Method for preparing permutable multi-dye absorption layer co-sensitized thin film by electrochemical desorption method

A dye adsorption and desorption technology, which is applied in the cross field of electrochemistry and nanomaterials, can solve the problems that the structure of the adsorption layer cannot be optimized in depth, and the co-sensitization effect of the film is not good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

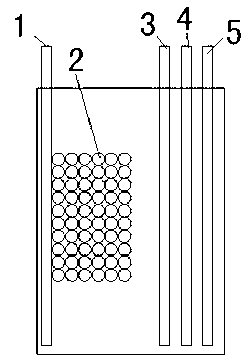

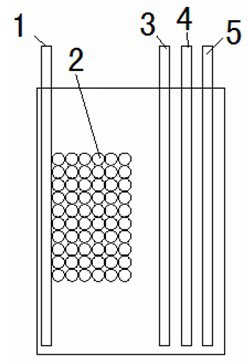

[0021] Method 1: Embedded preparation of co-sensitized films, such as figure 1 As shown, the TiO 2 The paste is printed on the upper part of the conductive substrate 1 and sintered at 510 °C for 30 minutes to form a 15 μm thick nanoporous TiO 2 film. Formation of single dye-sensitized TiO after immersion in dye a solution for 12 h 2 film. TiO with adsorbed dye a 2 The thin film 2 is used as the working electrode, the saturated calomel electrode 3 is used as the reference electrode, and the platinum ring 4 is used as the auxiliary electrode to form a three-electrode dye desorption system, and the electrolyte solution has a concentration of 0.3 M TBAPF 6 and LiClO 4 acetonitrile solution. A negative potential of -1.5 V was applied to the conductive substrate 1 (defined as TiO 2 front end of film 2), after adsorption on TiO 2 The dye a on the film 2 starts to desorb from the conductive substrate 1 . After applying the potential for 10 minutes, a dye blank layer of about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com