Method for sterilizing surface of space and sterilization system

A space and bactericide technology, applied in packaging sterilization, sanitary equipment for toilets, atomized substances, etc., can solve the problems of unsuitable sterilization objects, a large number of bactericides and cleaning water, poor sterilization efficiency, etc. Reduced personnel and man-hours, reduced human or environmental impact, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0057] The inventors of the present invention conducted the following experiments in order to confirm the relationship between the concentration of aqueous hydrogen peroxide solution and the bactericidal effect in a space surface sterilization method using a hydrogen peroxide aqueous solution spray followed by vaporization drying method.

[0058] As shown in Table 1, six kinds of aqueous hydrogen peroxide solutions having different concentrations of 0.1% by weight, 0.3% by weight, 1% by weight, 3% by weight, 10% by weight, and 30% by weight were prepared. Inoculate and dry Bacillus subtilis as the test bacterium on one side of a 10mm×10mm aluminum plate to make a test piece, and place the above-mentioned prepared hydrogen peroxide solution at a distance of 100mm from the test piece. Spray 2 times with a sprayer to make it adhere. The particle diameter of the fungicide is in the range of 1 to 30 μm, and the adhesion amount is set to 1 mg / cm 2 . figure 2 It is an enlarged pho...

experiment example 2

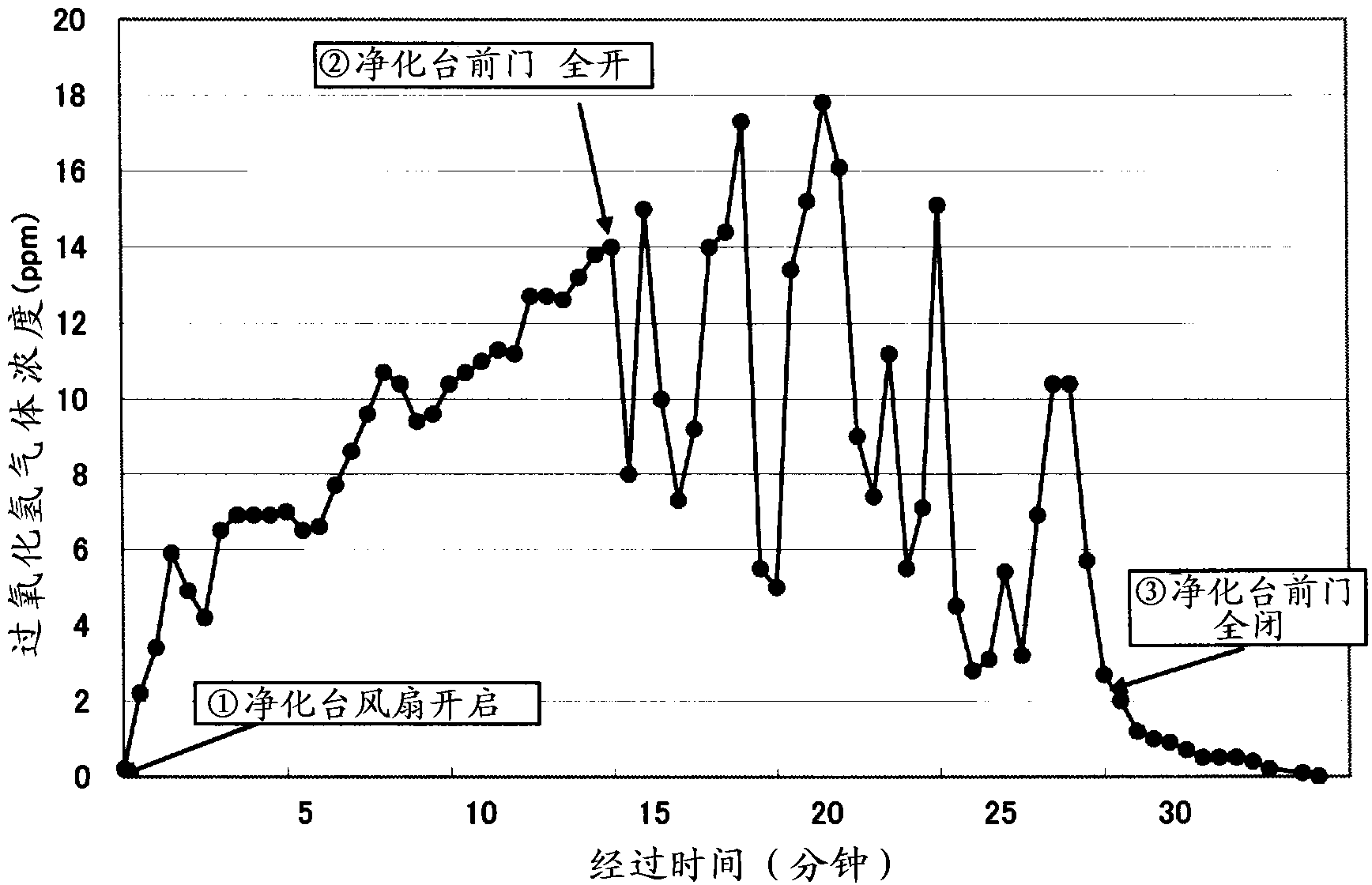

[0064] Furthermore, in order to confirm the safety to the operator in the sterilization by the hydrogen peroxide aqueous solution spray, the following experiment of measuring the hydrogen peroxide gas concentration in air-drying was performed.

[0065] Spraying place: Operation console of clean bench (manufactured by AIR TECH)

[0066] Blowing speed: about 0.45m / sec

[0067] Size: 1260mm×650mm

[0068] Hydrogen peroxide concentration: 3% by weight

[0069] Experimental method: The adhesion amount of the 3 wt% hydrogen peroxide aqueous solution to the entire clean table is 1 mg / cm 2 After spraying at a distance of 100mm from the operating table (visually confirm that the bactericide is evenly sprayed on one side of the operating table), let it air dry, and place the hydrogen peroxide concentration measuring device (Draeger) on the operating table. The hydrogen peroxide gas concentration in the atmosphere in the clean bench was recorded every 30 seconds.

[0070] Drying cond...

experiment example 3

[0081] An experiment was conducted to confirm the effective concentration for obtaining the bactericidal effect according to the type of chemical.

[0082] Spray liquid: hydrogen peroxide aqueous solution, peracetic acid aqueous solution, sodium hypochlorite aqueous solution

[0083] Test bacteria: Bacillus subtilis

[0084] Method: Inoculate the test bacteria on one side of an aluminum plate (test piece) of 10mm × 10mm, dry it, and spray the above-mentioned agents on each test piece to make it adhere to 1 mg / cm 2 , and after drying, the test piece was immersed in the culture medium and cultured. In addition, the dry state of a chemical|medical agent was visually confirmed.

[0085] Drying conditions: Close the front door of the purification table and dry (humidity 60%RH, temperature 25℃)

[0086] Drying time: 30 minutes

[0087] Culture conditions: Glucose tryptone broth medium, cultured at 35°C

[0088] The results are shown in Table 3.

[0089] table 3

[0090]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Drying time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com