Mixed feed required by nutrition of young Chinese soft-shelled turtles with weight between 150g and 250g and preparation method

A technology for compound feed and Chinese soft-shelled turtle, which is applied in animal feed, animal feed, application and other directions, can solve the problems of Chinese soft-shelled turtle's nutritional value and commercial value discount, high feeding cost, and difficult to store feed, etc., to improve meat quality and nutritional value. The effect of promoting breeding efficiency and enhancing commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

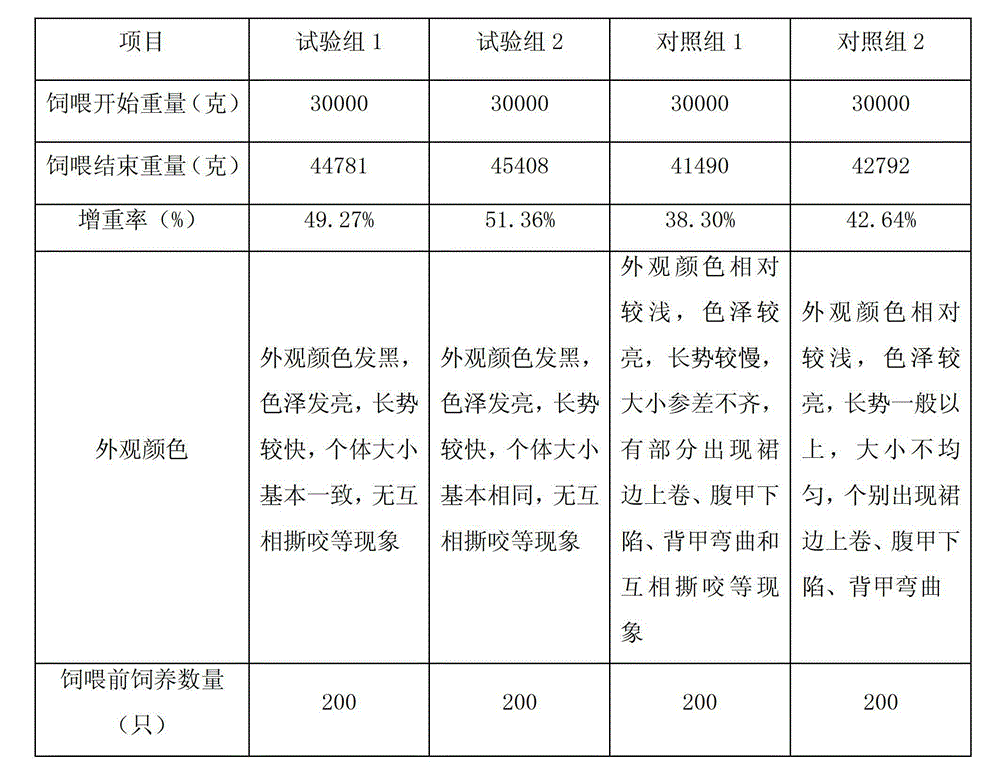

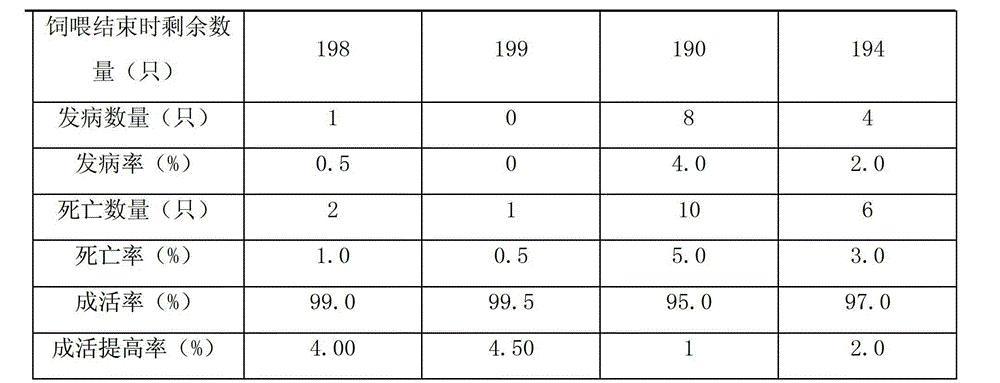

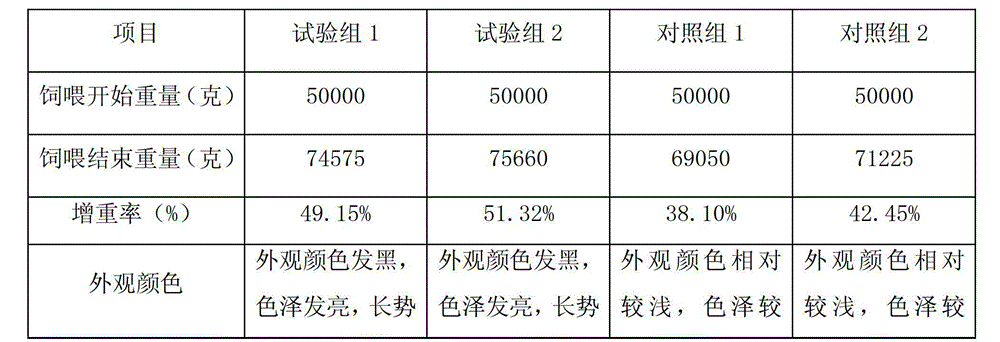

Examples

Embodiment 1

[0018] Take the raw materials according to the following proportions by weight:

[0019] 30 parts of flour, 20 parts of fresh feed, 2 parts of hemoglobin powder, 8 parts of seasonal fresh vegetables, 10 parts of starch, 4 parts of yeast powder, 2 parts of garlic powder, 1 part of immune polysaccharide, 1 part of mineral trace elements, multivitamins 0.5 parts, 0.5 parts of prebiotics, 1 part of salt, 1 part of various amino acids.

[0020] The preparation method is as follows:

[0021] The above-mentioned raw materials weighed were superfinely pulverized to 80 meshes, and then placed in a blade mixer for mixing. During the mixing process, hot water at a temperature of 60°C was added by spraying. Layer thermal insulation steam modulator for the first aging, and then enter the granulator for granulation; after granulation, carry out the second aging in the wooden box, then cool and dry to obtain dry granules, and finally dry the granules through Ultrafine grinding to 80 meshes...

Embodiment 2

[0023] Take the raw materials according to the following proportions by weight:

