Wind-power air compressor

An air compressor and wind power technology, which is applied in the field of horizontal drive wind turbines and wind energy and gas production, can solve the problems of increasing the friction between the piston and the cylinder, increasing the operating load of the convex teeth, and occupying a large space, so as to improve the operation efficiency, Improved discharge pressure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

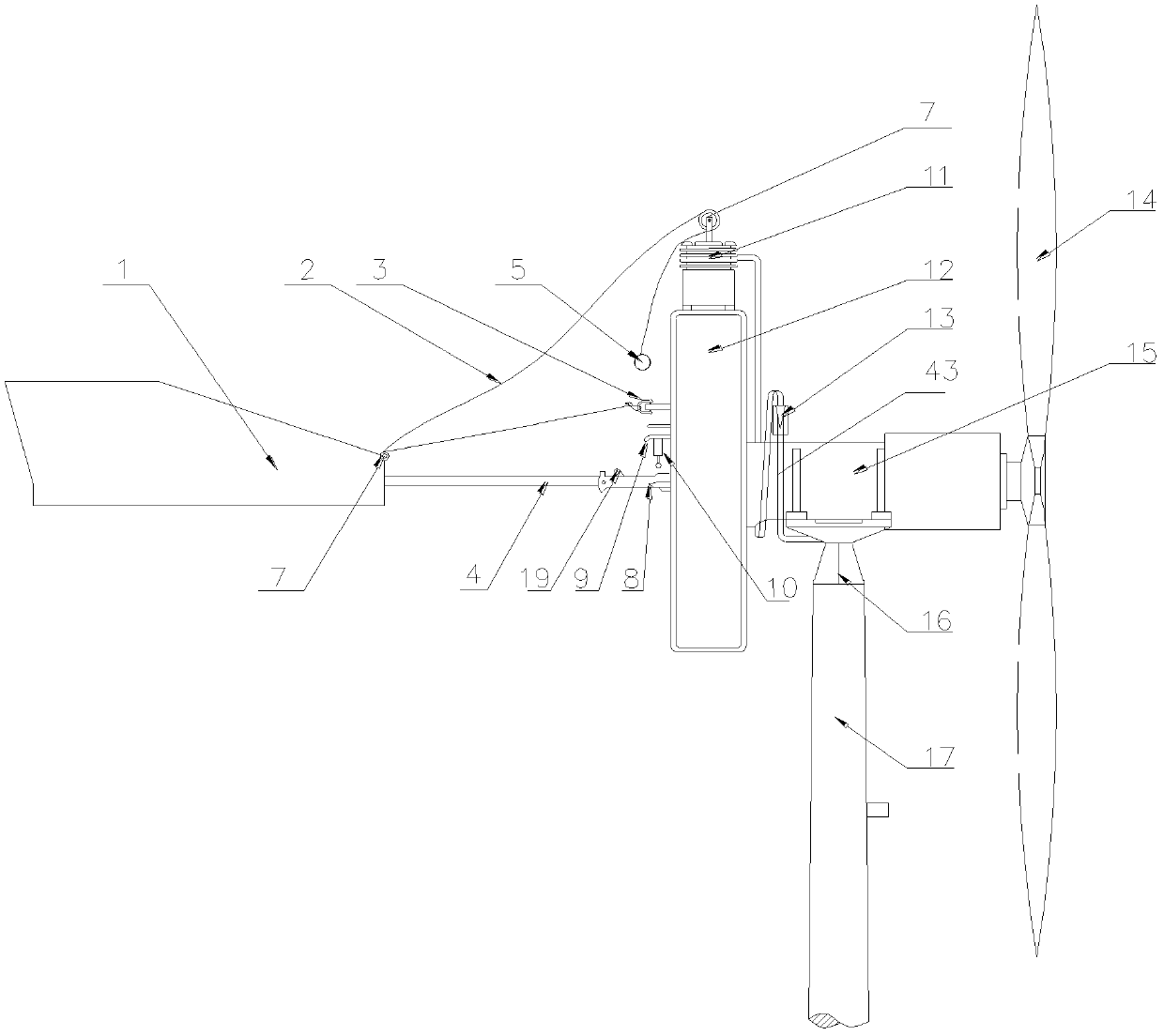

[0090] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

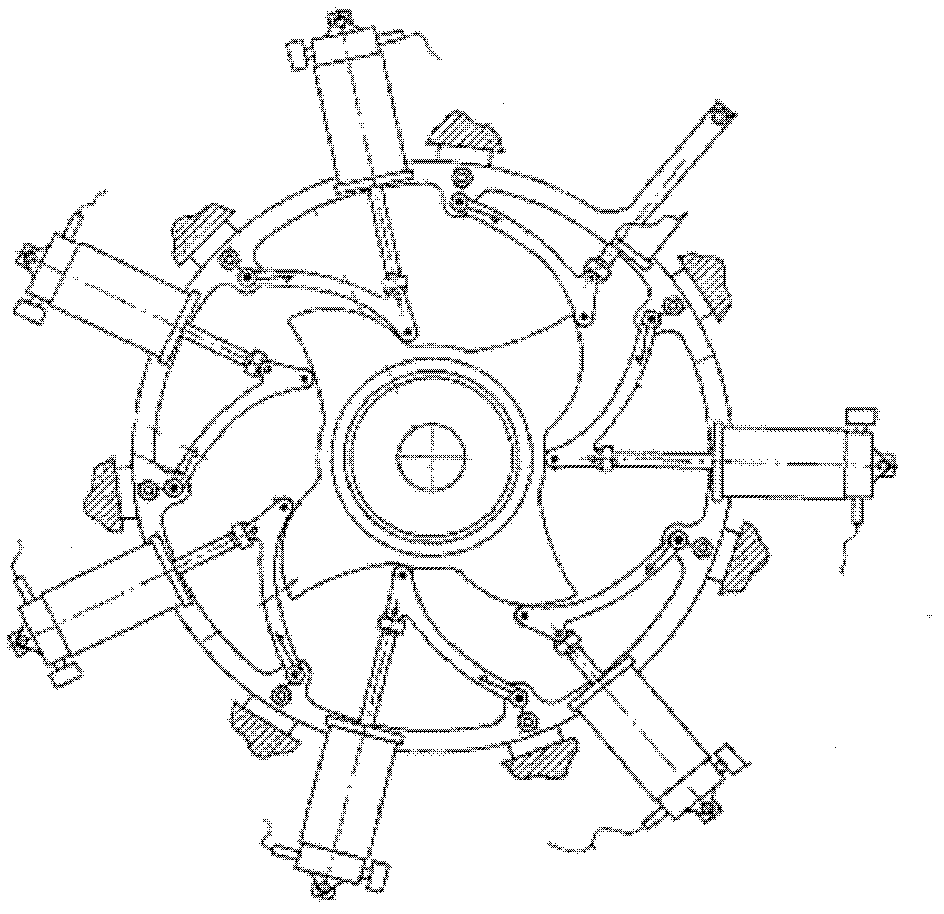

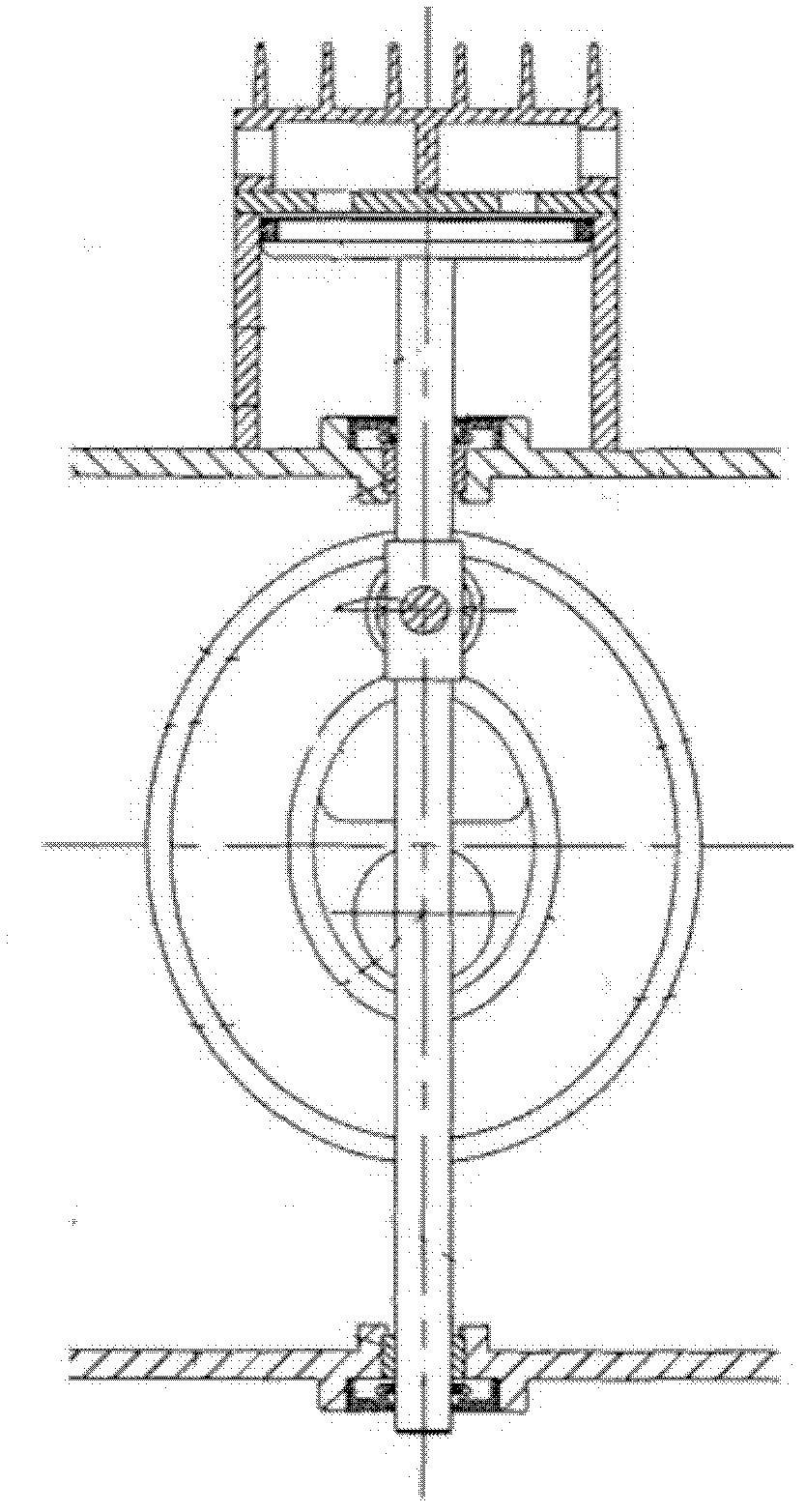

[0091] Such as image 3 Shown is a schematic diagram of the overall structure of the present invention.

[0092] A wind-powered air compressor shown in the figure mainly includes: a wind-driven transmission system, a steering shaft seat, an air compressor, an air storage chamber and an empennage lock device.

[0093] Wherein the wind power transmission system includes: fan blade 14, drive shaft 30, fan blade shaft seat 15 and empennage 1, drive shaft runs through fan blade shaft seat 15 and is fixedly connected with the drive wheel in air compressor casing 12, and empennage 1 passes through The empennage connecting rod 4 is fixed on one side of the air compressor casing 12, the empennage connecting rod is hinged with the casing 12, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com