Gear milling spindle box directly driven by torque motor

A technology of torque motor and spindle box, which is used in driving devices, metal processing machinery parts, manufacturing tools, etc., can solve the problems of vibration lines on the machined surface, easy pitting of gears, and poor rigidity, so as to avoid impact pitting and transmission. Short path, improved surface roughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation plan

[0029] In order to further understand the content, characteristics and functions of the present invention, through the following implementation examples, and in conjunction with the accompanying drawings, the description is as follows:

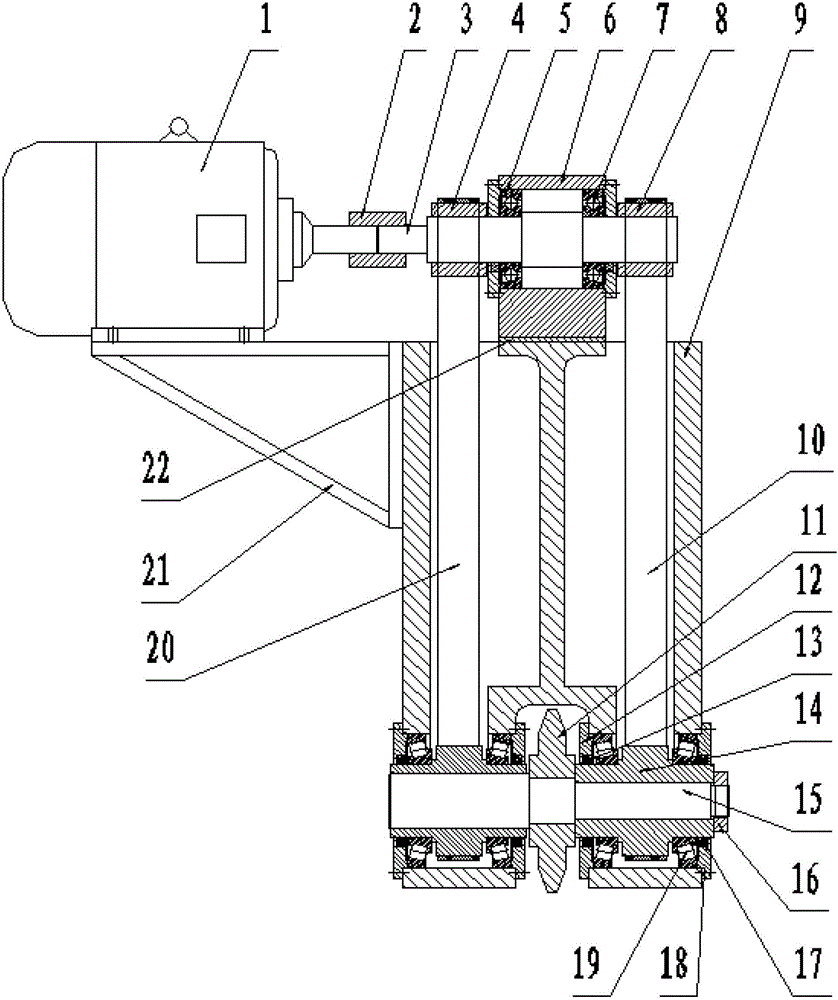

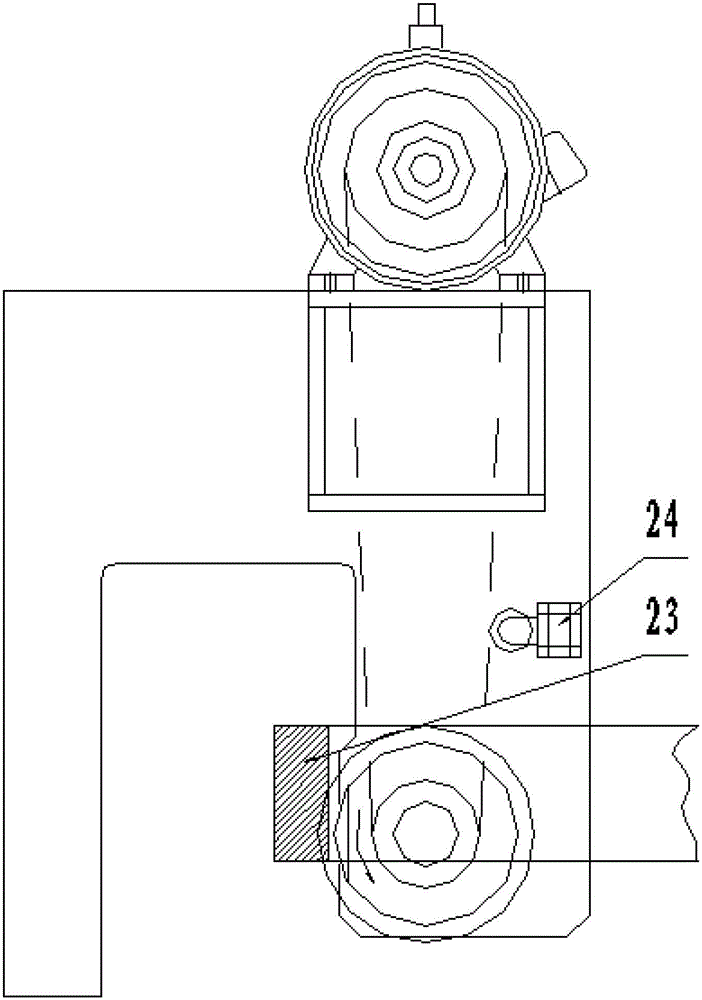

[0030] A torque motor direct-drive milling gear spindle box, comprising a low-speed high-torque torque motor 1, an active synchronous pulley shaft 3, a first active synchronous pulley 4, a second active synchronous pulley 8, a main shaft case 9, a motor bracket 21, The first synchronous belt 10, the second synchronous belt 20, the disc milling cutter 11, the passive synchronous pulley shaft 14 and the tool bar 15, the low-speed high-torque torque motor 1 is connected with the active synchronous pulley shaft 3, and the active synchronous pulley shaft 3 The two ends are respectively provided with a first active synchronous pulley 4 and a second active synchronous pulley 8, the first active synchronous pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com