Ultrasonic atomizer

An ultrasonic and nebulizer technology, applied in the field of ultrasonic nebulizers, can solve problems such as fan noise, large volume, unsuitable for miniaturization of electrical appliances, etc., and achieve the effects of high sensitivity, improved performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

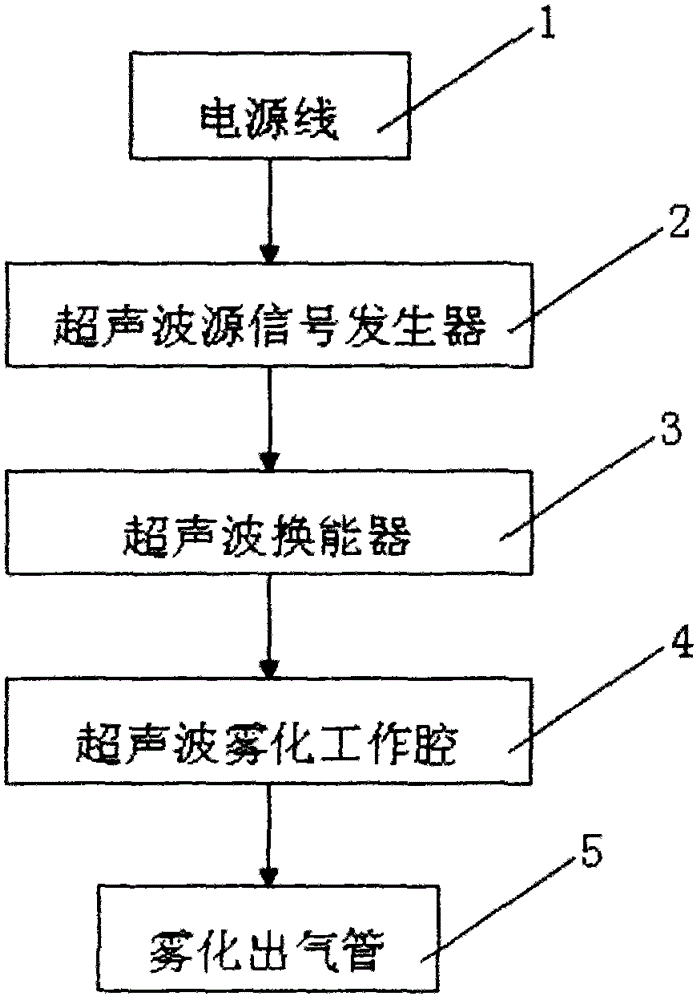

[0043] refer to figure 1 As shown, an ultrasonic atomizer of the present invention includes a power cord 1 connected in sequence to provide electric energy, an ultrasonic source signal generator 2 that receives electric energy and converts electric energy into electric signals, receives electric signals and converts electric signals into high The ultrasonic transducer 3 oscillating at high frequency, the ultrasonic atomizing working cavity 4 filled with liquid, and the atomizing outlet pipe 5 for discharging the mist converted from liquid through high frequency oscillation, the liquid refers to water in this embodiment.