[0024] 40 parts of flour, 30 parts of fresh feed, 5 parts of hemoglobin powder, 12 parts of seasonal fresh vegetables, 15 parts of starch, 8 parts of yeast powder, 5 parts of garlic powder, 2 parts of immune polysaccharide, 2 parts of mineral trace elements, multivitamins 0.8 parts, 1 part of prebiotics, 2 parts of salt, 2 parts of various amino acids.

[0025] The preparation method is as follows:

[0026] The above-mentioned raw materials weighed were superfinely pulverized to 100 mesh, and then placed in a blade mixer for mixing. During the mixing process, hot water at a temperature of 70°C was added by spraying. Layer thermal insulation steam modulator for the first aging, and then enter the granulator for granulation; after granulation, carry out the second aging in the wooden box, then cool and dry to obtain dry granules, and finally dry the granules through Superfine grinding to 100 mesh...

Embodiment 3

[0028] Take the raw materials according to the following proportions by weight:

[0029] 35 parts of flour, 25 parts of fresh feed, 4 parts of hemoglobin powder, 10 parts of seasonal fresh vegetables, 13 parts of starch, 6 parts of yeast powder, 4 parts of garlic powder, 1.5 parts of immune polysaccharide, 1.5 parts of mineral trace elements, multivitamins 0.6 parts, 0.8 parts of prebiotics, 1.5 parts of salt, 1.5 parts of various amino acids.

[0030] The preparation method is as follows:

[0031] The above-mentioned raw materials weighed were superfinely pulverized to 100 mesh, and then placed in a blade mixer for mixing. During the mixing process, hot water at a temperature of 50°C was added by spraying. Layer thermal insulation steam modulator for the first aging, and then enter the granulator for granulation; after granulation, carry out the second aging in the wooden box, then cool and dry to obtain dry granules, and finally dry the granules through Superfine grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com