Manufacture method of metal-silicon oxide-metal capacitor

A technology of metal capacitors and manufacturing methods, applied in the field of microelectronics, can solve the problems of MIM capacitor breakdown voltage, leakage current difference, and poor uniformity of silicon nitride film, so as to improve electrical uniformity, reduce silicon-hydrogen bonds, and increase capacitance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in combination with principle diagrams and specific operation examples.

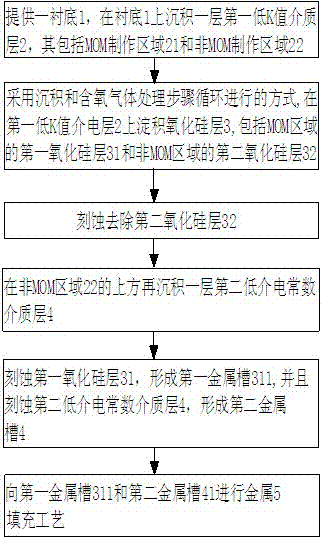

[0026] Such as figure 1 as well as Figures 2A-2H Shown in, the manufacture method of a kind of metal-silicon oxide-metal capacitor of the present invention specifically comprises the following steps:

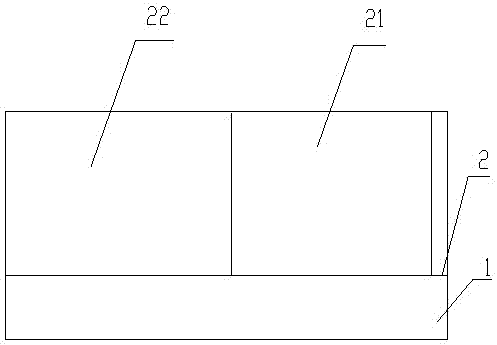

[0027] Step S1: Provide a substrate 1, and deposit a layer of first low dielectric constant (low K value) dielectric layer 2 on the substrate 1, the surface of the first low dielectric constant dielectric layer 2 includes metal-oxide- metal (MOM) region 21 and non-metal-oxide-metal (non-MOM) region 22;

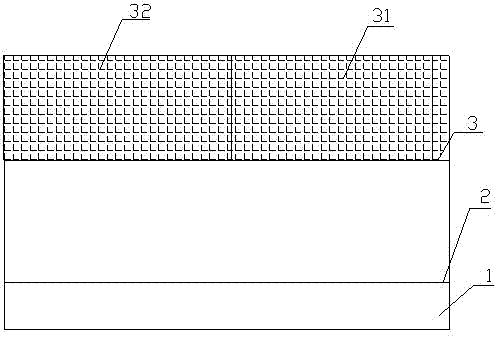

[0028] Step S2: Deposit a layer of silicon oxide layer 3 on the surface of the first low dielectric constant layer 2, the silicon oxide layer 3 is included in the first silicon oxide layer 31, which is located in the metal-oxide-metal (MOM) region 21 and A second silicon oxide layer 32 in the non-metal-oxide-metal (non-MOM) region. In this s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com