Servo online oil sampling and controlling device and method

A sampling control and oil technology, applied in the direction of sampling devices, etc., can solve problems such as delays in the determination of mechanical equipment, and achieve the effects of long transmission distance, fast transmission speed, and flexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

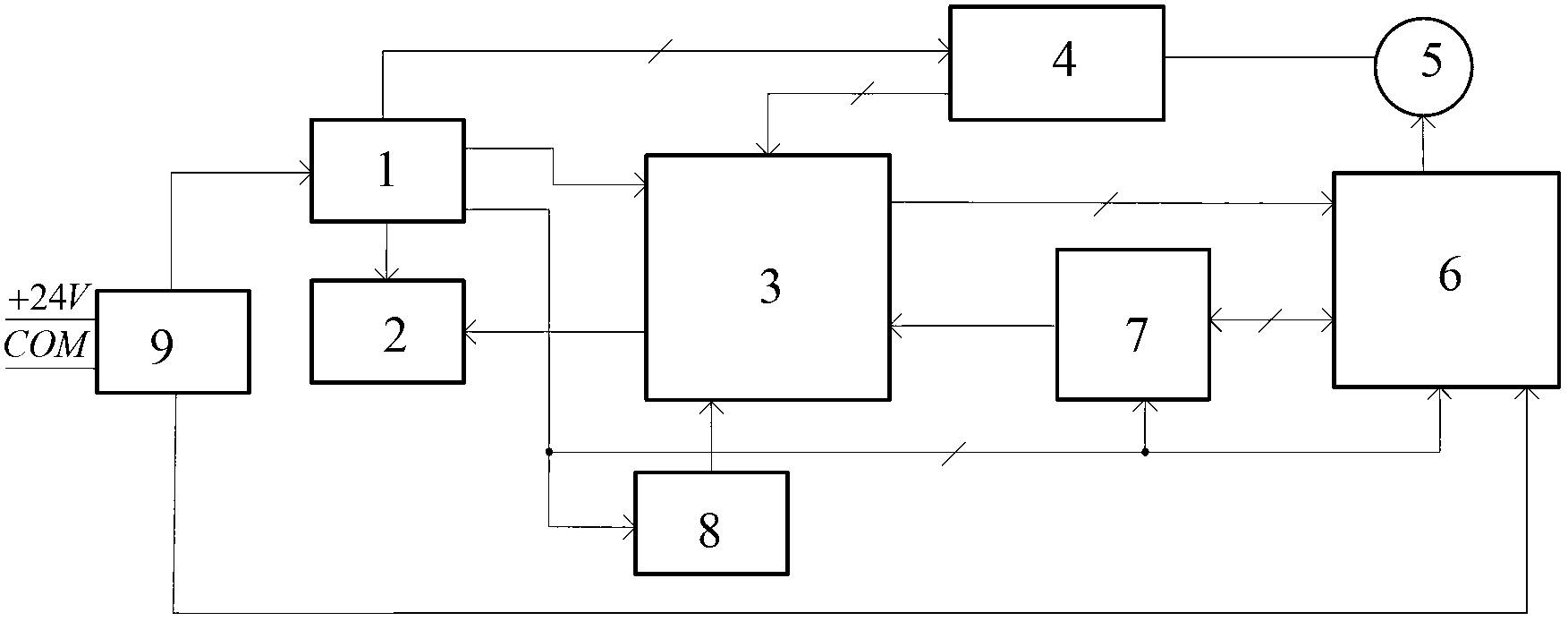

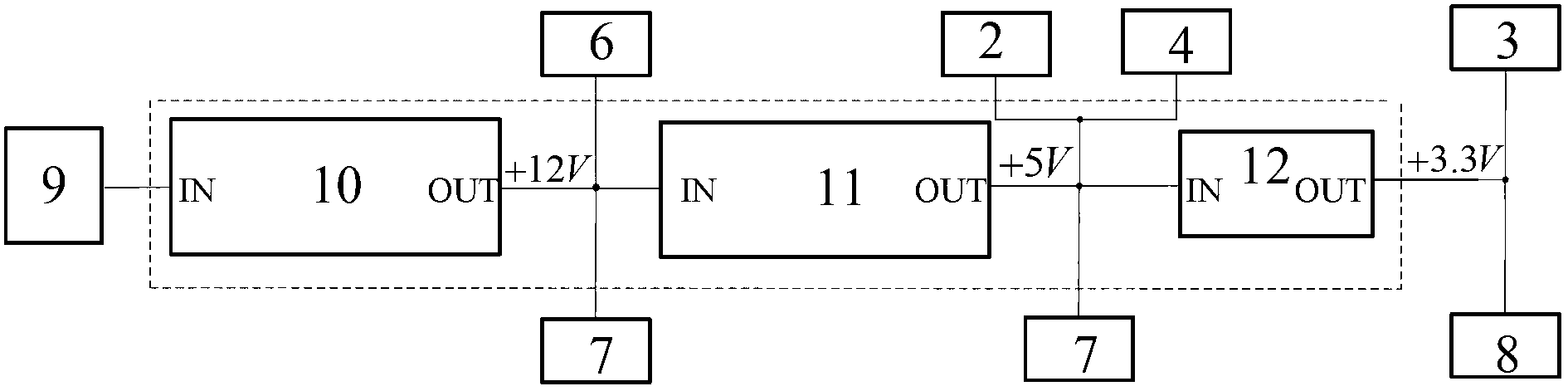

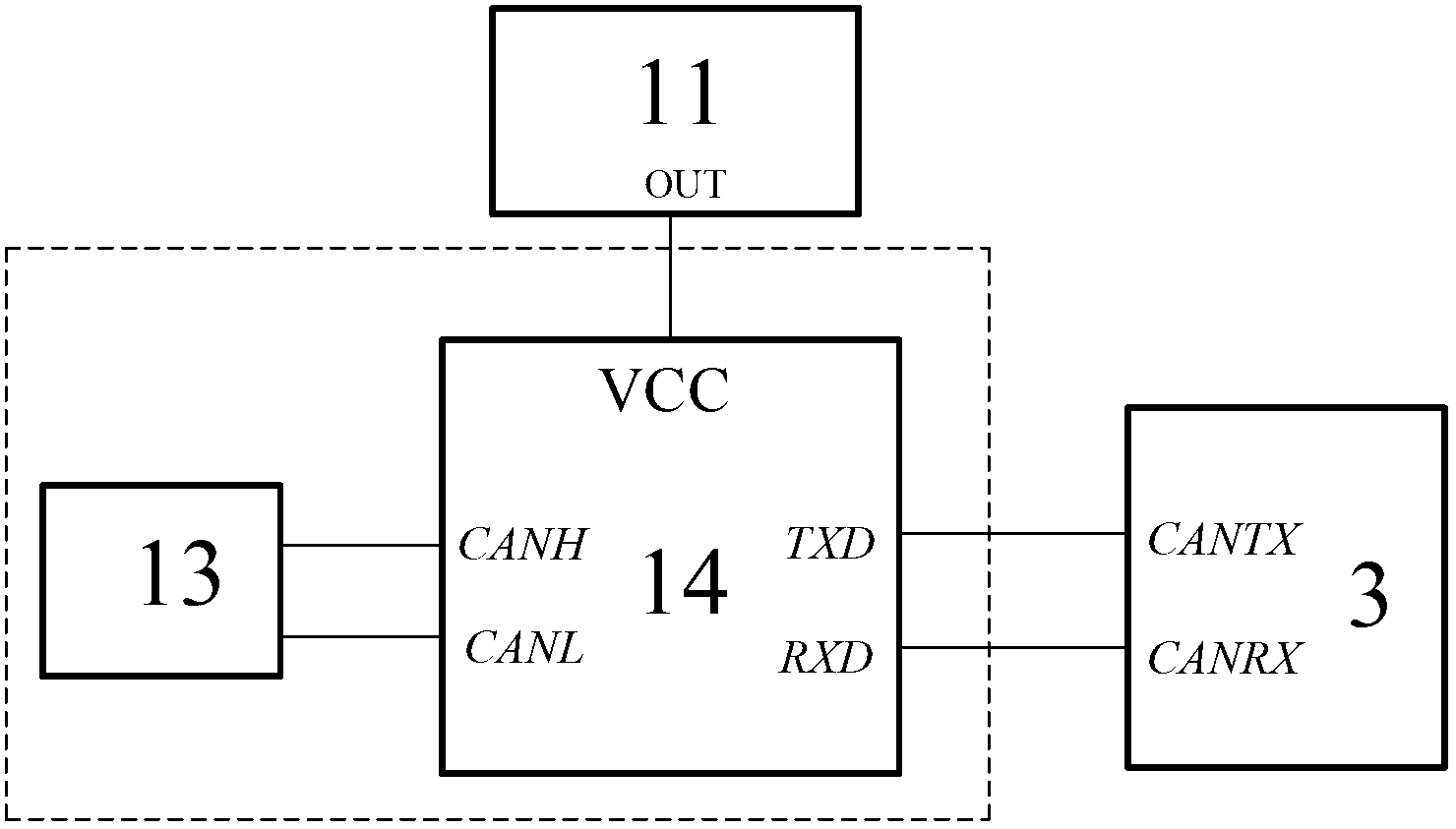

[0035] The structure of a servo online oil sampling control device in this embodiment is as follows figure 1 As shown, it includes a power conversion unit 1, a CAN communication unit 2, an ARM chip 3, an information acquisition feedback unit 4, a motor-type brushless DC pump 5, a control drive unit 6, a self-protection unit 7, a solenoid valve 8, and a DC power interface 9 . The power conversion unit 1 is connected to the CAN communication unit 2, the ARM chip 3, the information acquisition feedback unit 4, the control drive unit 6, the self-protection unit 7, the solenoid valve 8, and the DC power interface 9. The ARM chip 3 is respectively connected to the CAN communication unit 2 , Information collection and feedback unit 4, control drive unit 6, self-protection unit 7, solenoid valve 8, and control drive unit 6 are respectively connected with self-protection unit 7, motor-type brushless DC pump 5, DC power interface 9, information collection and feedback The unit 4 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com