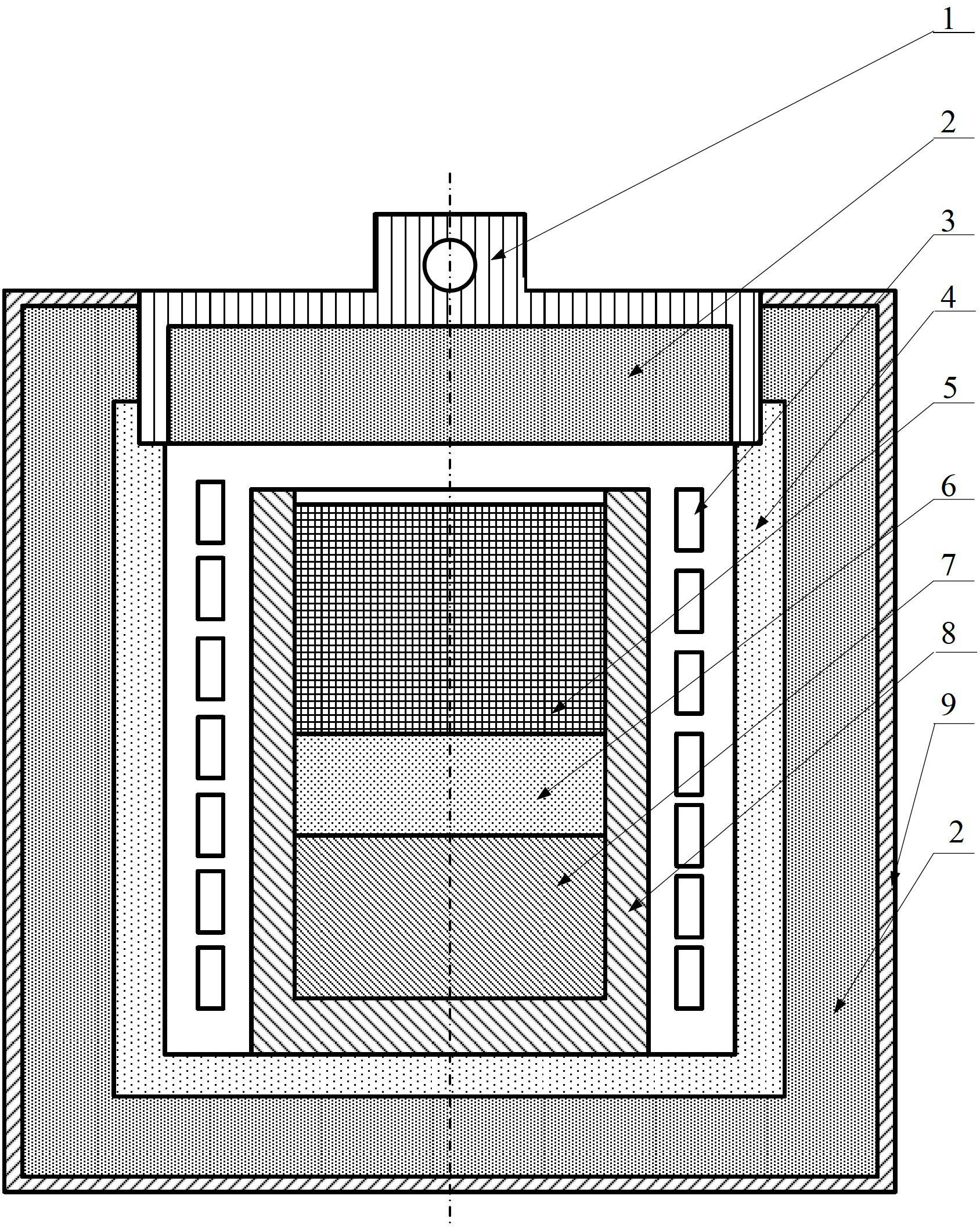

[0020] An energy-saving polysilicon furnace, see figure 1 , consisting of heat-resistant steel 1, potassium hexatitanate whisker insulation brick 2, heating device 3, Al 2 o 3 It is composed of refractory brick 4, crucible 8 and low carbon steel plate 9, etc. The shell of the polysilicon furnace is a Q235 low-carbon steel plate 9 with a thickness of 12mm, and a potassium hexatitanate whisker heat insulation brick 2 is added in the shell. % of silica sol (silica sol grade GRJ-26, see Ministry of Aerospace Standard HB5346-1986) mixed to make heat insulation bricks, and baked at 750 ° C for 3 hours. Add Al with a thickness of 35mm inside the insulation brick 2 2 o 3 refractory brick 4, and place the crucible 8 in the polysilicon furnace, place the heating device 3 (composed of 7 independent heaters) outside the crucible 8, and set a retrieving cover above the polysilicon furnace, the retrieving cover is The potassium hexatitanate whisker insulation brick 2 is embedded in the...

Embodiment 2

[0022] An energy-saving polysilicon furnace that will figure 1 , made of heat-resistant steel, potassium hexatitanate whisker insulation brick, heater, Al 2 o 3 Composed of refractory bricks, crucibles and low carbon steel plates. The shell of the polysilicon furnace is Q235 low-carbon steel plate 9 with a thickness of 15mm, and the potassium hexatitanate whisker heat insulation brick 2 is added in the shell. % of silica sol (silica sol grade GRJ-30, see Ministry of Aerospace Standard HB5346-1986) mixed to make heat insulation bricks, and baked at 800 ° C for 2 hours. Add Al with a thickness of 50mm inside the insulation brick 2 2 o 3 refractory brick 4, and place the crucible 8 in the polysilicon furnace, place the heating device 3 (composed of 8 independent heaters) outside the crucible 8, and set a retrieving cover above the polysilicon furnace, the retrieving cover is The potassium hexatitanate whisker insulation brick 2 is embedded in the heat-resistant steel 1, and ...

Embodiment 3

[0024] An energy-saving polysilicon furnace that will figure 1 Made of heat-resistant steel, potassium hexatitanate whisker insulation brick, heater, Al 2 o 3 Composed of refractory bricks, crucibles and low carbon steel plates. The shell of the polysilicon furnace is Q235 low-carbon steel plate 9 with a thickness of 14mm, and potassium hexatitanate whisker heat insulation brick 2 is added in the shell. % of silica sol (silica sol grade GRJ-26, see Ministry of Aerospace Standard HB5346-1986) mixed to make heat insulation bricks, and baked at 750 ° C for 3 hours. Add Al with a thickness of 40mm inside the insulation brick 2 2 o 3 refractory brick 4, and place the crucible 8 in the polysilicon furnace, place the heating device 3 (composed of 6 independent heaters) outside the crucible 8, and set a retrieving cover above the polysilicon furnace, the retrieving cover is The potassium hexatitanate whisker insulation brick 2 is embedded in the heat-resistant steel 1, and the he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com