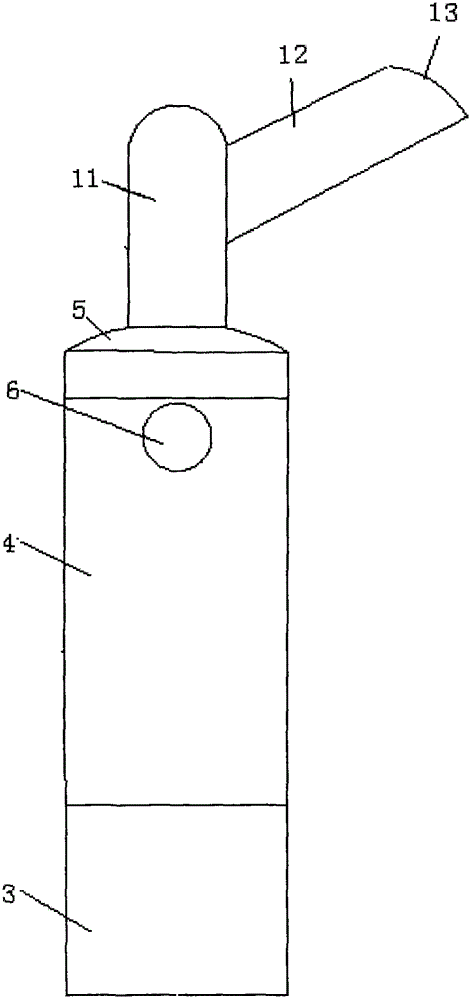

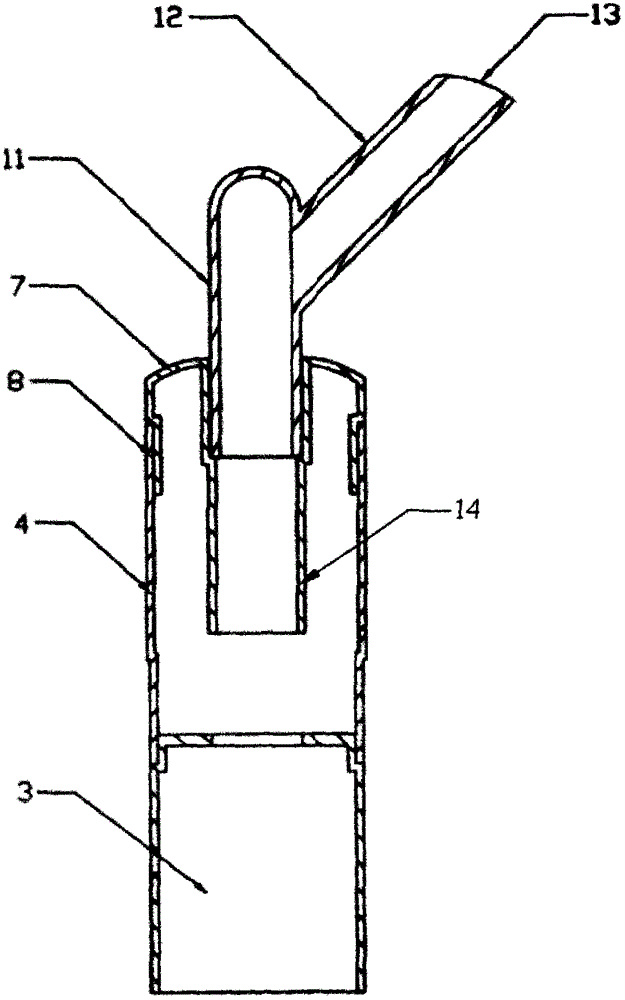

[0044] refer to Figures 2 to 4 As shown, the ultrasonic atomization working chamber 4 is a cylindrical shape with a hollow interior and open up and down. The outer wall of the ultrasonic atomization working chamber 4 is provided with an air inlet 6 for air to enter the chamber, and the air inlet 6 is circular in this embodiment. The atomizing air outlet pi...

Embodiment 2

[0075] refer to Figure 5 As shown, this embodiment is basically the same as Embodiment 1, the only difference is that a medicine cup 15 containing liquid medicine is arranged in the ultrasonic atomization working chamber 4, and the opening end of the medicine cup 15 is connected with the ultrasonic atomization working chamber. The inner walls of 4 are connected, that is, the medicine cup 15 completely separates the medicine liquid inside from the water in the ultrasonic atomization working chamber 4. The opening of the medicine cup 15 faces the atomization outlet pipe 5, so that the ultrasonic energy generated by the ultrasonic transducer 3 passes through the medicine cup 15 through the water in the ultrasonic atomization working chamber 4 to atomize the medicine liquid, and finally passes through the atomization outlet pipe 5 discharge. This ultrasonic nebulizer with medical effect has a novel structure, small atomized particles and convenient operation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com