Pure copper plate production method, and pure copper plate

A manufacturing method, copper plate technology, applied in metal rolling, vacuum evaporation plating, coating, etc., to achieve the effect of suppressing the generation of insoluble residues and improving the uniformity of in-plane dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] Next, an embodiment of the present invention will be described.

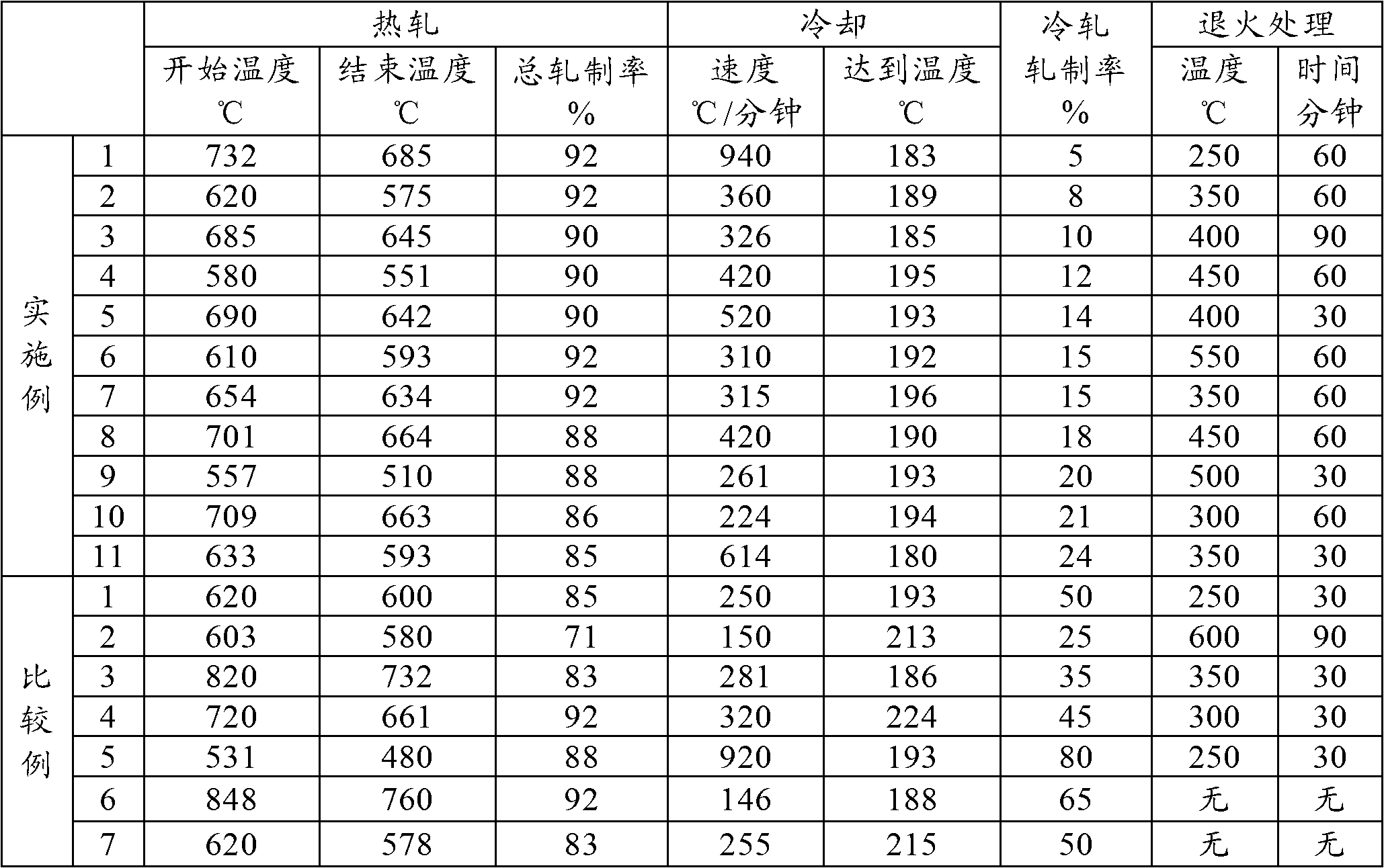

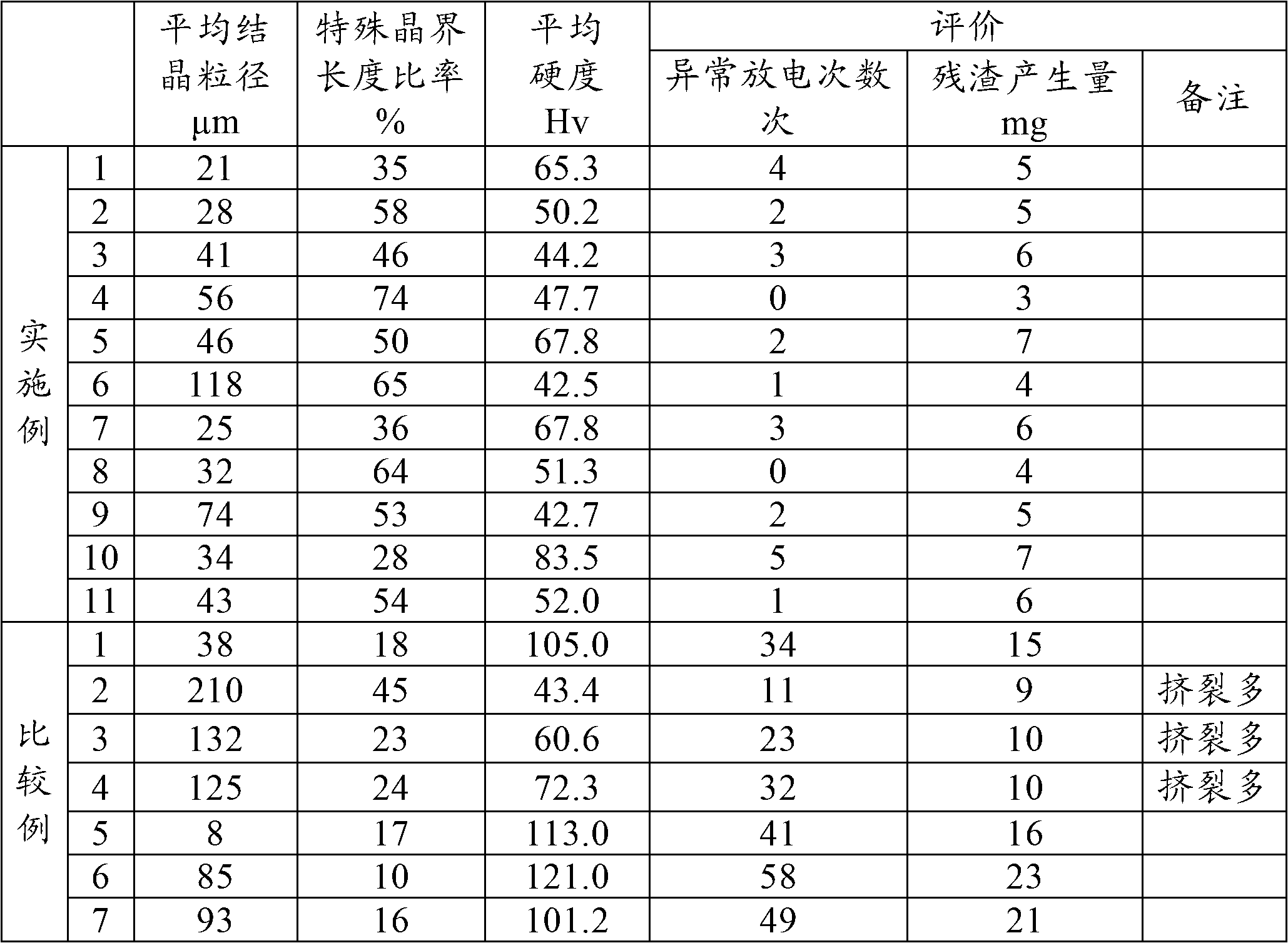

[0052] The raw material for rolling is an ingot of oxygen-free copper for electron tubes (purity 99.99wt% or more). The size of the raw material before rolling was 650 mm wide×900 mm long×290 mm thick, and various conditions after hot rolling were combined as shown in Table 1 to produce pure copper plates. In addition, the temperature measurement was performed by measuring the surface temperature of the rolled sheet using a radiation thermometer.

[0053] [Table 1]

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com